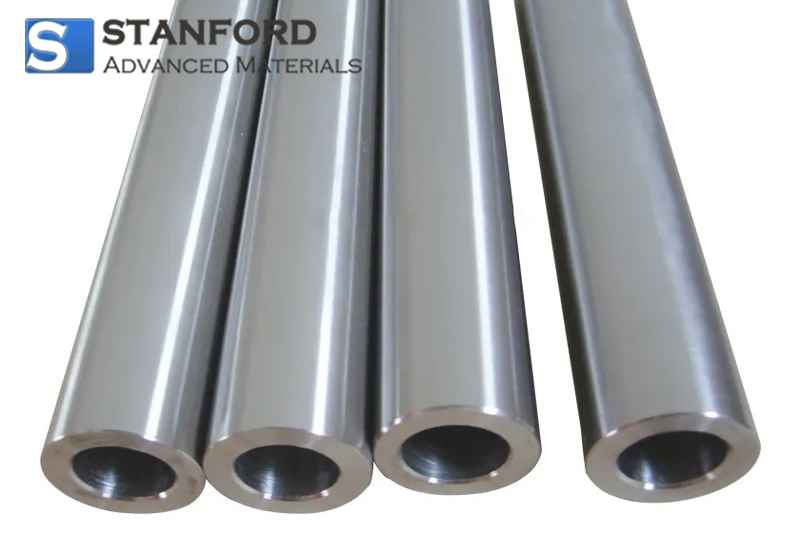

Molybdenum Titanium Evaporation Materials Description

Stanford Advanced Materials (SAM) specializes in producing high purity Molybdenum Titanium Evaporation Materials with high quality for use in semiconductor, chemical vapor deposition (CVD), and physical vapor deposition (PVD) display and optical applications. The unique synergy between our engineering, manufacturing and analytical teams has allowed us to produce industry-leading evaporation materials.

Molybdenum Titanium Evaporation Materials Specification

|

Materials

|

Molybdenum Titanium

|

|

Density

|

4.506-10.28g/cm3

|

|

Melting Point

|

1668-2617℃

|

|

Thermal Conductivity

|

21.9-138 W/m·K

|

|

Electrical Conductivity

|

3.02-19.6×10^4 S/m

|

|

Purity

|

99.9%

|

Molybdenum Titanium Evaporation Materials Applications

1. Optical Coatings: Molybdenum Titanium Evaporation Materials are used to prepare optical coatings such as mirrors, optical filters, and anti-reflective coatings. These coatings have important applications in lasers, optical devices, and optical instruments to improve optical performance and increase the durability of optical components.

2. Electronic components: Molybdenum-titanium alloy films have a wide range of applications in the electronics industry. They can be used as metallization layers to manufacture integrated circuits (ICs), solar cells, photodetectors, and other electronic components in the metallization layer, connecting wires, and conductive layers.

3. Thermal Control Coatings: Due to the high thermal stability of titanium, Molybdenum Titanium Evaporation Materials can also be used to prepare thermal control coatings for high-temperature environments, such as coatings in aerospace engines, turbines, and gas turbine engines.

4. Ceramic Coatings: Molybdenum Titanium thin films can also be used to prepare ceramic coatings to improve the wear resistance, corrosion resistance, and thermal stability of ceramic materials for automotive engine components, cutting tools, and other applications.

5. Optical Fiber Coatings: Molybdenum Titanium Evaporation Materials can also be used to prepare optical fiber coatings to improve the transmission performance and durability of optical fibers, which are widely used in the fields of communications, medical, and sensors.

Molybdenum Titanium Evaporation Materials Packaging

Our Molybdenum Titanium Evaporation Materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

Titanium (Ti) General Information

Titanium is a common material found in a myriad of products including watches, drill bits, laptops, and bicycles, just to name a few. In pure form, it is lustrous and silvery-white in appearance. It has a melting point of 1,660°C, a density of 4.5 g/cc, and vapor pressure of 10-4 Torr at 1,453°C. It is a sturdy material that is easily fabricated when heat is applied. Its strong, lightweight characteristics and excellent corrosion resistance make it ideal for ocean liner hulls, aircraft engines, and designer jewelry. Titanium is biocompatible so it can be found in surgical tools and implants. Titanium is generally evaporated in a vacuum for the purposes of wear and decorative, semiconductor, and optical coatings.

Molybdenum (Mo) General Information

Molybdenum is categorized as a transition metal on the Periodic Table. It is metallic grey in appearance with a melting point of 2,617°C, a density of 10.2 g/cc, and vapor pressure of 10-4 Torr at 2,117°C. Due to its strength and high melting point, molybdenum is primarily alloyed with other metals to make corrosion-resistant materials and can be found in tools, aircraft parts, and electrical contacts. Molybdenum is evaporated under vacuum to make advanced displays, semiconductors, and sensors.

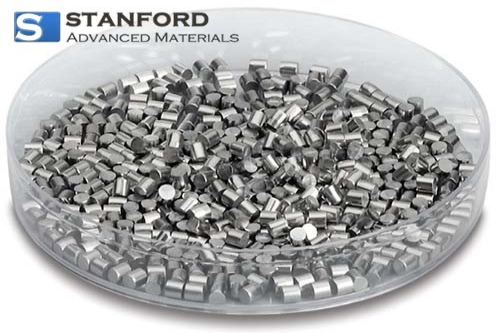

Molybdenum Titanium Pellets Overview

We sell these pellets and pieces by unit weight for evaporation use in deposition processes. These approximate materials prices are published to provide budgetary guidelines. Actual prices can vary and may be higher or lower, as determined by availability and market fluctuations.