Machinability Rating Charts

What Is Machinability

Machinability refers to the ease with which a material can be cut, shaped, or finished using machining processes. It affects tool life, surface finish, and production speed. High machinability materials require less force and result in a longer tool lifespan.

Factors Affecting Machinability

Several factors influence a material's machinability, including:

- Material Properties: Hardness, toughness, and thermal conductivity.

- Tooling: Cutting tool materials and geometry.

- Machining Conditions: Speed, feed rate, and cooling methods.

- Surface Finish Requirements: Desired level of smoothness.

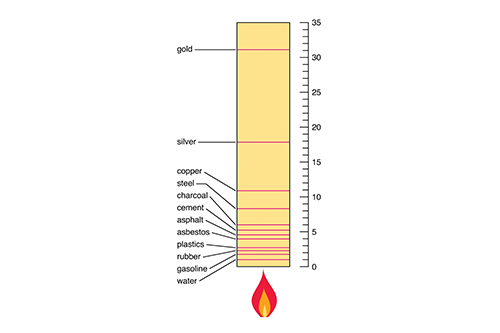

Machinability Rating Charts

A machinability rating table is commonly used to assess how easily a material can be machined. It considers various factors such as hardness, toughness, and the material’s response to cutting forces, temperature, and wear. The machinability rating is typically compared to a reference material, which is often free-cutting steel, assigned a rating of 100. Materials with higher ratings are easier to machine, while those with lower ratings are more challenging.

Below is a typical machinability rating table:

|

Material |

Machinability Rating |

Comments |

|

Free-Cutting Steel (12L14) |

100 |

Excellent machinability, often used as a baseline. |

|

Carbon Steel (1018) |

80 |

Fairly easy to machine, common in industrial applications. |

|

90 |

Good machinability, soft and easy to machine. |

|

|

35 |

Poor machinability due to toughness and work hardening. |

|

|

20 |

Low machinability, prone to heat buildup and tool wear. |

|

|

Cast Iron |

70 |

Good machinability, though can cause tool wear due to graphite. |

|

10 |

Very poor machinability, requires specialized tools. |

|

|

Nickel (Inconel 625) |

18 |

Difficult to machine, hard and tough at high temperatures. |

|

Copper |

85 |

Easy to machine, but can cause high tool wear due to its softness. |

|

Brass (C36000) |

120 |

Excellent machinability, often used in precision parts. |

|

Magnesium |

95 |

Good machinability, light and easy to machine. |

|

45 |

Poor machinability, requires special care due to brittleness. |

|

|

Leaded Steel (11L17) |

110 |

Excellent machinability, used in applications where ease of machining is crucial. |

|

Hastelloy C-276 |

15 |

Very difficult to machine, requires special tools and techniques. |

This table provides general ratings, but actual machinability can vary based on the machining process (e.g., turning, milling, drilling), tool type, and specific material grades.

Frequently Asked Questions

What does a higher machinability rating indicate?

A higher machinability rating means the material is easier to machine, resulting in faster production and longer tool life.

How are machinability ratings determined?

They are determined based on factors like tool wear, surface finish, and machining speed during standardized tests.

Why is aluminum often preferred for machining?

Aluminum has high machinability, low density, and good thermal conductivity, making it ideal for various manufacturing processes.

Can machinability affect the cost of production?

Yes, materials with higher machinability can reduce production time and tool wear, lowering overall manufacturing costs.

Are machinability ratings the same for all machining processes?

No, different processes like turning, milling, and drilling may have varying effects on a material's machinability.