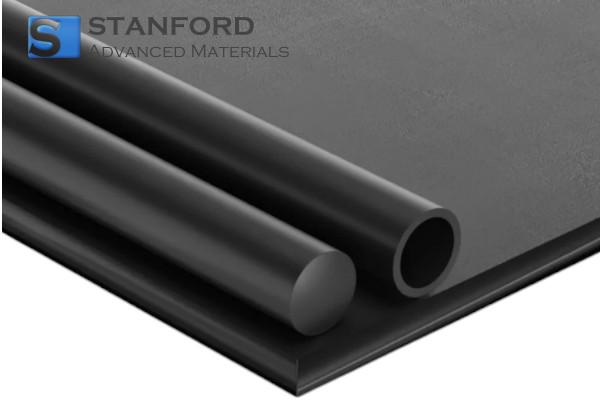

Carbon Fiber Reinforced Polyimide Description

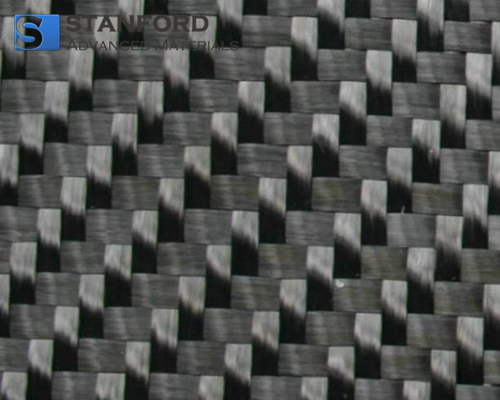

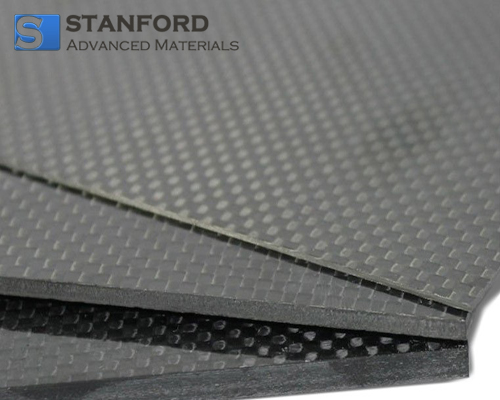

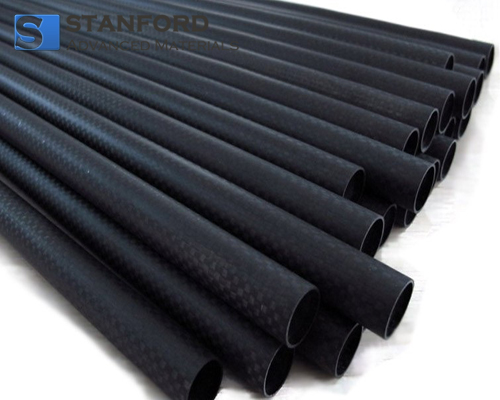

Carbon Fiber Reinforced Polyimide (CFRP) is a cutting-edge composite material renowned for its exceptional thermal stability, mechanical strength, and chemical resistance. The polyimide matrix provides superior heat resistance, maintaining structural integrity and performance at temperatures exceeding 250°C, making it suitable for high-temperature applications. Combined with carbon fibers, CFRP offers a high strength-to-weight ratio, excellent tensile and flexural strength, and rigidity. The material also boasts minimal moisture absorption and outstanding resistance to harsh chemicals, ensuring durability in extreme environments. These properties make CFRP highly suitable for aerospace components, advanced electronics, and high-performance engineering applications where reliability under challenging conditions is essential.

Carbon Fiber Reinforced Polyimide Specifications

|

Formula

|

Carbon Fiber - Polyimide

|

|

Dimensions

|

Customized

|

|

Density

|

1.6 - 1.9 g/cm3

|

|

Tensile Strength

|

1,800 – 4,500 MPa

|

|

Thermal Conductivity

|

0.3 – 1.0 W/m·K

|

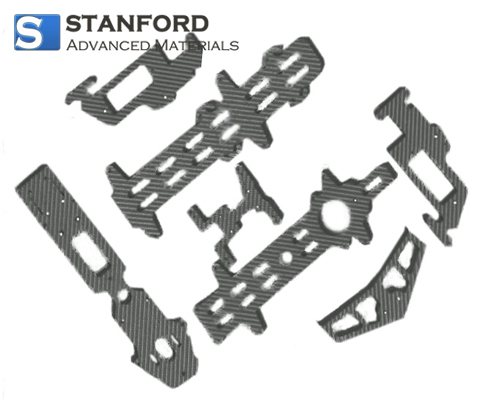

Carbon Fiber Reinforced Polyimide Applications

Carbon Fiber Reinforced Polyimide (CFRP) is utilized in a range of advanced applications due to its remarkable thermal stability, mechanical strength, and chemical resistance. In the aerospace industry, CFRP is used for aircraft components, satellite structures, and other space equipment, where its high strength, low weight, and ability to withstand extreme temperatures are crucial. It is also applied in electronics and electrical engineering for high-frequency circuits and electrical insulators, benefiting from its low dielectric constant and excellent electrical insulation properties. Additionally, CFRP is employed in high-temperature applications such as engine components and aerospace propulsion systems, where it endures extreme conditions. The material is also used in advanced manufacturing for high-performance structural components and specialty coatings, as well as in medical devices for prosthetics and implants, providing durable and lightweight solutions. These diverse applications highlight CFRP's versatility and capability to perform reliably in demanding environments.

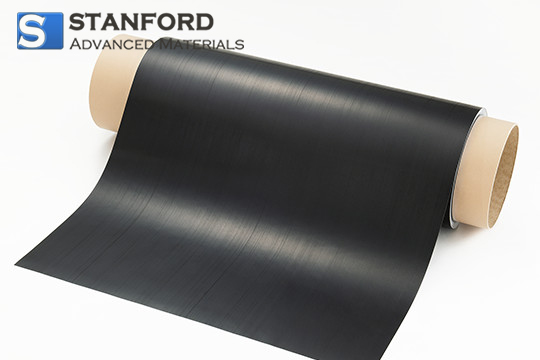

Carbon Fiber Reinforced Polyimide Packing

Our Carbon Fiber Reinforced Polyimide is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Carbon Fiber Reinforced Polyimide FAQ

Q1: What are the main advantages of Carbon Fiber Reinforced Polyimide compared to other composites?

A1: CFRP offers exceptional thermal stability, maintaining its mechanical properties at temperatures up to 300°C, which is superior to many other composites. It also provides a high strength-to-weight ratio, excellent chemical resistance, and low moisture absorption, making it ideal for high-temperature and demanding applications.

Q2: How does Carbon Fiber Reinforced Polyimide perform in high-temperature environments?

A2: CFRP performs exceptionally well in high-temperature environments, with thermal stability up to around 300°C. This makes it suitable for applications in aerospace and automotive industries where components are exposed to extreme heat.

Q3: Can Carbon Fiber Reinforced Polyimide be used in electronic applications?

A3: Yes, CFRP is suitable for high-frequency electronic applications due to its low dielectric constant and excellent electrical insulation properties. It is used in substrates and components where reliable performance in electronic circuits is required.