Polycrystalline NCA Cathode Material Description

Polycrystalline NCA Cathode Material is suitable for lithium-ion batteries for power tools and EV vehicles.

Polycrystalline NCA Cathode Material Specification

|

Items

|

D50

(µm)

|

Tap

(g/cm3)

|

Specific Area

(m2/g)

|

Capacity

(mAh/g)

|

OH-1

Wt%

|

CO3-2

Wt%

|

Efficiency (%)

|

|

N8-L

|

11.5±2.0

|

≥3.5

|

2.2±0.5

|

≥200

|

≤0.05

|

≤0.25

|

≥87

|

|

N8-B

|

12.5±2.0

|

≥3.5

|

0.5±0.3

|

≥205

|

≤0.1

|

≤025

|

≥87

|

|

M8-C

|

12.5±2.0

|

≥3.5

|

1.5±0.5

|

≥215

|

≤0.2

|

≤0.3

|

≥87

|

Polycrystalline NCA Cathode Material Applications

It is suitable for lithium-ion batteries for power tools and EV vehicles.

Polycrystalline NCA Cathode Material Packaging

Our Polycrystalline NCA Cathode Material is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Polycrystalline NCA Cathode Material FAQs

Q1. What is Polycrystalline NCA Cathode Material?

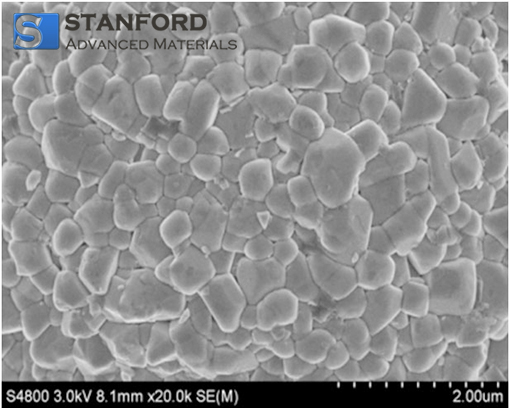

Polycrystalline NCA (Nickel-Cobalt-Aluminum) cathode material is a type of lithium-ion battery cathode made from a combination of nickel, cobalt, and aluminum in a polycrystalline structure. It is known for its high energy density, stability, and performance in rechargeable batteries.

Q2. How is Polycrystalline NCA Cathode Material produced?

It is typically produced through a co-precipitation method where nickel, cobalt, and aluminum salts are mixed and precipitated to form a precursor. This precursor is then calcined at high temperatures to create the final polycrystalline NCA structure.

Q3. Can Polycrystalline NCA Cathode Material be recycled?

Yes, polycrystalline NCA cathode material can be recycled. Recycling processes typically recover valuable metals like nickel, cobalt, and aluminum from used batteries, which can then be reused in new cathode materials.