Castability of Metals

Introduction to Castability

Castability refers to the ease with which a material can be shaped into a desired form through the casting process while maintaining high quality. It is a critical factor in manufacturing, influencing both the efficiency and the cost-effectiveness of production. Understanding the castability of metals helps manufacturers select appropriate materials and optimize casting parameters to achieve superior results.

Castability of Metals

Castability of metals pertains to a metal's ability to flow into a mold and fill it completely without defects. High castability ensures that the final product has the desired shape, minimal porosity, and uniform mechanical properties. This characteristic is essential for producing complex geometries and intricate designs that are often required in industries such as automotive, aerospace, and consumer electronics.

Factors Affecting Castability

Several factors influence the castability of metals, each playing a significant role in the quality and feasibility of the casting process. Key factors include:

Chemical Composition

The alloying elements present in a metal can significantly affect its fluidity, solidification behavior, and susceptibility to defects. For instance, elements like silicon and manganese can enhance fluidity, while excessive sulfur can lead to hot tearing.

Temperature Control

Proper temperature management during melting and pouring is crucial. If the metal is too viscous, it may not flow adequately into the mold, leading to incomplete fill or defects such as cold shuts. Conversely, excessively high temperatures can cause excessive oxidation and gas porosity.

Mold Design and Material

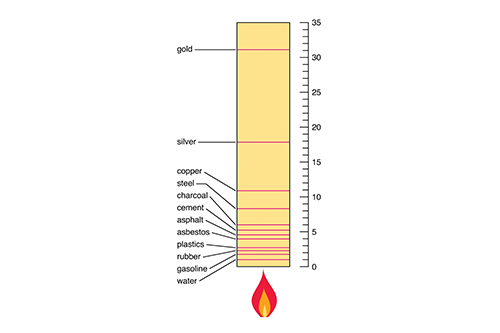

The design of the mold, including its shape, size, and the material used, impacts the flow of metal. A well-designed mold facilitates uniform filling and cooling, reducing the likelihood of defects. Materials with high thermal conductivity can help in achieving consistent cooling rates.

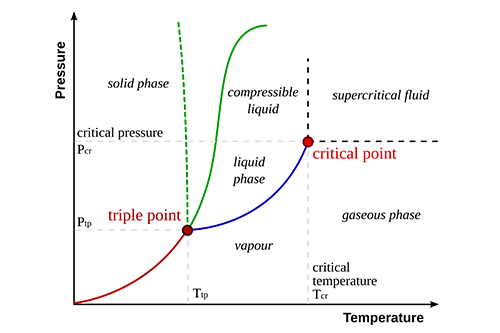

Solidification Rate

The rate at which the metal solidifies affects the grain structure and mechanical properties of the casting. Rapid cooling can lead to fine grain structures, enhancing strength and toughness, while slow cooling may result in coarse grains and reduced mechanical performance.

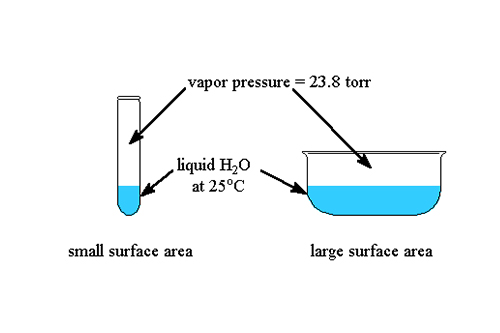

Surface Tension and Viscosity

Low surface tension and appropriate viscosity are desirable for metals with high castability. These properties allow the metal to flow smoothly into the mold, filling intricate details without trapping air or forming defects.

|

Factor |

Impact on Castability |

|

Chemical Composition |

Influences fluidity, solidification, and defect formation |

|

Temperature Control |

Affects metal flow, oxidation, and porosity |

|

Mold Design |

Determines metal flow patterns and cooling rates |

|

Solidification Rate |

Impacts grain structure and mechanical properties |

|

Surface Tension |

Affects the metal's ability to flow and fill the mold |

|

Viscosity |

Determines ease of metal flow and ability to capture details |

Frequently Asked Questions

What is castability in metal casting?

Castability refers to how easily a metal can be poured into a mold and take the

desired shape without defects, ensuring high-quality cast products.

Which metals generally have high castability?

Metals like aluminum, zinc, and certain steel alloys typically exhibit high

castability due to their favorable fluidity and solidification characteristics.

How does mold material affect castability?

Mold materials with high thermal conductivity can promote uniform cooling,

reducing defects and improving the flow of metal, thereby enhancing

castability.

Can alloy composition be adjusted to improve castability?

Yes, adding or adjusting alloying elements can modify the metal’s fluidity,

solidification behavior, and overall castability to meet specific requirements.

What role does temperature play in the casting process?

Maintaining the optimal temperature ensures that the metal flows smoothly into

the mold and solidifies properly, minimizing defects and ensuring high-quality

castings.