Machining Speeds and Feeds in CNC Machining

Introduction

Machining speeds and feeds play a critical role in CNC machining, affecting tool life, surface finish, and overall efficiency. Proper calculation of these parameters ensures optimal performance and minimizes wear and tear on equipment.

Importance of Speeds and Feeds

Selecting the appropriate speeds and feeds is vital for:

- Tool Longevity: Preventing excessive wear and extending tool life.

- Surface Quality: Achieving desired surface finishes.

- Production Efficiency: Balancing machining time with performance.

Calculating Machining Speeds and Feeds

The calculation of speeds and feeds involves several factors:

Cutting Speed (Vc)

Cutting speed refers to the speed at which the cutting tool engages the material. It is usually measured in meters per minute (m/min).

Feed Rate (F)

Feed rate is the distance the tool advances for each revolution of the workpiece, typically measured in millimeters per minute (mm/min).

Recommended Speeds and Feeds for Common Materials

|

Material |

Cutting Speed (m/min) |

Feed Rate (mm/min) |

|

200 |

0.2 |

|

|

Stainless Steel |

100 |

0.15 |

|

80 |

0.1 |

|

|

Cast Iron |

120 |

0.18 |

For more information, please check Stanford Advanced Materials (SAM).

Factors Influencing Speeds and Feeds

Several factors affect the optimal speeds and feeds:

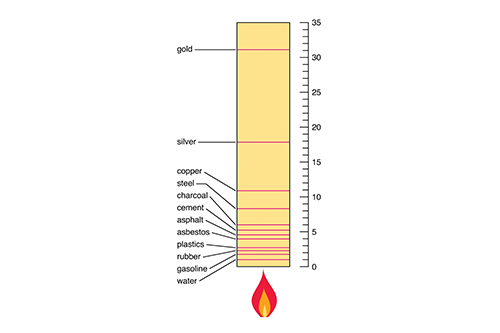

- Material Hardness: Harder materials require slower speeds.

- Tool Material: Carbide tools can handle higher speeds than high-speed steel.

- Machine Capabilities: The power and rigidity of the CNC machine determine feasible parameters.

Frequently Asked Questions

What is the difference between speed and feed in CNC machining?

Speed refers to how fast the cutting tool moves relative to the workpiece, while feed is the rate at which the tool advances into the material.

How do material properties affect speeds and feeds?

Harder materials typically require lower speeds and feeds to prevent tool wear and ensure quality machining.

Can incorrect speeds and feeds lead to tool damage?

Yes, using inappropriate speeds and feeds can cause excessive tool wear, breakage, or poor surface finish.

How does CNC technology aid in calculating speeds and feeds?

CNC machines use precise control systems that allow for accurate calculation and adjustment of speeds and feeds based on programmed parameters.

What tools are essential for calculating machining speeds and feeds?

Machining speed calculators, tool manufacturers' guidelines, and CNC machine software are essential for accurate calculations.