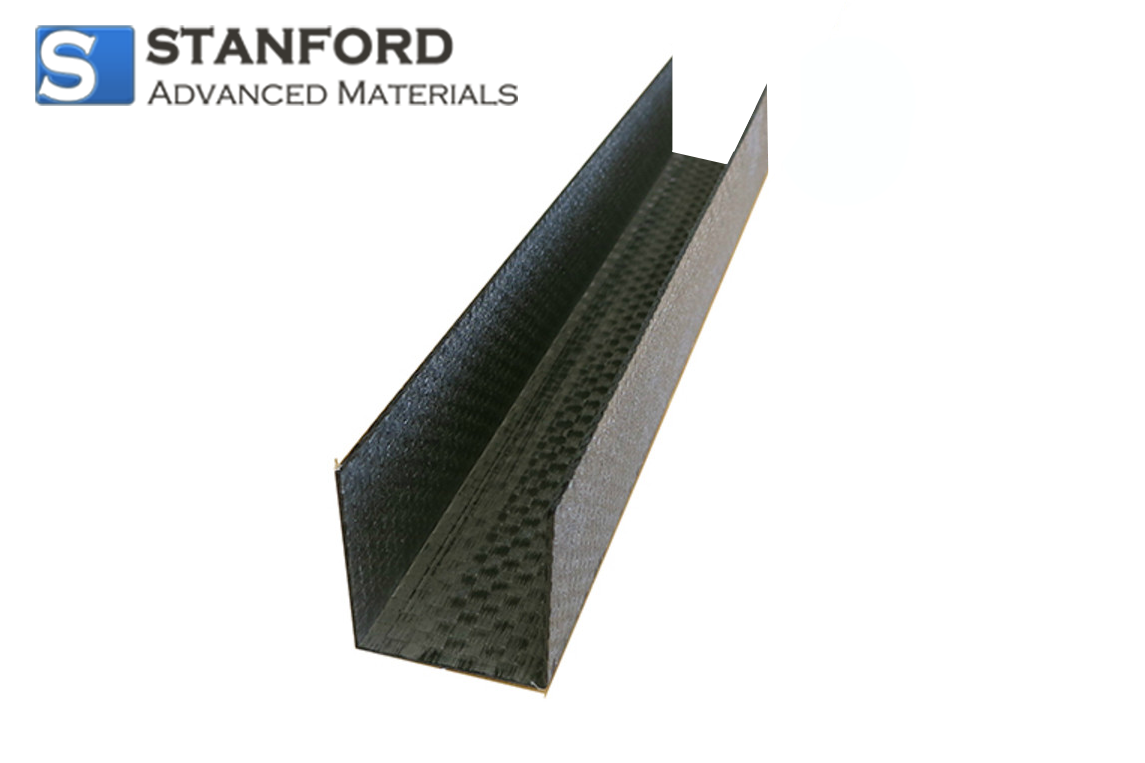

Carbon Composite (CFC) U-Channel Description

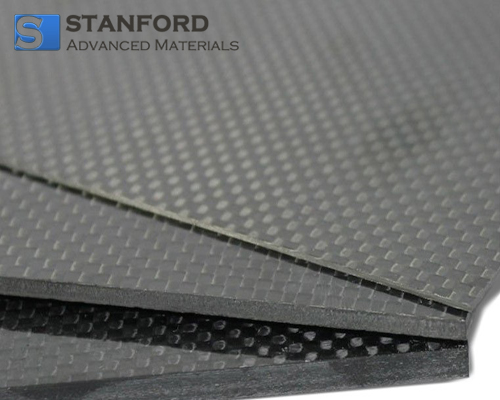

Carbon Composite (CFC) U-Channel is a lightweight, carbon fiber reinforced, high-temperature treated composite material. It offers superior strength and fracture resistance compared with graphite. It features excellent resistance to heat, oxidation, thermal shock, and chemical corrosion. The product has high interlaminar shear strength, exhibits in-plane isotropy, and is stable to 3600F (2000C).

Carbon Composite (CFC) U-Channel Specifications

|

Size

|

Customized

|

|

Grade

|

GS-CFC200

|

|

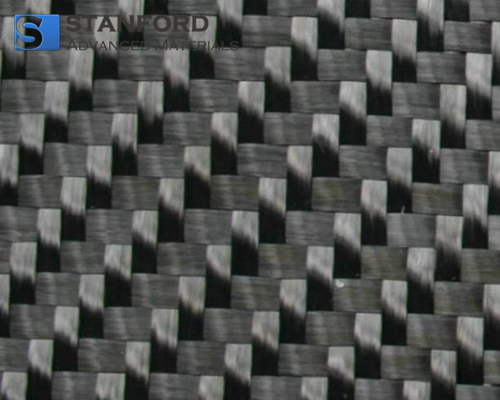

Fiber Alignment

|

0°/90°

|

|

Density (g/cm3)

|

1.6

|

|

Flexural Strength (MPa)

|

160

|

|

Tensile Strength (MPa)

|

260

|

|

Compressive Strength (MPa)

|

90

|

|

Shore Hardness

|

80

|

|

Thermal Conductivity (W/m·K)

|

27

|

Carbon Composite (CFC) U-Channel Applications

1. Ultra-High Temperature Vacuum Furnaces: CFC U-Channels are used as structural components in vacuum furnaces that operate at extremely high temperatures (above 2000°C). Their stability under such conditions makes them suitable for supporting insulation materials, heating elements, and other internal components.

2. Atmosphere Furnaces: In atmosphere-controlled furnaces, CFC U-Channels serve as supports and structural parts that can withstand a variety of environments, including inert, reducing, or slightly oxidizing atmospheres. They maintain their mechanical integrity and thermal stability under different atmospheric conditions.

3. Heating Elements: The U-shaped design of CFC U-Channels makes them ideal for use in heating elements for ultra-high temperature applications. Their excellent thermal conductivity and low thermal expansion help ensure even heat distribution and reduce thermal stresses.

4. Hearth Rails: CFC U-Channels are commonly used as hearth rails in furnaces to support workpieces, trays, or materials undergoing heat treatment. Their ability to withstand thermal cycling and maintain structural integrity at high temperatures makes them well-suited for processes such as sintering, annealing, and carburizing.

5. Automotive Parts: In high-performance automotive manufacturing, CFC U-Channels are used in components exposed to high temperatures, such as brake systems, engine parts, and exhaust components. Their lightweight nature and high heat resistance help enhance the performance and longevity of these parts.

6. Support Structures in Furnaces: As support structures within furnaces, CFC U-Channels provide mechanical stability for insulation, heating elements, and other furnace components. Their high strength-to-weight ratio ensures reliable support without adding excessive weight to the furnace system.

7. Fixtures and Racks for Heat Treatment: In heat treatment applications, CFC U-Channels are used to fabricate fixtures and racks that hold parts during processes like hardening, tempering, or stress-relieving. Their resistance to high temperatures and thermal shock is crucial for maintaining part alignment and preventing distortion.

8. Semiconductor Manufacturing: In semiconductor fabrication, CFC U-Channels are used in high-temperature processing equipment, such as chemical vapor deposition (CVD) systems. Their thermal stability, low outgassing, and chemical inertness help maintain a clean processing environment and support critical components.

9. Laboratory and Research Equipment: For high-temperature laboratory experiments, CFC U-Channels can be used in experimental setups, heating apparatus, or structural components. Their ability to resist extreme temperatures while maintaining mechanical integrity makes them ideal for research involving thermal processing.

10. Aerospace Thermal Protection: CFC U-Channels can be used in aerospace applications, such as thermal protection systems and heat shields. Their high-temperature performance and resistance to thermal cycling make them suitable for components exposed to intense heat, like re-entry vehicles or high-speed aircraft.

Carbon Composite (CFC) U-Channel Packaging

Our Carbon Composite (CFC) U-Channel is carefully handled during storage and transportation to preserve the quality of our product in its original condition.