TA1322 Spherical Tantalum Powder (Ta)

| Catalog No. | TA1322 |

| Color | Black |

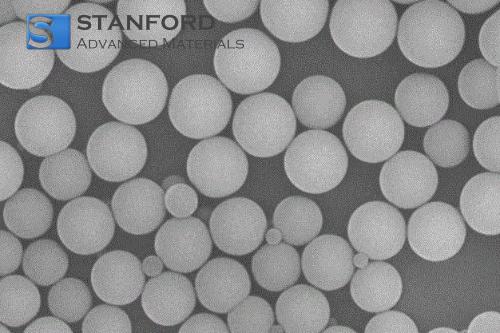

| Morphology | Spherical |

| Particle Size | 50nm, 100nm, 1-45um, etc. |

| Purity | >99.9% |

| MSDS/SDS |

Spherical Tantalum Powder (Ta) features high purity, uniform particle size, complete surface structure, easy dispersion, large specific surface area and high surface activity. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Spherical Tantalum Powder (Ta).

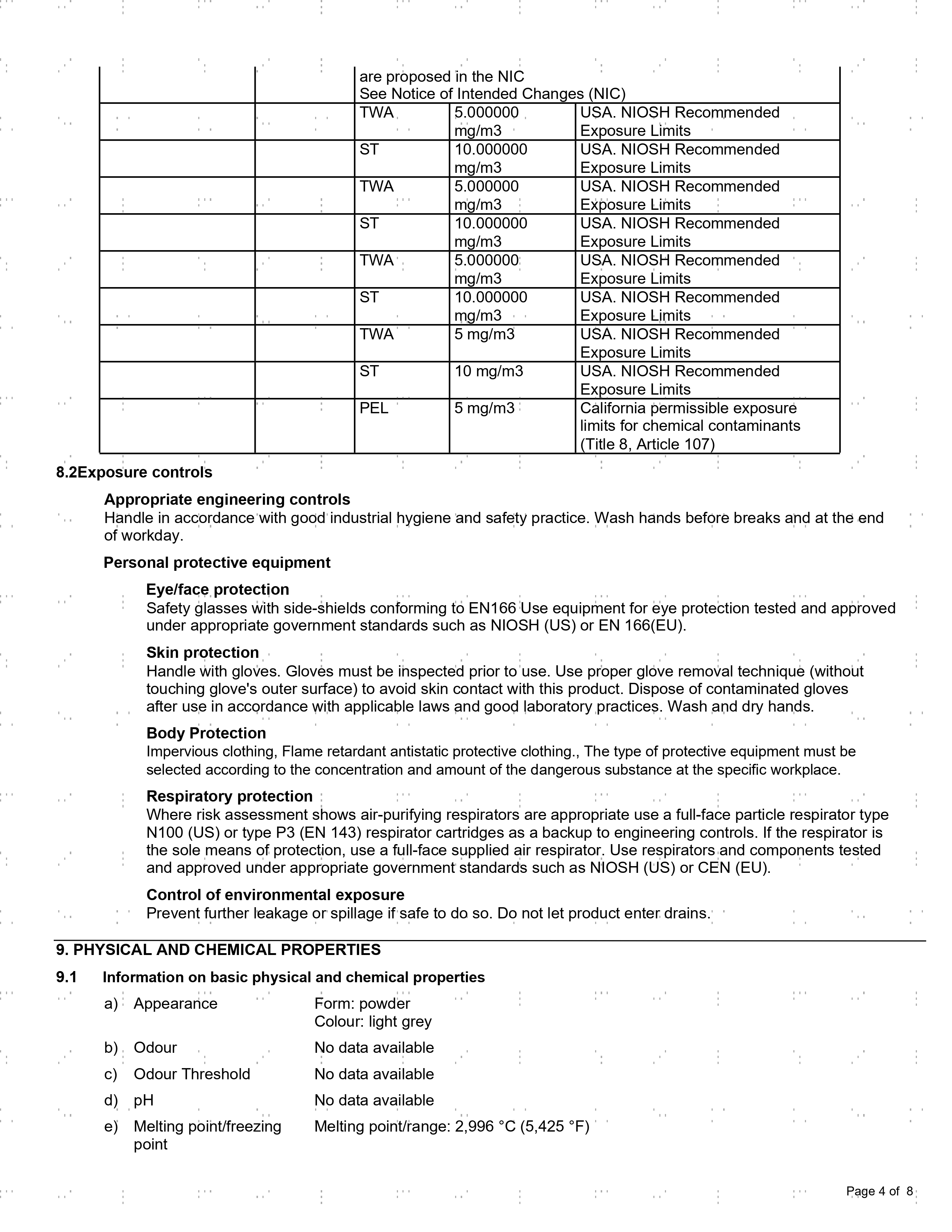

Related products: Nano Tantalum Powder, Micro Tantalum Powder, Capacitor Grade Tantalum Powder (4V-40V)

Spherical Tantalum Powder (Ta) Description

Spherical Tantalum Powder (Ta) has diverse uses in traditional & high-tech industries like cold spraying, plasma spraying raw materials, high-purity target alloy additives, SLM manufactures surgical metal implants, orthopedic prostheses, and additive manufacturing of acid-resistant and corrosion-resistant complex shielding parts. It features high purity, uniform particle size, complete surface structure, easy dispersion, large specific surface area and high surface activity. Tantalum capacitors are the most widely used capacitor products in the field of military electronics. The size of electronic products is becoming smaller and smaller, and tantalum capacitors are required to develop in the direction of miniaturization and high capacity.

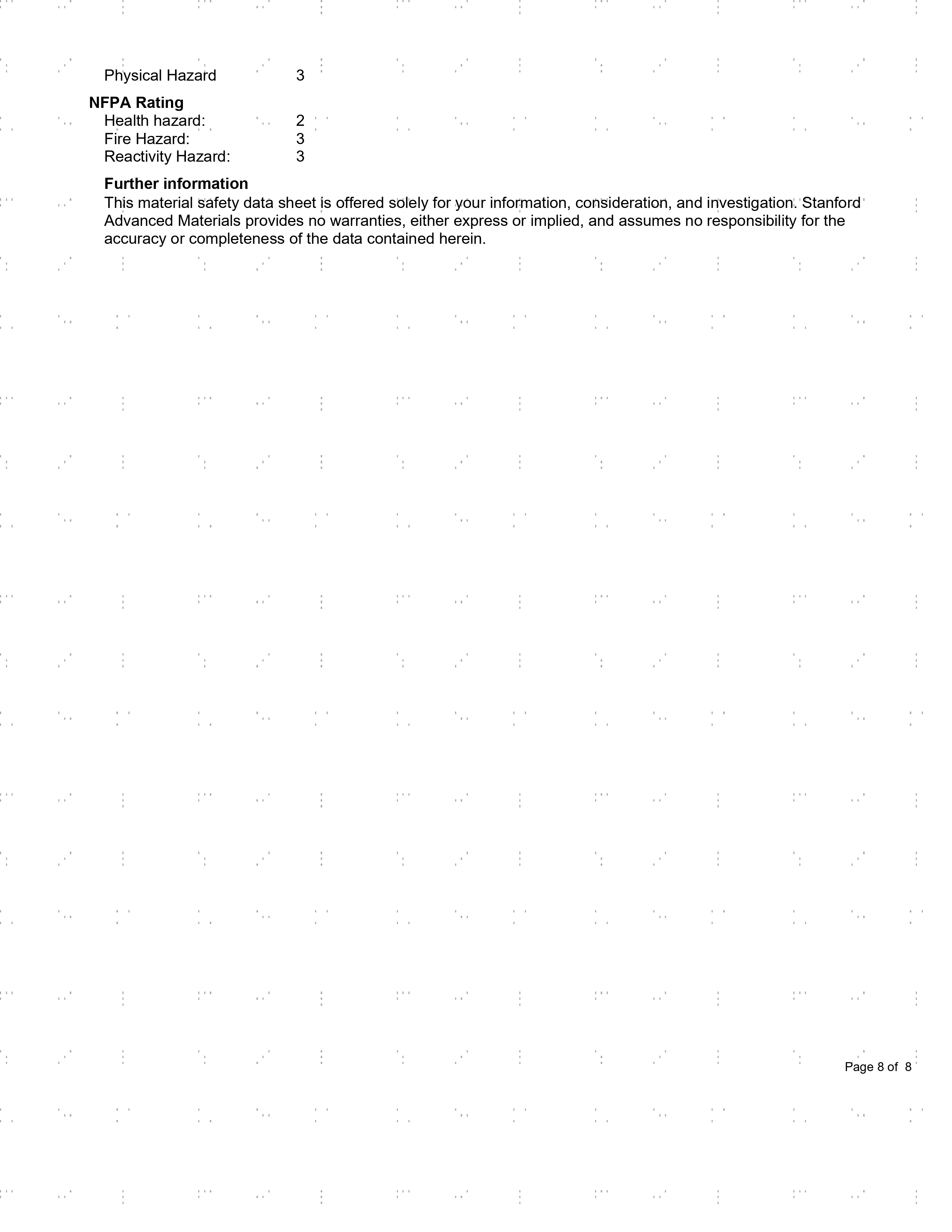

Spherical Tantalum Powder (Ta) Specifications

- Ta (50nm)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.8 |

|

Powder Morphology |

Particle Size Distribution (nm) |

Specific Surface Area (m2/g) |

||||

|

D10 |

D50 |

D90 |

||||

|

Spherical |

0-30 |

50-60 |

<300 |

≥10.0 |

||

- Ta (100nm)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.5 |

|

Powder Morphology |

Particle Size Distribution (nm) |

Specific Surface Area (m2/g) |

||||

|

D10 |

D50 |

D90 |

||||

|

Spherical |

30-60 |

80-100 |

<1000 |

≥8.0 |

||

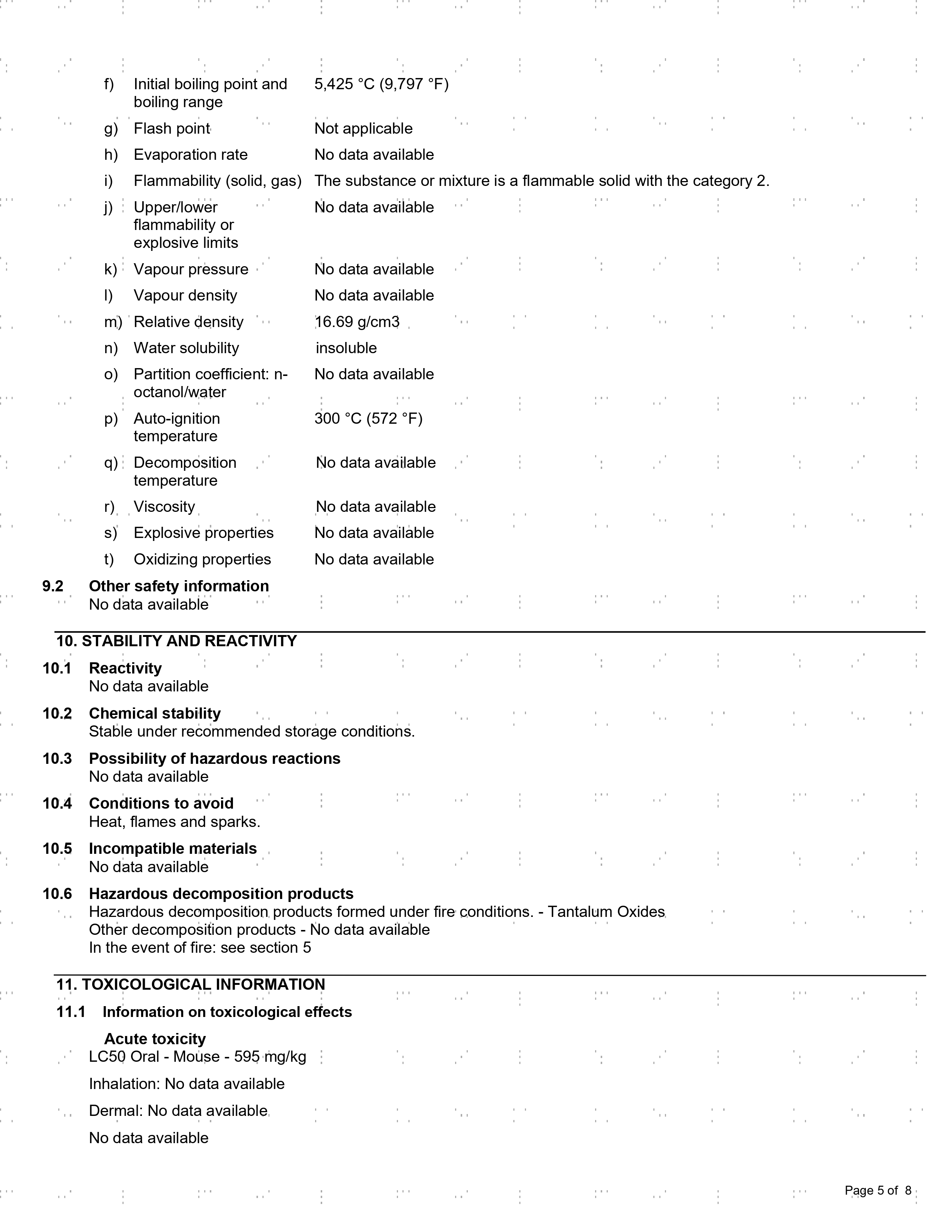

- Ta (1-10um)

|

Ta (%) |

Ti(%) |

W(%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.08 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Tap Density (g/cm3) |

||||

|

D10 |

D50 |

D90 |

||||

|

>94 |

>1 |

5±2 |

<10 |

≥10.5 |

||

- Ta (5-25um)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

<0.02 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Bulk Density (g/cm3) |

Tap Density (g/cm3) |

Fluidity (s/50g) |

||

|

D10 |

D50 |

D90 |

||||

|

>94 |

≥5 |

15±3 |

≤25 |

≥10.0 |

≥10.5 |

≤8.0 |

- Ta (15-45um)

|

Ta (%) |

Ti (%) |

W (%) |

Mo (%) |

Cr (%) |

Fe (%) |

O (%) |

|

>99.9 |

<0.001 |

<0.001 |

<0.001 |

<0.0001 |

<0.01 |

≤0.01 |

|

Sphericity (%) |

Particle Size Distribution (um) |

Bulk Density (g/cm3) |

Tap Density (g/cm3) |

Fluidity (s/50g) |

||

|

D10 |

D50 |

D90 |

||||

|

>94 |

>15 |

30±3 |

<45 |

≥9.5 |

≥10.0 |

≤6.0 |

*The company can customize Tantalum Metal Spherical Powder in any particle size range from 1 to 150μm according to customer requirements. The above product information is theoretical data; please contact us for more detailed information.

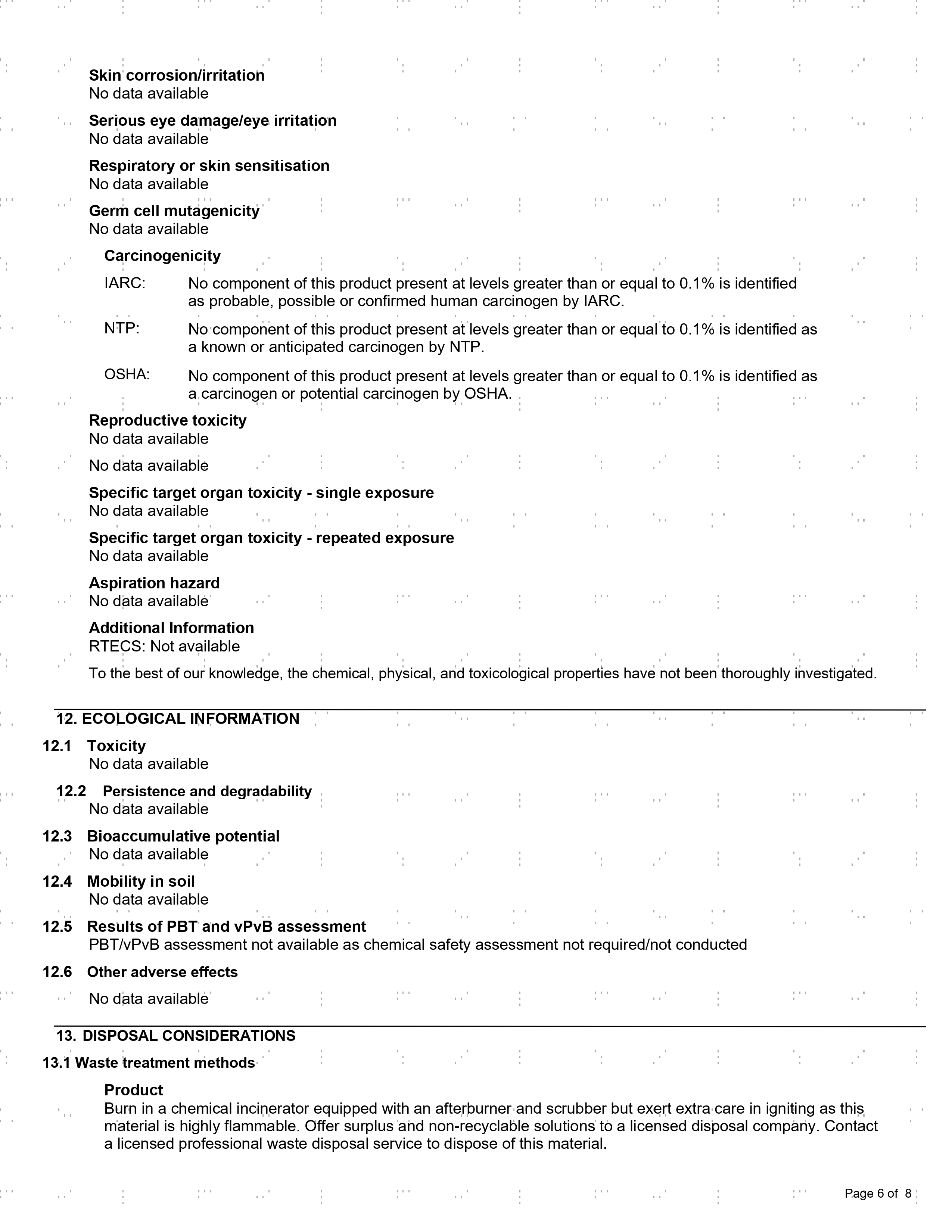

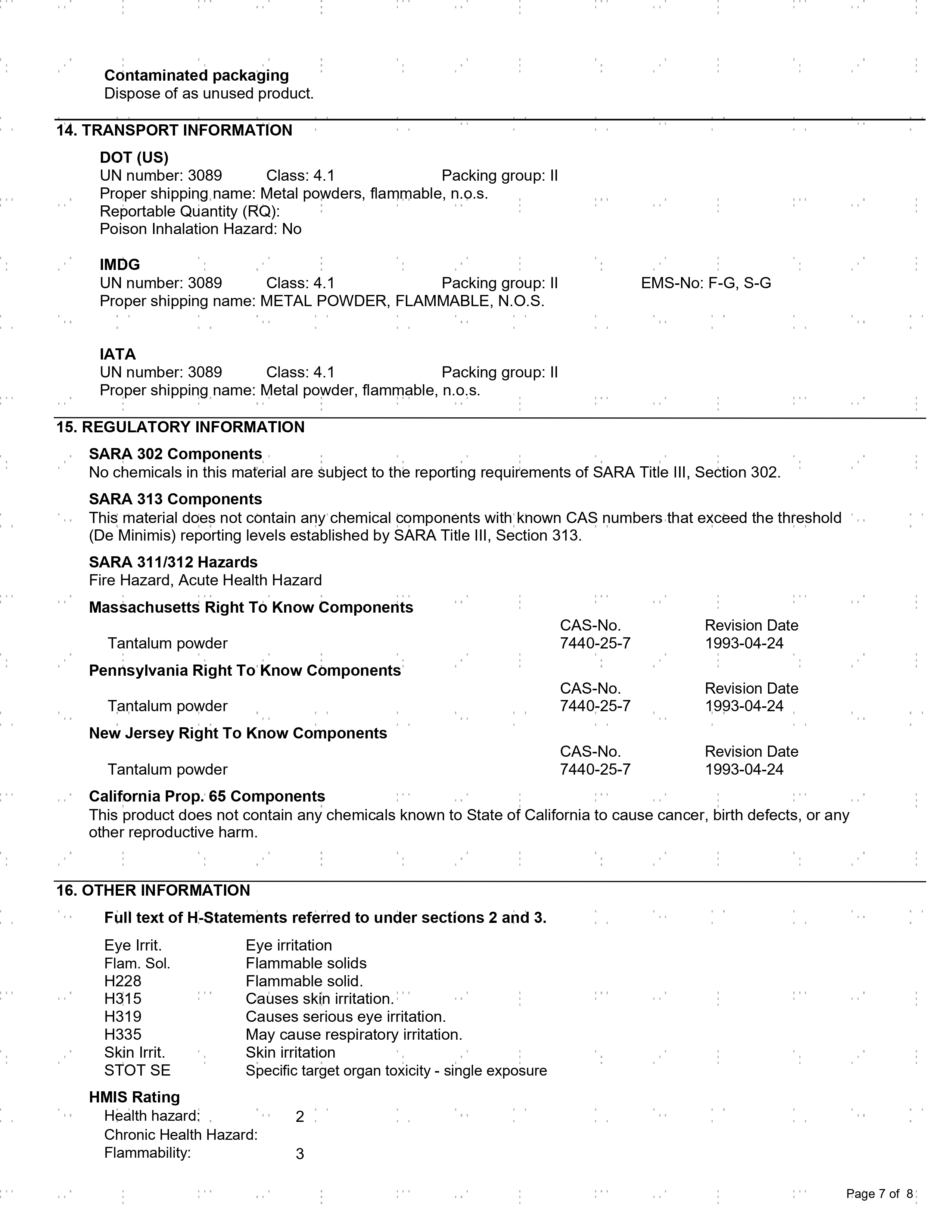

Spherical Tantalum Powder (Ta) Applications

Spherical Tantalum Powder (Ta) boasts diverse applications across traditional and high-tech industries. It serves as a key ingredient in advanced manufacturing techniques like cold spraying and plasma spraying, providing raw materials for these processes. Additionally, it plays a vital role as a high-purity target alloy additive, enhancing alloy properties for various applications.

In the realm of advanced manufacturing, this powder is crucial for Selective Laser Melting (SLM), facilitating the production of intricate surgical metal implants, including orthopaedic prostheses. Furthermore, it finds utility in additive manufacturing for crafting acid-resistant and corrosion-resistant complex shielding parts. In summary, Spherical Tantalum Powder is a versatile material with essential roles in advancing industries such as healthcare and materials engineering.

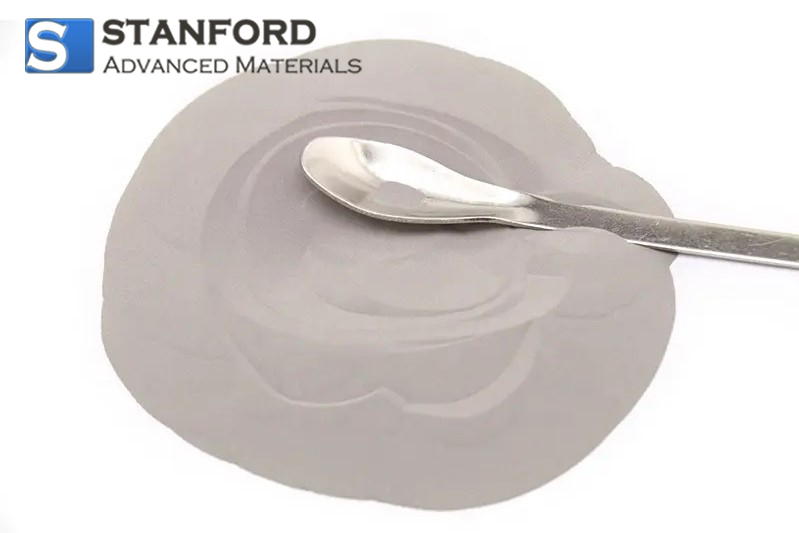

Spherical Tantalum Powder (Ta) Packaging

Our Spherical Tantalum Powder (Ta) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

FAQs

Q1. What is Spherical Tantalum Powder?

Spherical Tantalum Powder is a high-purity, spherical form of tantalum metal, widely used in various industrial applications that require superior performance in high-temperature, corrosion-resistant, and electronic environments. The spherical shape of the powder enhances its flowability and suitability for additive manufacturing processes like 3D printing and other powder metallurgy techniques.

Q2. What are the applications of Spherical Tantalum Powder?

Spherical Tantalum Powder is used in industries that demand high corrosion resistance, heat tolerance, and excellent electrical conductivity, including:

- Aerospace: For manufacturing turbine blades, rocket nozzles, and other components exposed to extreme temperatures.

- Electronics: In the production of capacitors, resistors, and other electronic components.

- Medical: For implants and surgical tools due to tantalum’s biocompatibility.

Q3. What are the main uses of Spherical Tantalum Powder in 3D printing?

Spherical Tantalum Powder is commonly used in metal 3D printing (specifically Selective Laser Melting (SLM) and Electron Beam Melting (EBM)) to produce high-performance parts for industries like aerospace, medical, and automotive. Its spherical shape allows for smooth, consistent powder bed layers, making it ideal for high-precision printing processes.

Related articles:

LATEST RECOMMENDED

Powder.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!