Molded Carbon-Graphite Tube, Antimony Description

Molded Carbon-Graphite Tube (Antimony) is a superior mechanical strength carbon-graphite blank, antimony impregnated. It features excellent hardness and good wear resistance.

Molded Carbon features good electrical conductivity, high-temperature resistance, corrosion resistance, high purity, self-lubrication, thermal shock resistance, and easy precision machining.

Babbit impregnation focuses on low friction and self-lubrication, Antimony impregnation enhances hardness and wear resistance, and Resin impregnation improves resistance to oxidation and mechanical strength. The choice of material depends on the specific requirements of the application, such as temperature, wear resistance, and lubrication needs.

Molded Carbon-Graphite Tube, Antimony Specifications

|

Size

|

Customized

|

|

Method of Manufacturing

|

Compression Molded

|

|

Density (g/cm3)

|

2.25

|

|

Flexural Strength (MPa)

|

93.1

|

|

Compressive Strength (MPa)

|

258.6

|

|

Shore Hardness

|

102

|

|

Thermal Conductivity (W/(m2·K/m)

|

208

|

|

Porosity (%VOL)

|

2.5

|

|

Max. Operating Temperature (℃)

|

399

|

Molded Carbon-Graphite Tube, Antimony Applications

Molded Carbon-Graphite Tube (Antimony) is widely used to manufacture Bushings & bearings, Mechanical seals, Thrust washers, Valve seats, Vanes & rotors

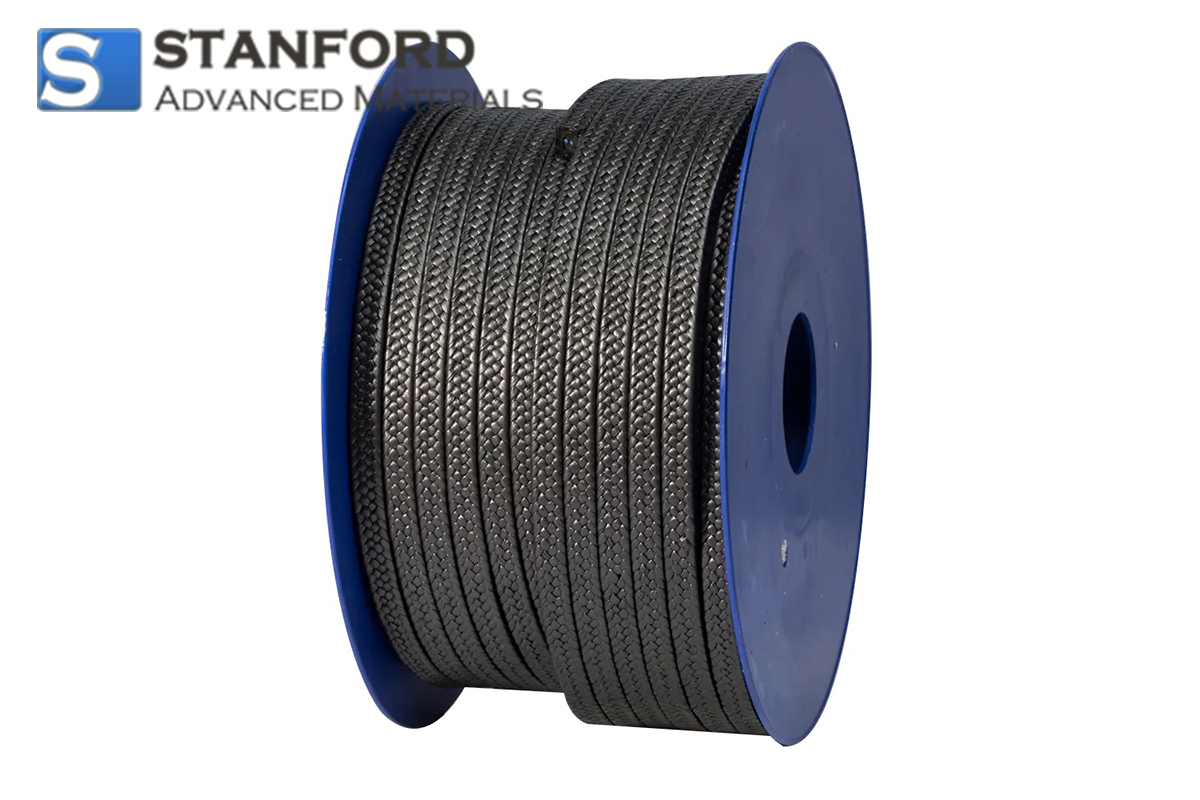

Molded Carbon-Graphite Tube, Antimony Packaging

Our Molded Carbon-Graphite Tube, Antimony is carefully handled during storage and transportation to preserve the quality of our product in its original condition.