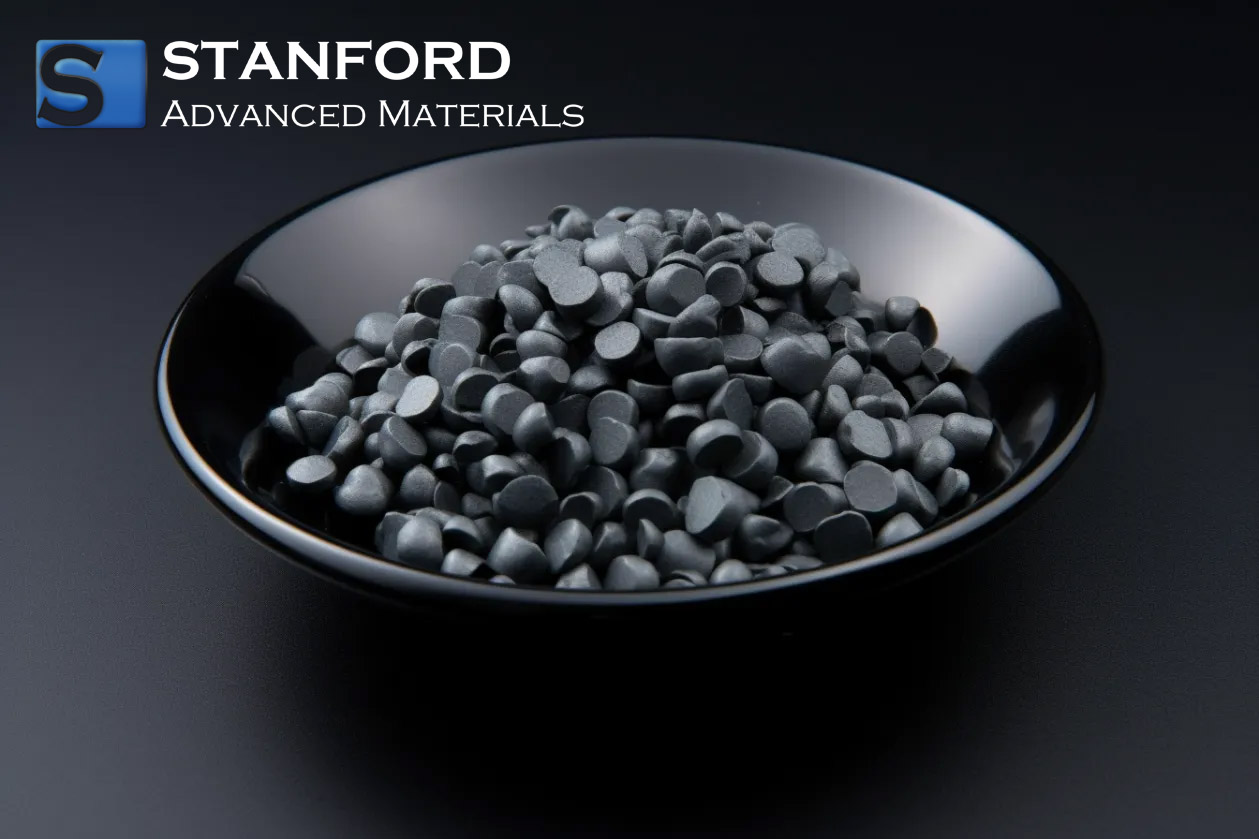

Molybdenum Selenide Evaporation Materials Description

Stanford Advanced Materials (SAM) specializes in producing high purity Molybdenum Selenide Evaporation Materials with high quality for use in semiconductor, chemical vapor deposition (CVD) and physical vapor deposition (PVD) display and optical applications. The unique synergy between our engineering, manufacturing and analytical teams has allowed us to produce industry-leading evaporation materials.

Molybdenum Selenide Evaporation Materials Specification

| Compound Formula |

MoSe2 |

| Appearance |

Solid |

| Melting Point |

>1200 °C |

| Density |

6 g/cm3 |

Molybdenum Selenide Evaporation Materials Application

Molybdenum Selenide (MoSe₂) Evaporation Materials exhibit versatile properties that find applications across multiple technological domains. These include electronics, where MoSe₂ is utilized in field-effect transistors (FETs) and photodetectors due to its high carrier mobility and light-detection capabilities. In energy storage and conversion, MoSe₂ catalyzes the hydrogen evolution reaction (HER) in electrolysis cells and shows promise in lithium-ion batteries. Additionally, MoSe₂ is explored in photovoltaics, catalysis for water splitting, and environmental remediation due to its photocatalytic properties. In coatings and lubricants, MoSe₂ offers corrosion resistance and solid lubrication properties. Furthermore, its applications extend to gas sensors, biomedical devices, and light-emitting devices, contributing to environmental monitoring, healthcare, and optoelectronics advancements. Overall, Molybdenum Selenide Evaporation Materials are crucial in driving innovation across various technological fields by leveraging their unique electronic, optical, and mechanical characteristics.

Molybdenum Selenide Evaporation Materials Packaging

Our Molybdenum Selenide Evaporation Materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.