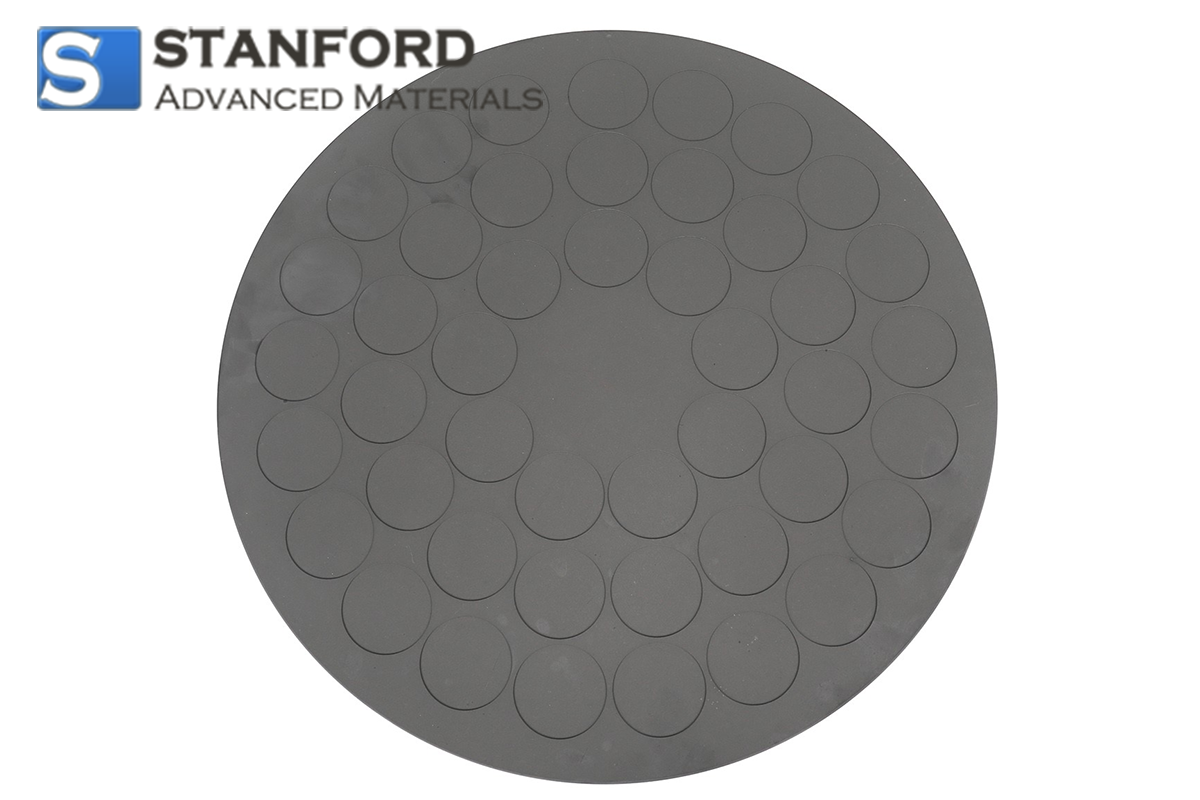

MOCVD Graphite Disc Description

MOCVD (Metal Organic Chemical Vapor Deposition) Graphite Disc is a high-purity graphite component used in MOCVD reactors as a susceptor or wafer carrier. MOCVD Graphite Disc features high-temperature resistance, oxidation resistance, erosion resistance, high purity, acid and alkali salt resistance, and organic reagent resistance. MOCVD is a critical process in the semiconductor industry for depositing very thin layers of material onto substrates, typically used in the manufacturing of LEDs, solar cells, and various types of semiconductor devices.

MOCVD Graphite Disc Specifications

|

Density

|

g/cm3

|

3.15-3.20

|

|

Mohs Hardness

|

-

|

9.5

|

|

Lattice constant

|

nm

|

α 0.434

|

|

Thermal Conductivity

|

w/m·k

|

80

|

|

Thermal expansion rate

|

10-6℃-1

|

4.7

|

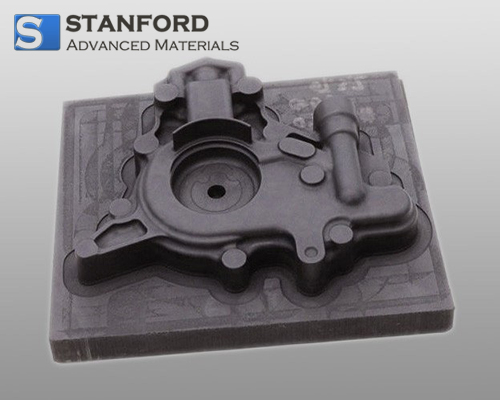

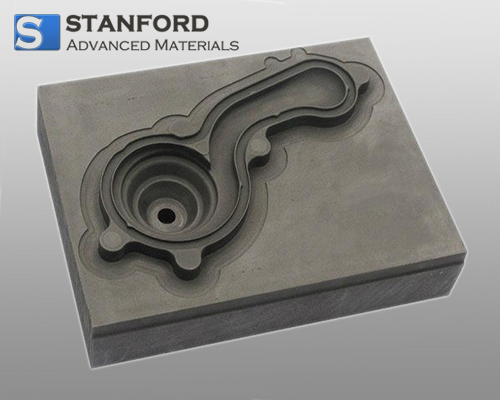

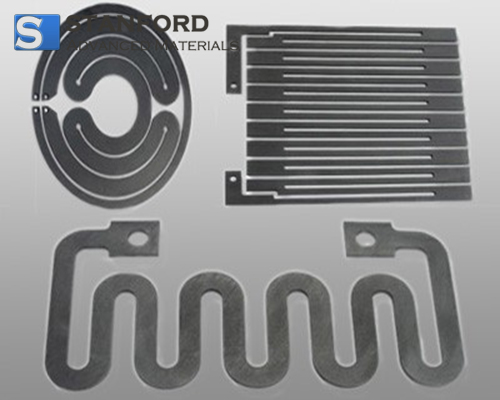

MOCVD Graphite Disc Applications

- Semiconductor Layer Deposition: Graphite discs are used as substrates or wafers carriers in the deposition of various semiconductor layers, such as those used in LEDs, laser diodes, and power electronics.

- Solar Cell Production: In the manufacturing of photovoltaic cells, MOCVD graphite discs are used for depositing thin films that enhance the efficiency of solar cells.

- Advanced Electronics Manufacturing: For devices requiring precise control over material properties, such as smartphones and tablets, MOCVD graphite discs facilitate the deposition of materials with specific electrical, optical, and structural characteristics.

MOCVD Graphite Disc Packaging

Our MOCVD Graphite Disc is carefully handled during storage and transportation to preserve the quality of our product in its original condition.