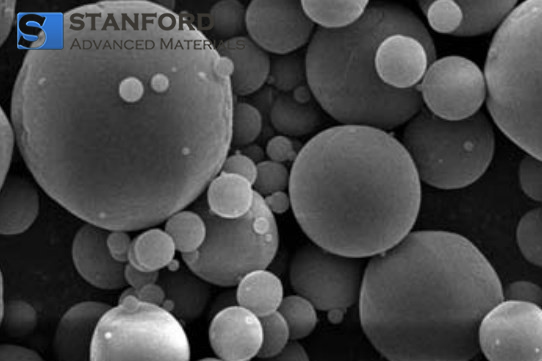

Spherical Alumina Powder (Mixed) Description

Spherical Alumina Powder (Mixed) is formulated by blending SSAC Series Powder to enhance thermal conductivity performance. It features a high spheroidization rate, optimal filling ratio, and excellent thermal conductivity. To enhance thermal conductivity efficiency through phonon conduction channels, it is common practice to utilize a mixed composition of fillers with varying particle sizes, reducing inter-particle gaps for improved heat transfer.

Spherical Alumina Powder (Mixed) Specifications

|

Item

|

Unit

|

SSAM-5M5

|

SSAM-10M6

|

|

Particle Size

|

D10

|

μm

|

1.5

|

1.49

|

|

D50

|

μm

|

5.73

|

8.91

|

|

D90

|

μm

|

11.08

|

17.88

|

|

Specific Surface Area

|

m2/g

|

0.36

|

0.26

|

|

Electric Conductivity

|

μS/cm

|

4.23

|

3.74

|

|

pH Value

|

-

|

7.58

|

7.59

|

|

Moisture

|

%

|

0.03

|

0.03

|

|

True Density

|

g/cm3

|

3.76

|

3.8

|

|

Spheroidization rate

|

%

|

96

|

96

|

|

Chemical Composition

|

Al2O3

|

%

|

99.93

|

99.94

|

|

SiO2

|

ppm

|

415

|

333

|

|

Fe2O3

|

ppm

|

174

|

163

|

|

Na2O

|

ppm

|

111

|

104

|

For Specifications of other types, please click here.

Spherical Alumina Powder (Mixed) Applications

1. Fillers and Reinforcing Agents: Spherical alumina powders are commonly used as fillers or reinforcing agents, and can be added to plastics, rubbers, and composites to enhance the strength, hardness, and abrasion resistance of the material.

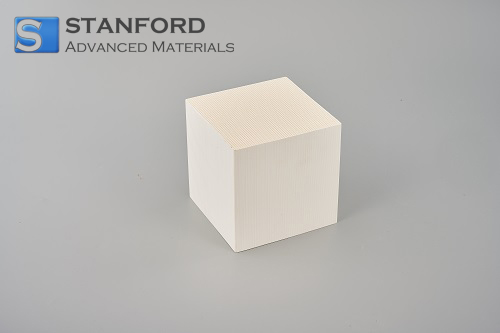

2. Ceramics Manufacturing: In the ceramics industry, spherical alumina powders are used as glazes and ceramic raw materials, providing uniform particle distribution and high purity for the manufacture of high-quality ceramic tiles, ceramic fittings, and other refractory products.

3. Abrasives and Polishes: Due to their uniform spherical particles and excellent abrasion resistance, spherical alumina powders are widely used in abrasives and polishes for the processing and surface treatment of metals, glass, and other materials.

4. Catalysts: In the chemical industry, spherical alumina powder is used as a carrier for catalysts to provide high surface area and chemical stability for the potentiation of various catalytic reactions.

5. Electronic Materials: In the electronics industry, spherical alumina powder is used as a key component in electronic encapsulation materials, dielectrics, and insulating materials, providing excellent electrical insulation properties and high-temperature resistance.

6. Paints and Coatings: Spherical alumina powders are widely used in a variety of paints and coatings as functional additives to enhance the hardness, abrasion, and corrosion resistance of coatings.

7. Paints and inks: Due to its excellent dispersibility and flowability, spherical alumina powder is used as fillers and pigments in paints, inks, and printing inks to improve the color stability and coverage properties of the products.

8. Cosmetics: In cosmetics and personal care products, spherical alumina powders are used as fillers and oil absorbents to help enhance texture and oil absorption.

Spherical Alumina Powder (Mixed) Packaging

Our Spherical Alumina Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Spherical Alumina Powder (Mixed) FAQs

Q1: How does spherical alumina powder improve thermal conductivity in materials?

A: The high thermal conductivity of alumina helps dissipate heat effectively. Its spherical shape ensures uniform distribution and minimizes voids in composite materials, leading to enhanced thermal management.

Q2: How is spherical alumina powder produced?

A: It is typically produced through methods such as spray drying, flame synthesis, or plasma processing. These methods help achieve the desired spherical shape and high purity.

Q3: What particle sizes are available for spherical alumina powder?

A: Spherical alumina powder is available in various particle sizes, ranging from nanometers to micrometers, depending on the specific application requirements.