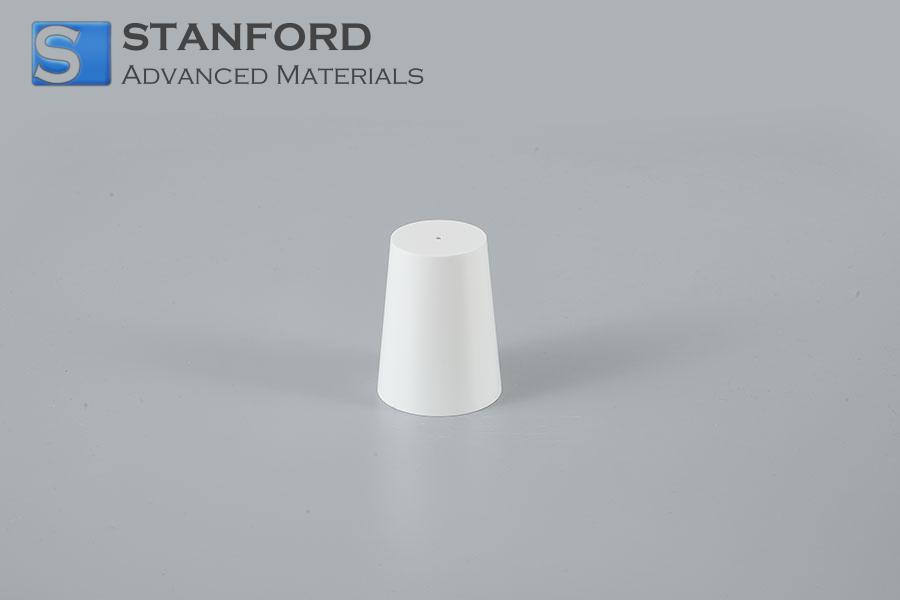

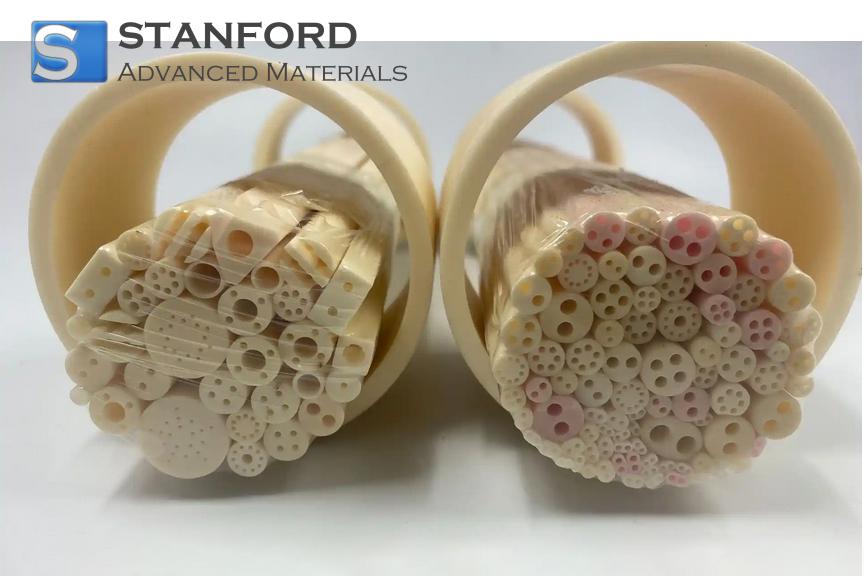

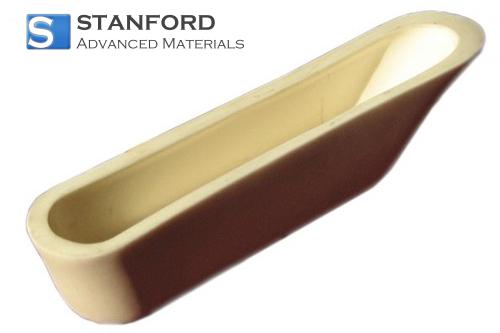

AC0927 Alumina Complex Shapes, Al2O3 Ceramic

| Catalog No. | AC0927 |

| Material | Al2O3 |

| Purity | 95% 99% 99.7% |

| Density | 3.8~3.9 g/cm3 |

Alumina complex shapes are a group of aluminum oxide ceramic products. SAM is a leading supplier and manufacturer of alumina complex shapes and a wide variety of Alumina products. Custom manufacturing is always available.

Related products: Alumina Mortar and Pestle Set, Alumina Crucible, Alumina Custom Parts

Alumina Complex Shapes Description

Alumina complex shapes refer to intricate or custom-designed structures made from alumina, which is a ceramic material primarily composed of aluminum oxide (Al2O3). Alumina is known for its exceptional strength, hardness, and thermal stability, making it suitable for a wide range of industrial applications.

Alumina Complex Shapes Specification

|

Composition |

UNIT |

Al95 |

Al99 |

Al997 |

|

Al2O3 Content |

% |

95 |

99 |

99.7 |

|

Color |

|

White |

Ivory |

Ivory |

|

Tensile Strength |

Kpsi |

32 |

38 |

36 |

|

Flexural Strength |

Kpsi |

52 |

55 |

54 |

|

Compressive Strength |

Kpsi |

300 |

377 |

350 |

|

Density |

g/cc |

3.70 |

3.90 |

3.92 |

|

Hardness |

HV, GPa |

13.8 |

17.2 |

18 |

|

Thermal Conductivity |

W/(m K) |

25 |

30 |

30 |

|

C.O.T.E. |

In / In°C (x10^-6) |

7.7 |

7.8 |

7.8 |

|

Working Temperature |

°C |

1500 |

1650 |

1750 |

|

Dielectric Constant |

|

9.5 |

9.7 |

9.8 |

|

Volume Resistivity (25°C) |

Ohm-cm |

>10^14 |

>10^14 |

>10^14 |

Alumina Complex Shapes Applications

Aerospace Components: Used in aerospace applications for parts that require high strength, thermal stability, and resistance to wear and corrosion. These components can include nozzles, insulators, and structural supports.

2. Medical Devices: Employed in medical devices and implants, such as dental prosthetics, hip replacements, and surgical instruments, where biocompatibility, high strength, and resistance to wear and sterilization processes are critical.

3. Semiconductor Manufacturing: Utilized in semiconductor fabrication equipment for components like wafer carriers, insulators, and substrates, benefiting from their purity, electrical insulation properties, and resistance to high temperatures and corrosive chemicals.

4. Electrical and Electronic Insulators: Applied in electrical and electronic applications as insulators, substrates, and heat sinks, where high dielectric strength, thermal conductivity, and stability are essential.

5. Chemical Processing Equipment: Used in chemical processing industries for components such as catalyst supports, reaction vessels, and protective liners, where resistance to high temperatures, corrosion, and wear is necessary.

6. Wear-Resistant Parts: Employed in various industrial applications requiring wear-resistant parts, such as pump seals, valve seats, and bearing components, where prolonged exposure to abrasive conditions demands durable materials.

7. Thermal Insulators: Utilized in high-temperature environments as thermal insulators and protective barriers in furnaces, kilns, and other heat treatment equipment, where thermal shock resistance and stability are crucial.

8. Optical and Laser Components: Used in optical and laser systems for components like lenses, reflectors, and supports, benefiting from alumina’s ability to withstand high temperatures and provide precise, stable performance.

9. Energy and Power Generation: Applied in power generation equipment, including components for nuclear reactors, turbines, and fuel cells, where high strength, thermal stability, and corrosion resistance are vital.

10. Automotive Industry: Used in the automotive industry for various components such as sensors, spark plugs, and exhaust systems, where high thermal resistance and mechanical strength are required.

11. Analytical Instruments: Employed in analytical instruments and laboratory equipment for components like crucibles, sample holders, and mixing tools, where chemical inertness and high-temperature performance are essential.

12. Environmental and Water Treatment: Used in environmental and water treatment systems for components that handle corrosive fluids and gases, ensuring long-term durability and performance in harsh conditions.

Alumina Complex Shapes Packaging

Our Alumina complex shapes are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

Prototyping service also available for other ceramics material

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!