GR0188 Graphite Rod (CAS No. 12013-82-0)

| Catalog No. | GR0188 |

| Compositions | Graphite |

| Dimensions | Dia: 50-1200 mm |

| Grain Size | 6-15 μm, 2.0 mm, or customized |

Graphite Rod is mainly used in steel-making furnaces, Mold, Batteries, Alternator Brushes, Metallurgy, Semiconductor Manufacturing, Chemicals, Nuclear Industry. Stanford Advanced Materials (SAM) is a leading supplier of Graphite Rod with competitive pricing and great lead times.

Related products: Graphite Mold, Graphite Electrode for EDM, Graphite Heater

Graphite Rod Description

Graphite Rods are cylindrical structures composed of high-purity graphite, known for their excellent electrical conductivity, thermal conductivity, and chemical stability. These rods exhibit high resistance to thermal shock, and a low coefficient of thermal expansion, and can withstand extreme temperatures without melting or deforming. Graphite rods are also characterized by their lubricating properties, which reduce friction and wear in various applications. They are corrosion-resistant and maintain structural integrity in harsh chemical environments. Due to these properties, graphite rods are widely used in electrochemical processes, high-temperature furnaces, electrical discharge machining (EDM), and as electrodes in arc furnaces.

Stanford Advanced Materials (SAM) offers high-quality graphite rods and carbon rods, essential materials with broad applications across various industries. With excellent properties similar to other graphite products, our rods feature high carbon content, outstanding thermal resistance, and excellent electrical conductivity at high temperatures. These characteristics make them ideal for transportation, energy management, metallurgy, mechanical engineering, chemical processing, and electrochemical industries.

Types of Graphite Rods We Offer:

· Low-Density (LD) Graphite Rods

Composed of coarse-grain graphite with good density and mechanical strength.

Primarily used as a conductive material in mechanical applications.

· High-Density (HD) Graphite Rods

Made from fine-grain graphite, ensuring excellent conductivity and high-temperature resistance.

Ideal for chemical industry applications and specialized high-performance uses.

Graphite Rod Specification

|

Property |

Unit |

LD-1 |

LD-2 |

LD-3 |

LD-4 |

HD-1 |

HD-2 |

HD-3 |

|

Particle Size |

- |

≤2.0 mm |

≤2.0 mm |

≤0.8 mm |

≤0.8 mm |

25-45 μm |

25-45 μm |

25-45 μm |

|

Electrical Resistivity |

μΩ·m |

≤9 |

≤9 |

≤8.5 |

≤8.5 |

≤12 |

≤12 |

10-12 |

|

Bulk Density |

g/cm³ |

≥1.63 |

≥1.71 |

≥1.7 |

≥1.72 |

≥1.78 |

≥1.82 |

1.85-1.90 |

|

Compressive Strength |

MPa |

20 |

28 |

23 |

32 |

60 |

65 |

85-90 |

|

Flexural Strength |

MPa |

≥9.8 |

≥13 |

≥10 |

≥14.5 |

≥30 |

≥35 |

38-45 |

|

Ash Content (Max) |

% / ppm |

0.3% |

0.3% |

0.3% |

0.3% |

250-1000 ppm |

250-1000 ppm |

150-800 ppm |

|

Thermal Expansion Coefficient (100-600°C) (Max) |

×10⁻⁶/°C |

2.5 |

2.5 |

2.5 |

2.5 |

4.5 |

4.5 |

3.5-5.0 |

|

Thermal Conductivity |

W/m·K |

120 |

120 |

120 |

120 |

160-250 |

160-250 |

160-250 |

Graphite Rod Features

*high thermal and chemical resistance

*good thermal conductivity

*low coefficient of thermal expansion

*minimal wettability to molten metals

Graphite Rod Applications

1. Supporting hearth rails or beams: Graphite rods are used to support hearth rails or beams in high-temperature furnaces, accommodating thermal expansion during heating and cooling cycles without deforming, ensuring structural stability.

2. Fixtures or support posts: Graphite rods serve as fixtures or support posts that provide the necessary strength and durability at high temperatures without degrading over extended exposure.

3. Electrodes, stir sticks, and other reaction purposes: Graphite rods are used as electrodes in electrochemical reactions or as high-temperature stir sticks for mixing chemical reagents. Their chemical inertness prevents unwanted reactions with the substances involved.

Graphite Rod Benefits

Machinability to exceptionally close tolerances.

Good Thermal Conductivity as graphite is an excellent heat conductor and has great resistance to thermal shock.

High Compressive Strength ranging from 11K-38K lbs/in²

Corrosion Resistance for all practical purposes and is unaffected by most acids, alkalis, solvents, and similar chemicals.

Seal face flatness due to the high modulus of elasticity and stability to remain flat during operation at the rubbing faces.

Built-in Lubrications and Non-Galling. Products will not seize or gall in the most severe applications as the molecular structure of graphite forms an extremely thin film on moving parts.

Porosity. Graphite can be porous but impregnants are used to fill these pores and can range from high to totally impervious depending on need.

Graphite Rod Packing

Our Graphite Rod is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1. What are the main applications of graphite rods?

Graphite rods are widely used in various industries, including:

Chemical Industry: Used to isolate flames and enhance safety in chemical processing.

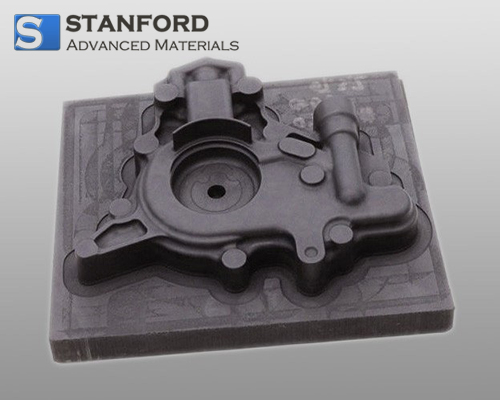

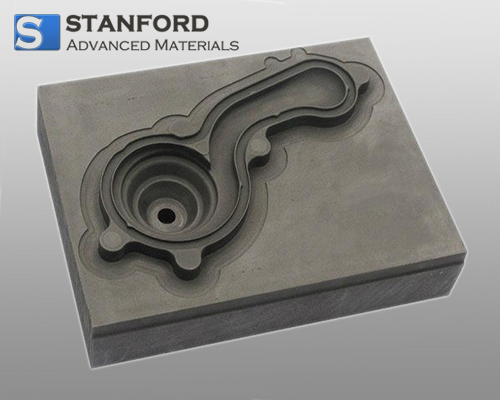

High-Temperature Metallurgy: Serves as casting molds for glass and metal to ensure precise dimensions.

Wear-Resistant Lubrication: Functions as piston cups in corrosive environments and provides lubrication in high-speed, high-temperature mechanical applications.

Refractory Applications: Used as protective liners in steelmaking.

Other Uses: Heating elements in vacuum furnaces, electrical resistors, degassing tubes, graphite crucibles, and more.

Q2. What should be considered when using graphite rods in high-temperature furnaces?

- Electrical Load: The higher the applied current, the higher the surface temperature. It is recommended to use the lowest possible surface power density.

- Parallel Connection: Graphite rods should be connected in parallel to balance the load and prevent premature failure.

- Oxidation Protection: When heated in air, graphite rods form a silicon oxide film, which provides oxidation resistance. Additional coatings can be applied for enhanced protection in specialized environments.

- Temperature Distribution: Initially, the temperature distribution should be within ±60°C, but it may increase up to 200°C over time.

- Prolonging Lifespan: Gradually increasing resistance helps extend the service life.

- Operating Temperature: When furnace temperatures exceed 1400°C, oxidation accelerates, leading to shorter lifespans. It is essential to avoid excessive surface temperatures.

Q3. How does oxidation affect the lifespan of graphite rods?

The oxidation of graphite rods increases over time and at higher temperatures, leading to gradual material loss. Regular maintenance and controlled atmospheric conditions can help slow down oxidation and prolong the service life of the rods.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!