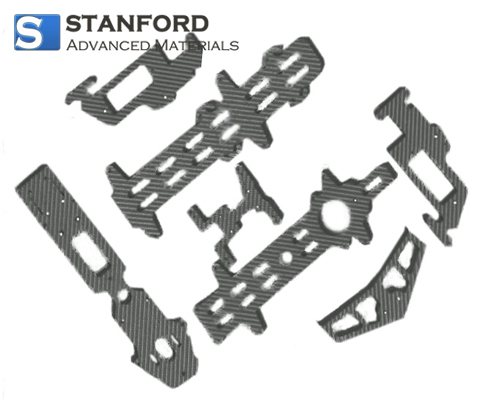

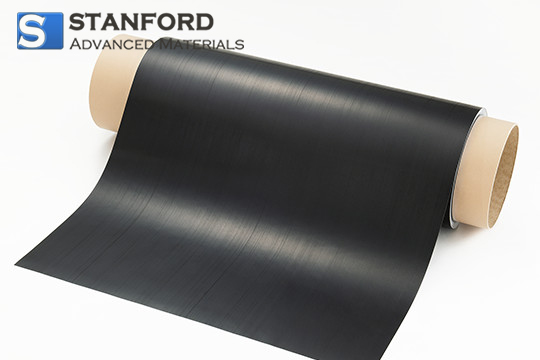

Carbon Fiber Machined Product Description

Carbon Fiber Machined Product is a long and thin strand of fiber composed mostly of carbon atoms. As carbon atoms are bonded together in crystals within the fibers. As the carbon crystals are more or less formed parallel to the long axis of the fibers, the material is extremely strong for its size.

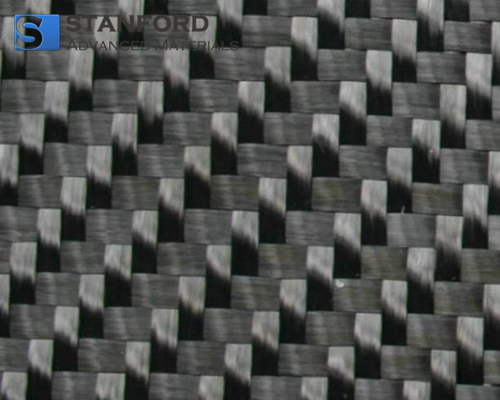

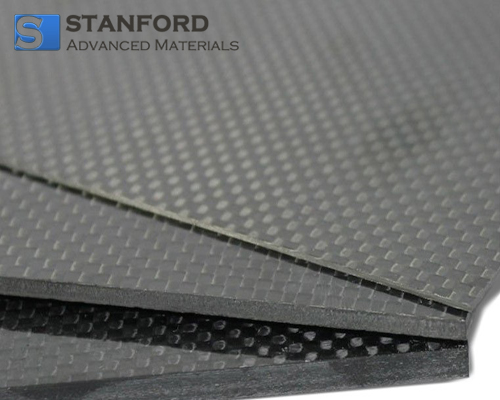

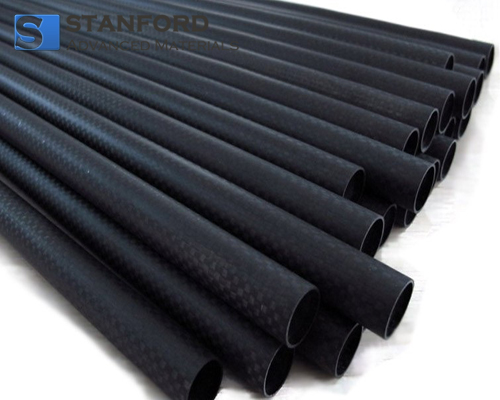

Thousands of carbon fibers, usually 3k~12k for consumer products, are twisted together to form a yarn. These carbon fiber yarns are further fabricated or weave into carbon cloth, which is the foundation of most carbon fiber products that we can find on market. Then, carbon cloth would be combined with epoxy or other polymers and molded into different shapes for various applications. Carbon fiber materials are so strong that even materials made by lower grade carbon fibers, e.g. T300, have great strength if designed and manufactured in a proper way.

Carbon Fiber Machined Product Specification

|

Catalog No.

|

GR0462

|

|

Density

|

1.6 - 2.0 g/cm³

|

|

Tensile Strength

|

3000 - 7000 MPa

|

|

Tensile Modulus

|

200 - 600 GPa

|

|

Coefficient of Thermal Expansion

|

0.5 - 2.0 × 10^-6 /°C

|

|

Thermal Conductivity

|

30 - 120 W/(m·K)

|

|

Conductivity

|

10^2 – 10^6 S/m

|

|

Operating Temperature

|

300 - 350°C

|

Carbon Fiber Machined Product Application

Carbon fiber parts are light weighted, compared with similar components made by metal. Carbon fiber composite materials are used to make high-performance sports equipment, including bicycle frames, fishing rods, automobile body parts, frames for models, and more. High-quality carbon fiber materials are applied in aviation industries to replace traditional alloys.

Carbon Fiber Machined Product Features

As the demand for carbon fiber parts continues to increase, working with carbon fiber machining experts has become exceedingly important. Carbon composites can break unpredictably, resulting in potential unrepairable results if not machined properly. Some benefits of machined carbon fiber parts include:

- Corrosion-resistant

- Non-toxic

- Non-flammable

- X-ray permeable

- Electrically conductive

Carbon Fiber Machined Product Packing

Our Carbon Fiber Machined Products are carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Carbon Fiber Machined Product FAQs

Q1: What industries use Carbon Fiber Machined Products?

A1: Carbon fiber machined products are widely used in various industries due to their strength, lightweight properties, and precision. Some key industries include:

Aerospace: For manufacturing lightweight structural components, brackets, and supports that can withstand high stress and temperatures.

Automotive: For custom components in high-performance vehicles, including body panels, chassis parts, and suspension components, where reducing weight without compromising strength is critical.

Sports Equipment: For precision-engineered parts in bicycles, golf clubs, skis, and other sports equipment that require lightweight and high-performance materials.

Medical Devices: For custom prosthetics, orthotics, and other medical devices that require strength, lightweight properties, and durability.

Electronics: For lightweight, high-strength enclosures or internal components for electronic devices, drones, and robotics.

Robotics: In robotic arms, grippers, and frames, where the need for lightweight, strong, and rigid materials is paramount.

Marine: For custom carbon fiber components like masts, hull reinforcements, and structural parts for boats and yachts.

Q2: What are the benefits of Carbon Fiber Machined Products?

A2: Carbon fiber machined products offer several significant benefits:

High Strength-to-Weight Ratio: Carbon fiber is incredibly strong yet lightweight, making these products ideal for applications where reducing weight while maintaining strength is critical.

Precision and Accuracy: CNC machining allows for high precision and tight tolerances, ensuring that parts fit perfectly and perform optimally in complex assemblies.

Durability: Carbon fiber is resistant to corrosion, wear, and environmental degradation, making it suitable for demanding environments.

Customization: These products can be manufactured to meet specific design, performance, and aesthetic requirements, ensuring that each component is tailored to the exact needs of the application.

Enhanced Performance: Carbon fiber's high stiffness and impact resistance contribute to improved performance in high-stress and high-performance environments.

Q3: How are Carbon Fiber Machined Products manufactured?

A3: The manufacturing process for carbon fiber machined products typically involves:

Material Selection: The appropriate carbon fiber material (sheet, prepreg, or composite) is selected based on the required performance characteristics.

Cutting and Preparation: The carbon fiber material is cut to the desired size or shape using tools such as a laser cutter, water jet, or band saw.

CNC Machining: Using CNC machines, the material is precisely cut, drilled, shaped, and finished to the required specifications. CNC machining provides high precision, making it ideal for complex geometries and tight tolerances.

Finishing: After machining, the product may be finished with processes like sanding, polishing, or coating to achieve the desired surface finish (matte, gloss, etc.).

Quality Control: All products undergo thorough quality control checks to ensure they meet the required specifications, including dimensional checks, strength testing, and surface finish evaluations.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano