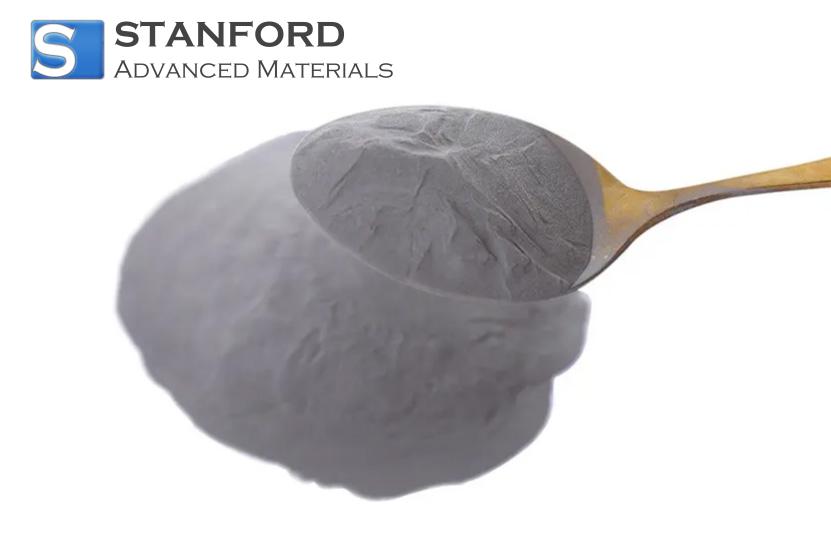

Copper Manganese Alloy Powder Description

Copper Manganese Alloy Powder is a finely engineered material composed of copper (Cu) and manganese (Mn) elements, offering enhanced properties for a wide range of industrial applications. This alloy powder is typically produced through atomization or other advanced processes to ensure high purity, uniform particle size, and consistent quality. The addition of manganese to copper improves the alloy’s strength, wear resistance, and corrosion resistance, making it ideal for harsh environments. While not as conductive as pure copper, the alloy maintains a balanced conductivity, which is suitable for various electrical and electronic components. Copper manganese alloy powder exhibits stable thermal conductivity, making it suitable for applications requiring controlled heat dissipation.

Copper Manganese Alloy Powder Specifications

|

Wt%

|

Cu/Mn: 85/15, 72/25, or customized

|

|

Particle Size

|

0.5-250μm, or customized

|

|

Shape

|

Spherical

|

|

Density

|

~7.6g/cm3

|

|

Electrical Resistivity

|

200-250 µΩ·cm

|

|

Melting Point

|

860-1020℃

|

Copper Manganese Alloy Powder Applications

- Battery Materials: Used in the production of electrodes and anodes for high-performance batteries.

- Electrical Contacts: Ideal for making electrical connectors, switches, and relays due to its good conductivity and strength.

- Alloy Synthesis: Used as an intermediate material for producing other advanced alloys.

- Coatings and Surface Treatments: Provides wear resistance and corrosion protection in mechanical and automotive industries.

- Additive Manufacturing: The fine powder form is suitable for 3D printing and additive manufacturing processes, allowing for the creation of complex metal components.

Copper Manganese Alloy Powder Packing

Our Copper Manganese Alloy Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1: What are the benefits of using Copper Manganese Spherical Alloy Powder?

- Improved flowability: The spherical shape allows for better powder flow during additive manufacturing and other powder processing techniques.

- Enhanced mechanical properties: The alloy offers a balance of strength, corrosion resistance, and wear resistance, especially compared to pure copper.

- Good electrical conductivity: While not as high as pure copper, it retains sufficient conductivity for most electronic applications.

- Corrosion and oxidation resistance: The addition of manganese helps prevent degradation in aggressive environments, extending the lifespan of components.

Q2: Can Copper Manganese Spherical Alloy Powder be used in 3D printing?

Yes, its spherical shape and fine particle size make Copper Manganese Spherical Alloy Powder ideal for use in metal 3D printing technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). Its uniform size and excellent flow properties enable precise, high-quality printing of complex parts.

Q3: How should Copper Manganese Spherical Alloy Powder be stored?

The powder should be stored in a cool, dry place, away from moisture and direct sunlight, to prevent any oxidation or degradation. Containers should be tightly sealed to prevent contamination or moisture absorption.

Powder.jpg)