Compressive Strength: Basics and Examples

What Is Compressive Strength?

Compressive strength is a fundamental property of materials, indicating their ability to withstand loads that reduce their size. It is a critical factor in the design and analysis of structures, ensuring that buildings, bridges, and other constructions can support the expected loads without failure. Understanding compressive strength helps engineers select appropriate materials and design safe, reliable structures.

Several factors influence the compressive strength of a material:

- Material Composition: The type and quality of materials used significantly impact compressive strength.

- Curing Conditions: Proper curing enhances the material's ability to resist compressive forces.

- Age of the Material: Over time, materials like concrete can gain strength, improving their compressive capacity.

- Environmental Conditions: Exposure to elements such as moisture and temperature can affect compressive strength.

Compressive vs. Tensile Strength

While compressive strength measures a material's ability to withstand pushing forces, tensile strength assesses its ability to resist pulling forces. Both properties are essential in engineering, as structures often experience a combination of compressive and tensile stresses.

Compressive Strength and Tensile Strength in Construction

Balancing Both Strengths

In construction, it's crucial to balance compressive and tensile strengths to create structures that can handle various stressors. For instance, combining materials with high compressive strength (like concrete) with those that have high tensile strength (like steel) results in robust and resilient structures.

Practical Examples

- Reinforced Concrete: Combines concrete's high compressive strength with steel's tensile strength, providing a balanced and durable construction material.

- Composite Materials: Utilize the strengths of different materials to achieve desired properties for specific applications.

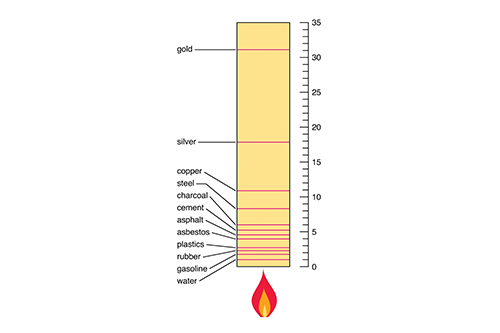

Compressive Strength of Common Materials

|

Material |

Compressive Strength (MPa) |

Tensile Strength (MPa) |

|

Concrete |

20-40 |

2-5 |

|

250-550 |

400-700 |

|

|

Wood (Oak) |

40-50 |

90-100 |

|

Brick |

5-25 |

2-7 |

|

200-400 |

150-300 |

Measuring Compressive Strength

Standard Testing Methods

Compressive strength is typically measured using standardized tests that apply gradually increasing loads to a specimen until failure occurs. The maximum load sustained by the material before failure is recorded and used to calculate its compressive strength.

Importance of Accurate Measurement

Accurate measurement of compressive strength ensures that materials meet the required specifications for safety and performance in their intended applications.

Frequently Asked Questions

What is the difference between compressive and tensile strength?

Compressive strength measures a material's ability to withstand pushing or

squeezing forces, while tensile strength measures its ability to resist pulling

or stretching forces.

Why is compressive strength important in construction?

Compressive strength is crucial in construction to ensure that materials can

support the loads and stresses they will encounter, maintaining the structural

integrity and safety of buildings and infrastructure.

How is compressive strength tested?

Compressive strength is tested by applying gradually increasing loads to a

material specimen until it fails, with the maximum load sustained being

recorded to calculate its compressive strength.

Can compressive strength and tensile strength be improved

simultaneously?

Yes, through material selection, treatment processes, and design techniques,

both compressive and tensile strengths can be enhanced to achieve desired

performance characteristics.

What materials typically have high compressive strength?

Materials like concrete, steel, and certain composites are known for their high

compressive strength, making them suitable for various structural applications.