Ready to Press Alumina Description:

Ready to Press Alumina (RTP Alumina) is a high-purity, fine-powder form of aluminum oxide (Al2O3) that is engineered for ease of use in pressing and forming applications. Characterized by its high alumina content, often exceeding 99.5%, RTP Alumina offers minimal impurities, ensuring high material quality. Its controlled particle size distribution enhances flowability and ensures uniform compaction, resulting in consistent green body density and superior sintered properties. Designed for excellent compaction, RTP Alumina allows for the formation of high-density green bodies with minimal effort, leading to components with high mechanical strength and structural integrity. Additionally, its fine particle size and high purity promote efficient sintering at lower temperatures, producing dense, homogeneous ceramic bodies with outstanding mechanical and thermal properties. Consistency and uniformity in manufacturing provide reliable properties batch after batch, making RTP Alumina ideal for demanding applications such as wear-resistant components, cutting tools, and structural ceramics. Its excellent thermal stability enables it to withstand high temperatures, making it suitable for refractory materials and furnace components. Furthermore, RTP Alumina's chemical inertness and resistance to most acids and alkalis make it perfect for use in chemically aggressive environments, ensuring high chemical durability. These properties make RTP Alumina a preferred choice for high-performance ceramic components in industries such as electronics, automotive, aerospace, and industrial manufacturing.

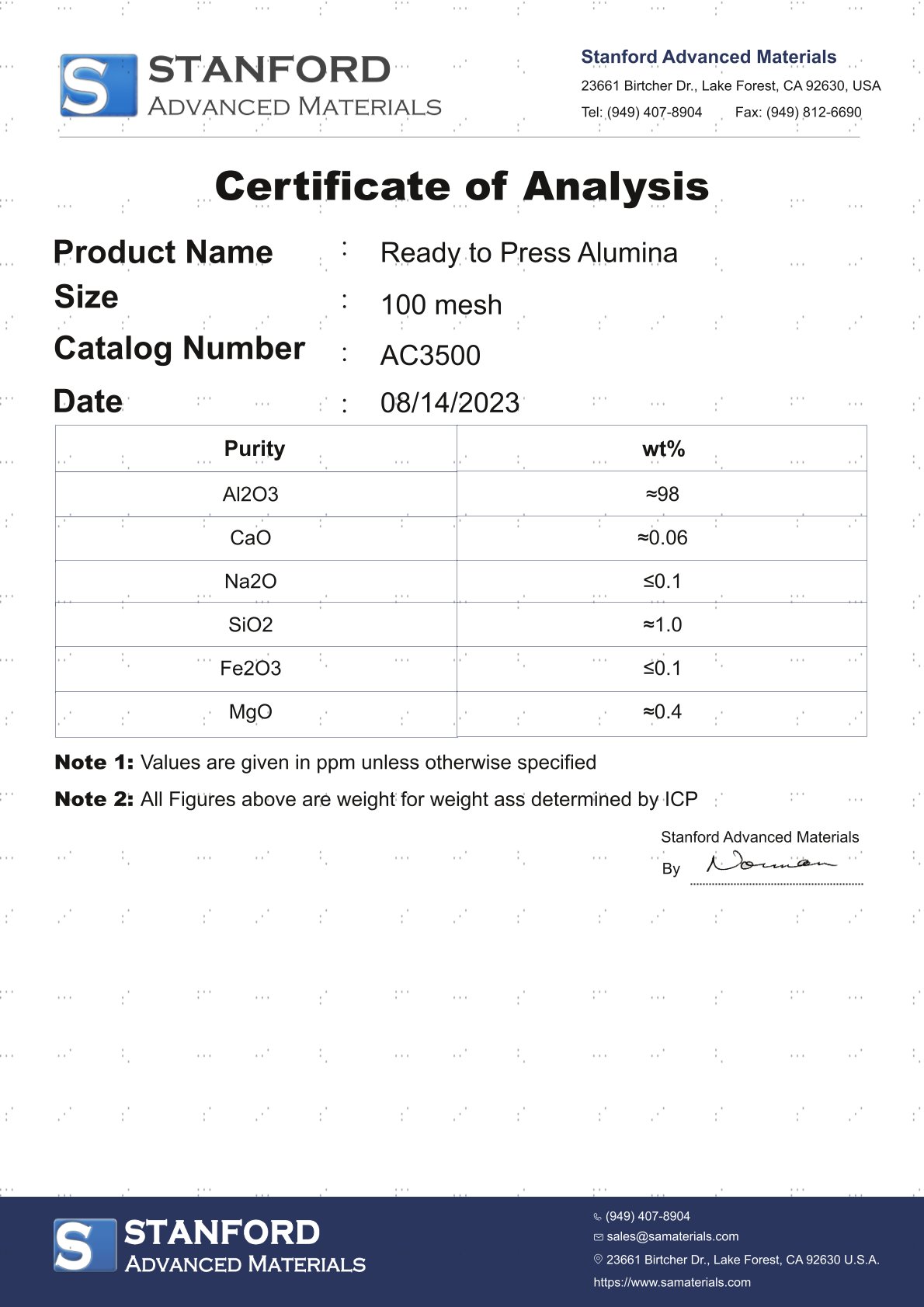

Ready to Press Alumina Specifications:

|

|

KMS-98

|

KMS-96

|

KMS-94

|

KMS-92

|

|

Al2O3 (%)

|

≈98

|

≈96

|

≈94

|

≈92

|

|

CaO (%)

|

≈0.06

|

≈1.3

|

≈0.3

|

≈2.5

|

|

Na2O (%)

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

|

SiO2 (%)

|

≈1.0

|

≈1.9

|

≈4

|

≈3.6

|

|

Fe2O3(%)

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.2

|

|

MgO

|

≈0.4

|

≈0.7

|

≈1

|

≈1.5

|

|

Loss on Ignition (%)

|

≈3

|

≈3.6

|

≈3.0

|

≈4.3

|

|

Bulk Density (kg/m3)

|

≈1200

|

≈1200

|

≈1200

|

≈1100

|

|

Moisture (%)

|

≤0.35

|

≤0.3

|

≤0.35

|

≤0.5

|

|

Median Granule Size (µm)

|

≈130

|

≈170

|

≈100

|

≈200

|

|

Green Density (100 MPa) g/cm3

|

≈2.45

|

≈2.4

|

≈2.4

|

≈2.45

|

|

Fired Density (1600oC, 2h) g/cm3

|

≈3.88

|

≈3.8

|

≈3.7

|

≈3.7

|

Ready to Press Alumina Applications:

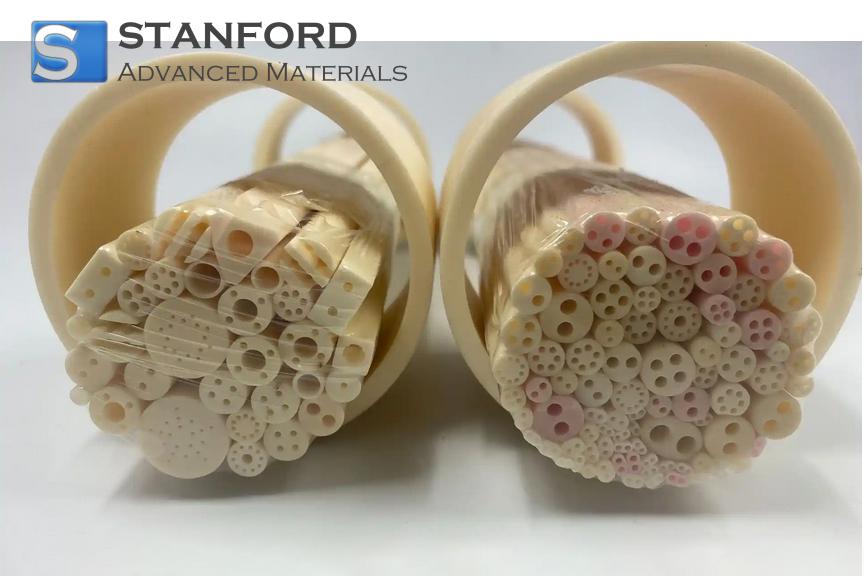

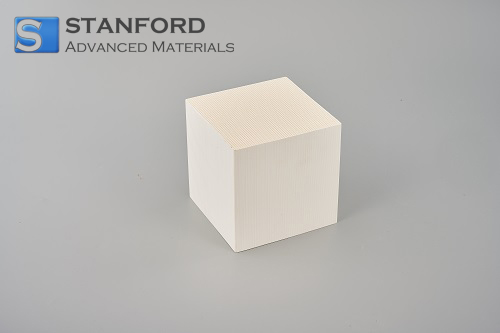

1. Advanced Ceramics: RTP Alumina is used in the production of advanced ceramic components, including structural ceramics, electronic ceramics, and wear-resistant parts. Its properties ensure high mechanical strength and durability.

2. Refractories: It is employed in the manufacture of refractory materials that can withstand high temperatures and harsh environments, making it suitable for furnaces, kilns, and other high-temperature processing equipment.

3. Electronics: RTP Alumina is used to produce electronic components such as insulators, substrates, and dielectric materials due to its excellent electrical insulation properties and thermal conductivity.

4. Automotive Industry: It is used in the production of various automotive components, including spark plugs, sensors, and catalyst supports, thanks to its high thermal stability and chemical inertness.

5. Aerospace: In the aerospace industry, RTP Alumina is utilized for making components that require high strength and thermal resistance, such as engine parts and thermal barrier coatings.

6. Cutting Tools and Abrasives: Its hardness and fine particle size make RTP Alumina an ideal material for cutting tools and abrasive applications, providing high wear resistance and precision.

7. Medical Devices: RTP Alumina is used in the biomedical field for manufacturing bioceramics and medical devices that require high purity and biocompatibility, such as prosthetic implants and dental materials.

8. Industrial Manufacturing: It is used in the production of various industrial components and machinery parts that need high mechanical strength, wear resistance, and thermal stability.

9. Chemical Processing: RTP Alumina is employed as a catalyst and catalyst support in chemical reactions, especially in the petrochemical and environmental industries, due to its high surface area and chemical inertness.

Ready to Press Alumina Packaging:

Our Ready to Press Alumina is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Frequently Asked Questions (FAQ)

- Can Ready to Press Alumina Powder be customized for specific applications?

Yes, Ready to Press Alumina Powder can be customized in terms of particle size, surface area, morphology, and chemical composition to meet the specific requirements of different applications.

- How do you handle and store Ready to Press Alumina Powder?

Handle Ready to Press Alumina Powder with care to prevent contamination and minimize exposure to moisture and air. Store it in a dry and tightly sealed container away from direct sunlight and extreme temperatures.