Creep in Metallurgy and Alloys

Understanding Creep

Creep is a critical phenomenon in the field of metallurgy, referring to the slow and progressive deformation of materials under constant stress over extended periods. This behavior becomes particularly significant at high temperatures, where materials like metals and alloys can undergo noticeable changes in shape and size. Understanding creep is essential for designing components that can withstand long-term operational stresses without failure.

Factors Affecting Creep in Alloys

Several factors influence the creep behavior of alloys, including:

Temperature

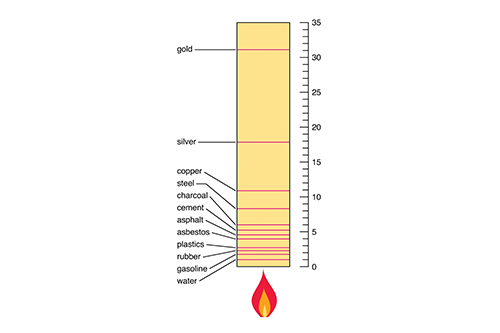

Higher temperatures generally accelerate creep, as increased thermal energy allows atoms within the alloy to move more freely, facilitating deformation.

Stress

The level of applied stress directly impacts the rate of creep. Higher stresses can lead to faster deformation rates.

Material Composition

The specific composition of an alloy, including the types and concentrations of its constituent elements, plays a crucial role in determining its creep resistance.

Microstructure

The internal structure of an alloy, such as grain size and phase distribution, affects how easily dislocations can move, influencing creep behavior.

Applications and Implications of Creep Resistance

Creep resistance is vital in industries where materials are subjected to high temperatures and stresses for prolonged periods. Key applications include:

- Aerospace Engineering: Components like turbine blades in jet engines must resist creep to maintain structural integrity under extreme conditions.

- Power Generation: Boiler tubes and other components in power plants operate at high temperatures, requiring materials with excellent creep resistance.

- Automotive Industry: Engine parts exposed to high temperatures and stresses benefit from alloys designed to minimize creep.

Understanding and mitigating creep can lead to longer-lasting components, improved safety, and enhanced performance across these industries.

Methods to Improve Creep Resistance

Enhancing the creep resistance of alloys involves several strategies:

Alloying

Adding specific elements such as chromium, nickel, or molybdenum can strengthen the alloy and improve its ability to resist creep.

Heat Treatment

Processes like annealing and quenching can refine the microstructure of an alloy, reducing grain size and enhancing creep resistance.

Grain Boundary Engineering

Optimizing grain boundaries to hinder dislocation movement can significantly improve an alloy's resistance to creep.

Surface Treatments

Coatings and surface modifications can protect alloys from oxidation and other high-temperature degradation processes that contribute to creep.

Creep Behavior of Common Alloys

|

Alloy Type |

Common Applications |

Creep Resistance Characteristics |

|

Jet engine components, power plant turbines |

High creep resistance at elevated temperatures due to solid solution strengthening and precipitation hardening |

|

|

Stainless Steels |

Automotive exhaust systems, industrial machinery |

Moderate creep resistance enhanced by alloying elements like chromium and molybdenum |

|

Titanium Alloys |

Aerospace structures, high-performance engines |

Good creep resistance with low density, suitable for high-stress environments |

|

Gas turbines, aerospace engines |

Exceptional creep resistance through complex microstructures and stable phase formations |

Frequently Asked Questions

What is creep in metallurgy?

Creep is the gradual and permanent deformation of a material under constant stress, especially at high temperatures over long periods.

Why is creep resistance important in alloys?

Creep resistance ensures that components maintain their structural integrity and functionality under sustained high-stress and high-temperature conditions.

Which industries are most affected by creep?

Industries such as aerospace, power generation, and automotive heavily rely on materials with high creep resistance to ensure the longevity and safety of their components.

How can the creep resistance of an alloy be improved?

Creep resistance can be enhanced by alloying with specific elements, optimizing heat treatment processes, engineering grain boundaries, and applying surface treatments.

Are there specific alloys designed for high creep resistance?

Yes, nickel-based superalloys and certain titanium alloys are specifically engineered to exhibit excellent creep resistance for demanding applications.