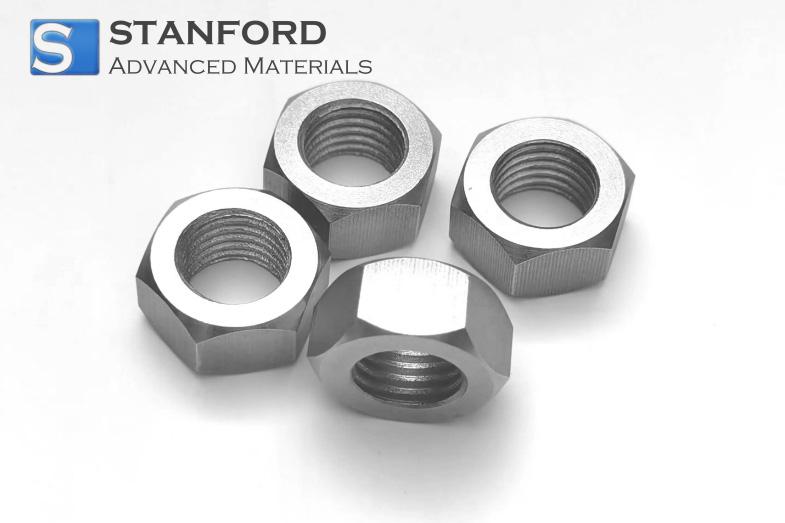

Molybdenum Fastener Description

Our Molybdenum Fasteners, including screws, nuts, and bolts, are crafted from pure molybdenum (Mo ≥ 99.95%) to ensure outstanding durability and performance in demanding environments. Molybdenum is renowned for its high melting point (approximately 3,200°C) and exceptional corrosion, oxidation, and wear resistance, making it ideal for high-temperature applications such as aerospace, electronics, and industrial processes. These fasteners can be custom-sized according to customer specifications, with screws starting from M2 in diameter. The surface finish is turning, ensuring smooth and precise components. Our fasteners meet the ASTM B387 standard, guaranteeing consistent quality and reliability.

Properties:

1. High melting point: Molybdenum has a very high melting point, which allows Molybdenum Fasteners to maintain structural strength and stability in high-temperature environments.

2. High strength: Molybdenum has excellent strength, which allows molybdenum fasteners to perform well under critical loads and stresses.

3. Corrosion Resistance: Molybdenum's high resistance to corrosion allows molybdenum fasteners to maintain long durability in corrosive environments.

4. High Temperature Resistance: Due to its high melting point and thermal stability, molybdenum fasteners are suitable for use in high-temperature work environments, such as aerospace and oil refining.

5. Chemical Stability: Molybdenum exhibits stability in many chemicals, which allows molybdenum fasteners to be used in the chemical industry and specific manufacturing processes.

Molybdenum Fastener Specification

SAM offers a variety of Molybdenum Fasteners, available as Molybdenum Screws, Molybdenum Nuts, and Molybdenum Bolts.

Molybdenum Threaded Rod

Molybdenum threaded rods can withstand high temperatures and vacuum thermal evaporation. They can be cut down to various sizes and combined with washers/nuts to form custom screws.

Molybdenum Screw

Molybdenum screws can withstand high temperatures and vacuum thermal evaporation. SAM supplies these screws using both the ANSI and metric sizes of fillister, pan, and flatheads. We generally produce standard-length screws but can customize lengths based on customer needs.

Molybdenum Nut

Molybdenum refractory nuts can withstand high temperatures and vacuum thermal evaporation. They can be produced in inch or metric sizes and various shapes (hex being the most common).

Molybdenum Washer

Molybdenum refractory washers can withstand high temperatures and vacuum thermal evaporation. They can be produced in inch or metric sizes and various shapes. Their purpose is to distribute the load of thread fasteners.

Molybdenum Fastener Application

1. Aerospace Industry: Due to its high melting point and excellent high-temperature stability, molybdenum fasteners are commonly used in aerospace devices such as engines and other structural components in high-temperature environments.

2. Electronics industry: Molybdenum fasteners are used in a wide range of electronic devices, especially in high-temperature environments, such as in the manufacture and assembly of electronic components.

3. Chemical industry: Due to its corrosion resistance, molybdenum fasteners are commonly used in the chemical industry, especially in corrosive environments, to ensure stability and long life.

4. Nuclear industry: Molybdenum fasteners also play an important role in nuclear energy applications such as nuclear power plants, as molybdenum is highly resistant to radiation.

5. Manufacturing: Molybdenum fasteners are used in production equipment and industrial machinery where high-temperature and corrosion-resistant materials are required for certain manufacturing processes.

Molybdenum Fastener Packaging

Our Molybdenum Fasteners are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

Molybdenum Fastener FAQs

Q1: Can I order custom molybdenum fasteners?

A1: Yes, we offer custom molybdenum fasteners, including screws, nuts, and bolts, in various sizes, thread types, and lengths. If you have specific material, design, or performance requirements, we can create a solution tailored to your needs. Please get in touch with us for more details.

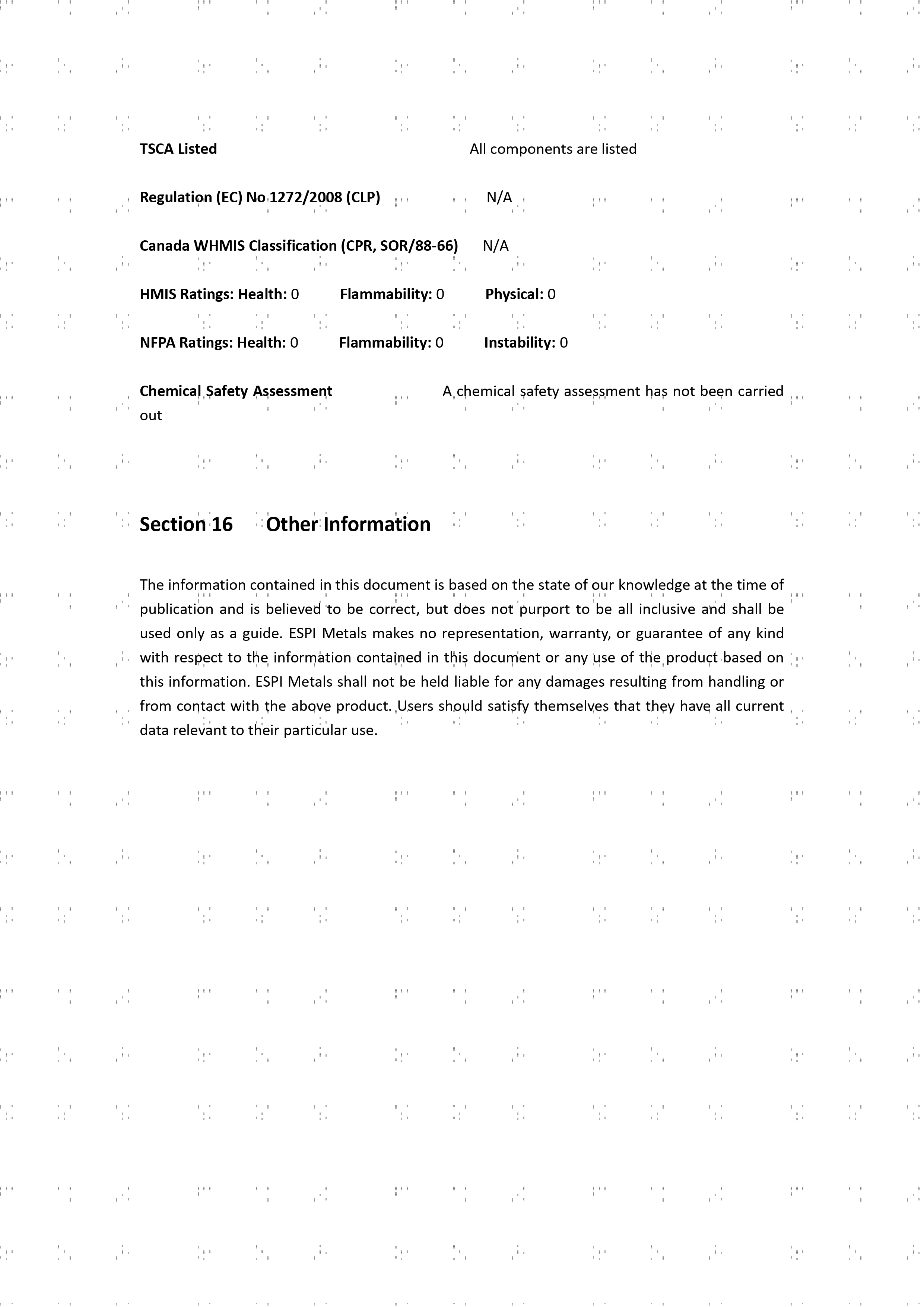

Q2: Do you provide Material Safety Data Sheets (MSDS) or technical support?

A2: Yes, we provide Material Safety Data Sheets (MSDS) and offer comprehensive technical support for molybdenum fasteners. Our team can assist you with product handling, safety guidelines, and technical specifications. Feel free to contact us for more information.

Q3: Are molybdenum fasteners compatible with all chemicals?

A3: Molybdenum fasteners are highly resistant to corrosion and most chemicals, making them suitable for a wide range of chemical applications. However, compatibility with specific chemicals should be verified for certain highly aggressive substances, especially under extreme conditions. Please contact us if you need assistance with material compatibility.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano