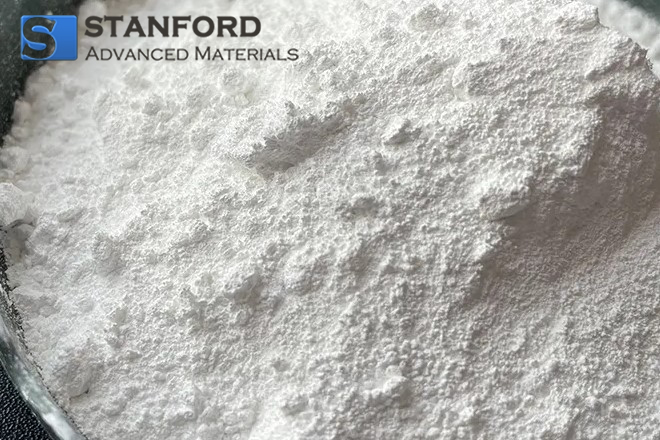

Spherical Alumina Powder (Surface Treatment) Description

Spherical Alumina Powder (Surface Treatment) is a series of products after surface treatment with special chemicals. It exhibits lower viscosity and high loading compacity in organic resins. It still remains high spheroidization rate, high filling ratio, and high thermal conductivity. The surface treatment of the filler will improve the compatibility of the fillers and polymer matrix, and also improve the thermal conductivity.

Spherical Alumina Powder (Surface Treatment) Specifications

|

Main Composition

|

Al2O3

|

|

Color

|

White

|

|

True Density (g/cm3)

|

~3.8

|

|

Al2O3 Content

|

>99.9 %

|

|

Surface Treatment

|

As required

|

For Specifications of other types, please click here.

Spherical Alumina Powder (Surface Treatment) Applications

1. Polishing and buffing: Spherical aluminum oxide powders are widely used as a key ingredient in polishing and buffing compounds. Their uniform particle size and excellent abrasion resistance make them very effective in the surface treatment of materials such as metals, plastics, glass, and ceramics. By controlling the particle size and concentration of the powder, different surface finishes and precision requirements can be achieved.

2. Surface Cleaning and Pretreatment: Spherical aluminum oxide powders can be used as a surface cleaning and pretreatment medium. They are effective in removing dirt, oxidized layers, and other impurities from the surface, providing a clean surface for subsequent coating or bonding processes.

3. Coating and Painting: Spherical aluminum oxide powders can be added to coatings as fillers or functional additives during the coating and painting process. They improve the abrasion resistance, corrosion resistance, and surface hardness of the coating while enhancing the gloss and smoothness of the coating.

4. Polishing of ceramics and glass: Spherical alumina powders are used to polish and remove surface imperfections in ceramic and glass manufacturing processes. They provide efficient surface finishing and brightening to achieve a high-quality surface finish on manufactured products.

5. Precision machining of electronic devices: In the manufacture of electronic devices, spherical alumina powders are used in precision machining processes such as polishing and surface conditioning of glass substrates. They ensure the flatness and precision of the surface of the equipment and help to improve the performance and reliability of electronic products.

6. Metal Processing: In metal processing, spherical alumina powders can be used as polishing agents and grinding media for removing scratches, oxidation layers, and inhomogeneities on metal surfaces, enhancing the surface quality and precision of parts.

7. Plastic Molding: In the plastic molding process, spherical alumina powder is used as a polishing agent and surface treatment agent to enhance the surface finish and overall appearance of plastic products.

Spherical Alumina Powder (Surface Treatment) Packaging

Our Spherical Alumina Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Spherical Alumina Powder (Surface Treatment) FAQs

Q1: How does spherical alumina powder improve thermal conductivity in materials?

A: The high thermal conductivity of alumina helps dissipate heat effectively. Its spherical shape ensures uniform distribution and minimizes voids in composite materials, leading to enhanced thermal management.

Q2: How is spherical alumina powder produced?

A: It is typically produced through methods such as spray drying, flame synthesis, or plasma processing. These methods help achieve the desired spherical shape and high purity.

Q3: What particle sizes are available for spherical alumina powder?

A: Spherical alumina powder is available in various particle sizes, ranging from nanometers to micrometers, depending on the specific application requirements.