- Products

- Categories

- Blog

- Podcast

- Application

- Document

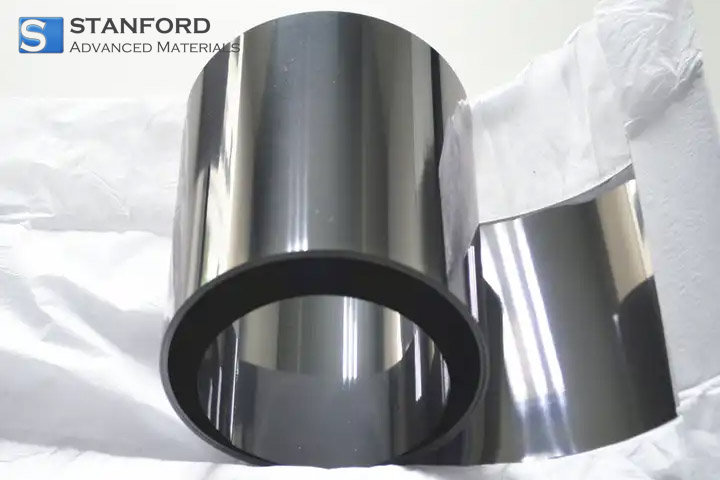

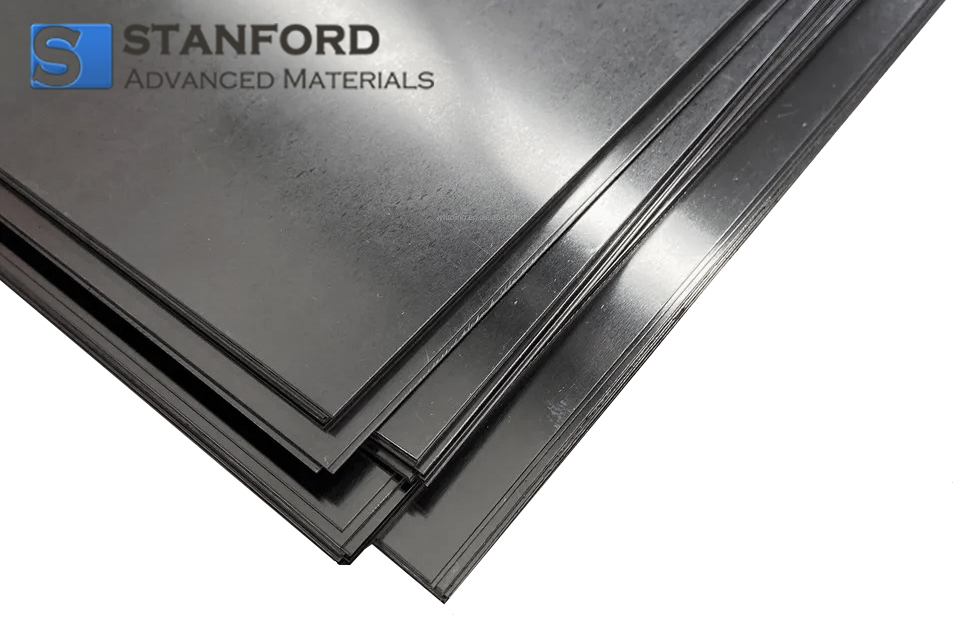

MU1420 Molybdenum Foil (Mo Foils)

| Catalog No. | MU1420 |

| Size | 0.1-1 mm x 50-500mm x L |

| Material | Mo≥99.95% & TZM |

| Standard | ASTM B386 |

| Density | 9.8 - 10.2 g/cc |

| Surface | Cold Rolling |

Molybdenum Foil (Mo Foil) is often used for heat and x-ray shielding, production of drawn parts, electronic components, and metalizing sources. Stanford Advanced Materials provides a wide range of molybdenum foil and other Mo metal products with competitive prices and great delivery times. Customized forms are available upon request.

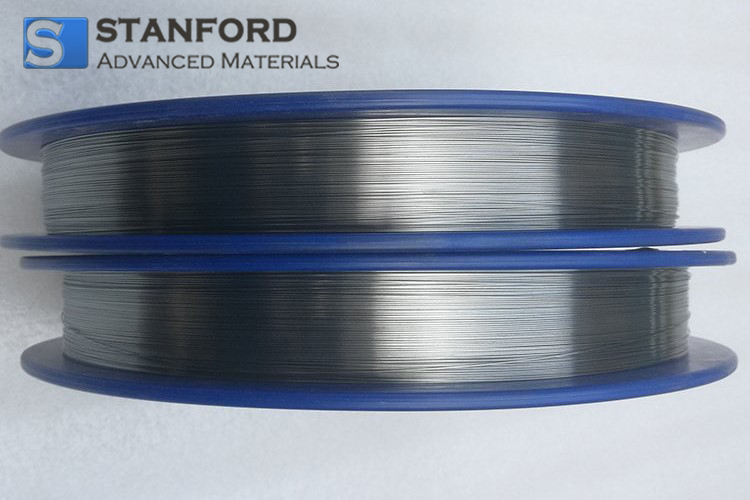

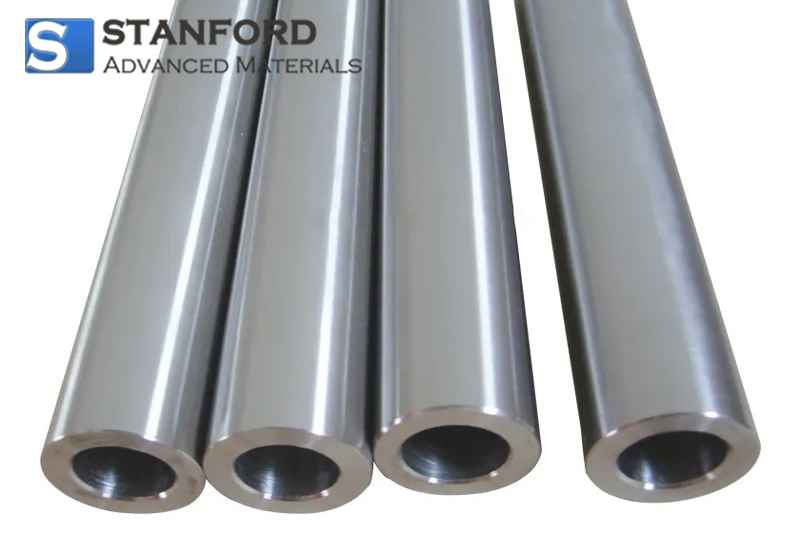

Related Products: Molybdenum Disc, Molybdenum Plate, Molybdenum Strip.

Molybdenum Foil Description

Molybdenum is a gray metal and has a very high melting point. It is found in various oxidation states in minerals but does not occur naturally as a free metal. Molybdenum allows readily to form hard and stable carbides. For this reason, molybdenum is frequently used for making steel alloys, high-strength alloys, and superalloys. Molybdenum foil is one of the molybdenum products and is widely used in electronics, aviation, aerospace, electric light sources, heating elements in vacuum furnaces, heat shields, and molybdenum boats, and molybdenum crucibles.

Properties:

1. High melting point: Molybdenum has a very high melting point of approximately 2,623 ℃. This allows Molybdenum Foil to maintain its structure and properties at extreme temperatures.

2. High density: Molybdenum is a dense metal with a density of approximately 10.28 g/cm3. This high density gives Molybdenum Foils a high degree of quality and stability in many applications.

3. Good thermal conductivity: Molybdenum has good thermal conductivity, which makes Molybdenum Foil very effective in some applications where heat dissipation is required. It can transfer and dissipate heat quickly.

4. Good mechanical properties: Molybdenum Foil retains its mechanical strength and flexibility in film form, which makes it suitable for applications that require bending or deformation.

5. Corrosion resistance: Molybdenum Foils show good resistance to many chemicals, which increases their potential for use in special environments.

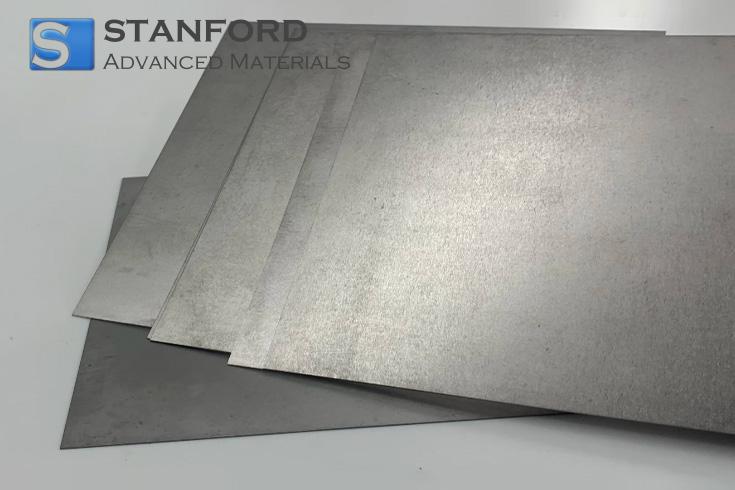

Molybdenum Foil Specifications

|

Material |

Purity |

|

Molybdenum Foil .001” |

> 99.95% |

|

Molybdenum Foil .002” |

> 99.95% |

|

Molybdenum Foil .003” |

> 99.95% |

|

Molybdenum Foil .004” |

> 99.95% |

|

Molybdenum Foil .005” |

> 99.95% |

|

Molybdenum Foil .006” |

> 99.95% |

|

Molybdenum Foil .007” |

> 99.95% |

|

Molybdenum Foil .008” |

> 99.95% |

|

Molybdenum Foil .009” |

> 99.95% |

Apart from standard sizes, tailor-made dimensions are also available.

Molybdenum Foil Applications

1. Semiconductor industry: Molybdenum Foils are commonly used in the thin film deposition process in semiconductor manufacturing for the preparation of thin film components such as metal oxide semiconductor field effect transistors (MOSFETs).

2. Electronics: Due to its high melting point and thermal conductivity, Molybdenum Foil is used as a heat sink in many electronic devices and helps to maintain device performance at high temperatures.

3. Laboratory research: Molybdenum Foils are used in laboratories for a variety of research and experimental purposes, including optical research, thin-film experiments, and other experiments that require high temperatures and high-density materials.

4. Vacuum equipment: Due to its high melting point and corrosion resistance, Molybdenum Foil has applications in the manufacture of vacuum equipment and vacuum fittings, ensuring the stability of the equipment at high temperatures and under vacuum conditions.

5. Thermal barrier coatings: Molybdenum Foils are sometimes used to prepare thermal barrier coatings for high-temperature environments, providing thermal insulation against high temperatures.

Molybdenum Foil Packaging

Our Molybdenum foils are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Molybdenum Foil FAQs

Q1: How is Molybdenum Foil produced?

A1: Molybdenum foil is produced by rolling molybdenum metal into thin sheets. The process involves heating the molybdenum in a controlled environment to a temperature where it becomes malleable and can be rolled into thin foils. These foils are then cooled, annealed, and cut to the required thickness and dimensions.

Q2: Is Molybdenum Foil flexible and easy to work with?

A2: Yes, Molybdenum foil is flexible and can be easily manipulated into different shapes, which makes it suitable for a variety of applications. It can be cut, bent, or formed into custom configurations for specific needs. However, due to its high melting point and strength, it is best processed using specialized equipment.

Q3: Can Molybdenum Foil be used in high-temperature environments?

A3: Yes, Molybdenum foil is specifically designed for high-temperature environments. Its high melting point (over 3,100°C) and excellent thermal stability make it an ideal material for applications in furnaces, reactors, and other high-heat conditions. It is commonly used in aerospace, semiconductor manufacturing, and other industries where heat resistance is critical.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!