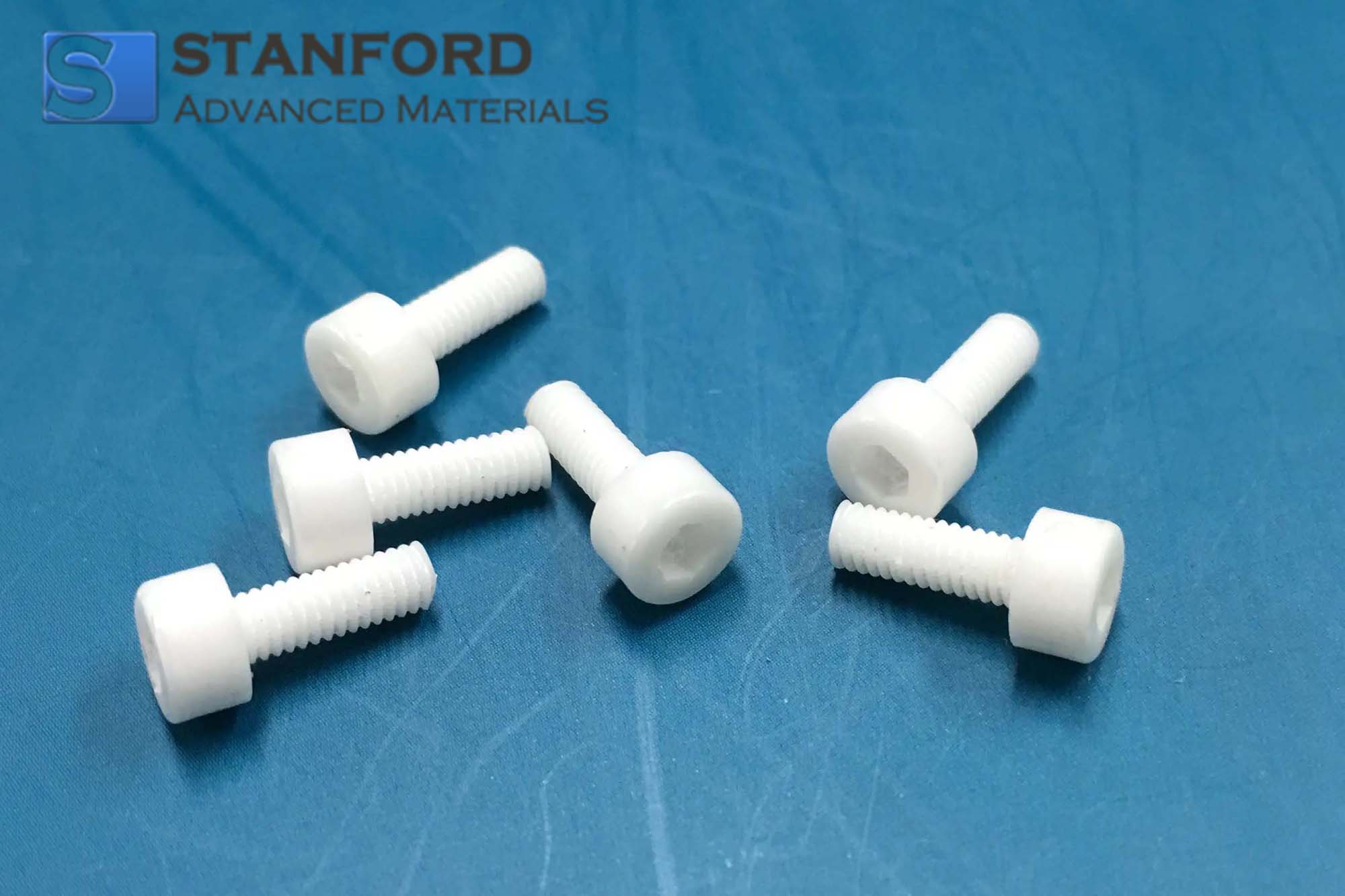

AC0918 Alumina Fasteners

| Catalog No. | AC0918 |

| Material | Al3O2 |

| Standard | Metric, America |

| Color | White |

| MSDS/SDS |

Stanford Advanced Materials (SAM) provides ceramic products, including fasteners, bolts, screws and nuts in both American and metric standard. Non-standard custom production is available for large quantity. Typical materials are 99.8% alumina and stabilized zirconia.

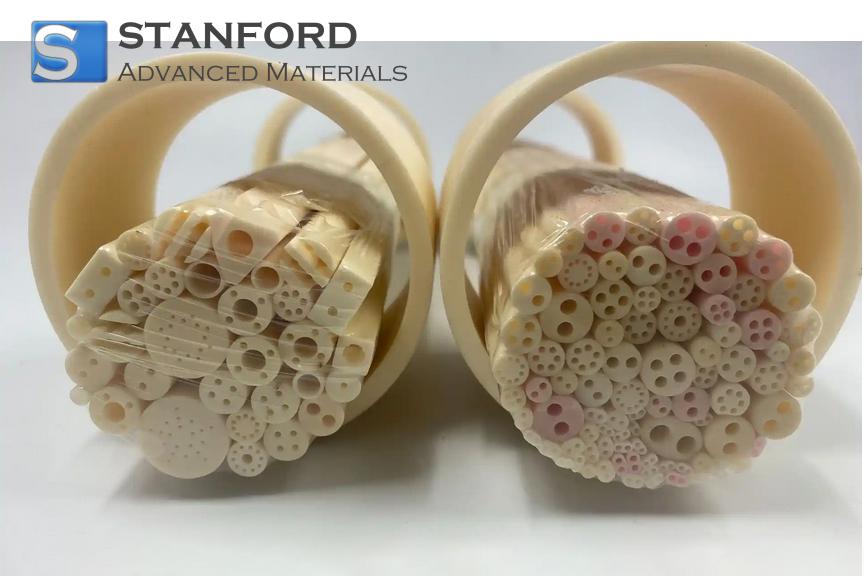

Related products: Alumina Plate, Alumina Tube, Alumina Custom Parts

Alumina Fasteners Description

Alumina Fasteners, as a fine ceramic material, are widely used in a lot of industries. This material has superb performance in electrical insulation, high chemical resistance, and low thermal expansion. High-purity alumina materials are excellent for making parts for CVD, ion implants, photolithography, and semiconductor parts. In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles, and insulators. Alumina Fasteners are made of materials with very low thermal expansion coefficients and excellent wear resistance.

Alumina Fasteners Specifications

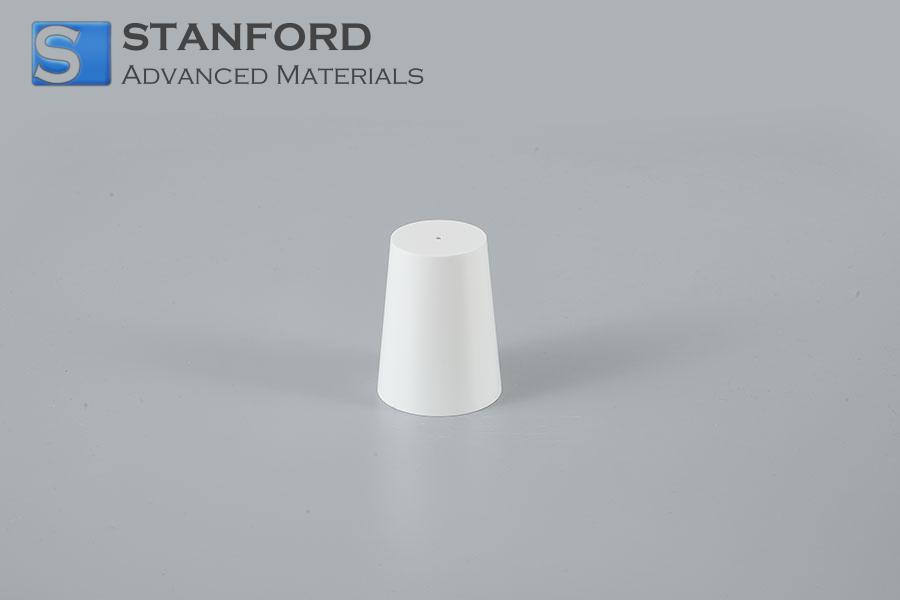

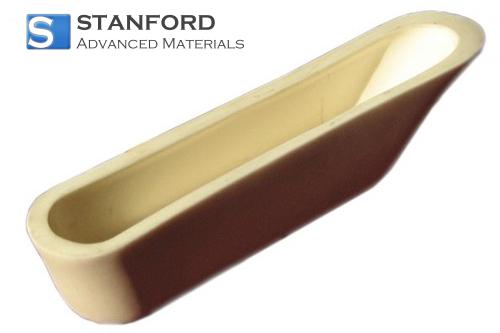

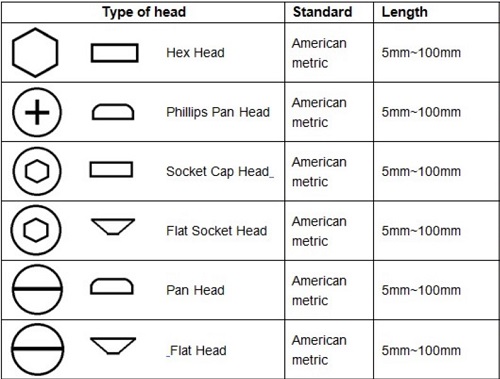

Alumina Fasteners Shapes

Alumina Fasteners Properties

|

Composition |

UNIT |

Al95 |

Al99 |

Al997 |

|

Al2O3 Content |

% |

95 |

99 |

99.7 |

|

Color |

|

White |

Ivory |

Ivory |

|

Tensile Strength |

Kpsi |

32 |

38 |

36 |

|

Flexural Strength |

Kpsi |

52 |

55 |

54 |

|

Compressive Strength |

Kpsi |

300 |

377 |

350 |

|

Density |

g/cc |

3.70 |

3.90 |

3.92 |

|

Hardness |

HV, GPa |

13.8 |

17.2 |

18 |

|

Thermal Conductivity |

W/(m K) |

25 |

30 |

30 |

|

C.O.T.E. |

In / In°C (x10^-6) |

7.7 |

7.8 |

7.8 |

|

Working Temperature |

°C |

1500 |

1650 |

1750 |

|

Dielectric Constant |

|

9.5 |

9.7 |

9.8 |

|

Volume Resistivity (25°C) |

Ohm-cm |

>10^14 |

>10^14 |

>10^14 |

Prototyping service also available for other ceramics material

Alumina Fasteners Applications

1. High-Temperature Environments: Alumina fasteners are used in high-temperature applications such as furnaces, kilns, and heat treatment equipment where metal fasteners fail due to oxidation and loss of strength.

2. Chemical Processing: Employed in chemical processing equipment, alumina fasteners resist corrosion from aggressive chemicals, acids, and alkalis, making them suitable for use in reactors, storage tanks, and pipelines.

3. Electrical Insulation: Due to their excellent electrical insulating properties, alumina fasteners are used in electrical and electronic equipment to secure components and maintain electrical isolation, especially in high-voltage applications.

4. Semiconductor Manufacturing: Used in the semiconductor industry where high purity and resistance to thermal and chemical processes are critical. Alumina fasteners help secure equipment and components in cleanroom environments.

5. Aerospace and Defense: Applied in aerospace and defense applications where lightweight, high-strength, and temperature-resistant materials are required for components exposed to extreme conditions.

6. Medical and Dental Equipment: Used in medical and dental instruments and devices due to their biocompatibility, resistance to sterilization processes, and ability to maintain structural integrity over time.

7. Analytical and Laboratory Equipment: Employed in laboratory and analytical equipment where resistance to high temperatures, chemicals, and thermal shock is essential for accurate and reliable performance.

8. Mechanical and Structural Components: Utilized in mechanical and structural applications that require high strength, wear resistance, and stability under thermal cycling, such as in motors, pumps, and machinery.

9. Optical and Laser Systems: Used in optical and laser systems for securing components where thermal stability and minimal thermal expansion are critical to maintaining alignment and performance.

Alumina Fasteners Packing

Our Alumina Fasteners are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!