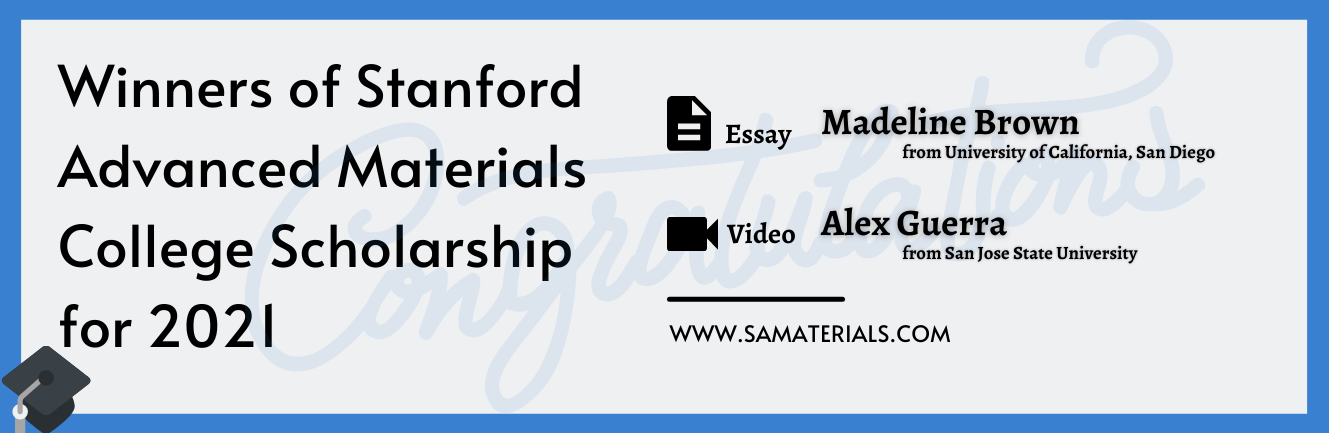

Winners of Stanford Advanced Materials College Scholarship for 2021

SAM's 2021 College Scholarship focuses on the impact of new technologies and new materials for our society. Advanced materials brought a bright future to us, but there are still various technology problems. Thus, SAM invited students to talk about what technological problem will pose the biggest challenge in the next decade. SAM also asked them to share previous projects that have solved a problem using advanced materials.

In the past few months, we have received around 150 essay submissions and 20 video submissions. All of these students have done a good job, and we hope that they all make great achievement in the future!

From these submissions, we finally selected two winners.

Madeline Brown

from University of California, San Diego

Thank you letter from Madeline Brown

Alex Guerra

from San Jose State University

Thank you letter from Alex Guerra

Here are their submissions.

Essay - Madeline Brown

The Scalpel’s Demise: A Look into the Future of Surgery

As the field of medicine has advanced, one practice is lodged in the archaic past. No matter the technological advancements of the field of surgery, the practice of actively opening the human body via incision calls to mind images of the barbaric practices of early medicine. Not only does it expose the body to disease via antibiotic-resistant microbes, but an incision of any kind will accrue scar tissue: an extremely painful post-surgical reminder for any patient. Addressing this problem will be no easy feat; however, utilizing advanced materials makes it a possibility.

My passion for improving surgical methods started close to home, with my mom. Midway through my freshman year of college, my mom found out she needed a heart valve replacement. The surgery was conducted using a minimally invasive procedure: an incision made in her right underarm traveling through an artery to the affected valve. After the surgery, my brother and I stayed with her in the recovery room; it was in this room I realized modern surgery was flawed. The entire time she was in pain, but it wasn’t her heart that hurt: it was the incision. As time progressed after the procedure, managing the complications associated with the incision became arduous. In an effort to prevent infection, daily cleanings and bandage replacements became the norm. Though post-surgical instructions were followed to a tee, my mother still suffered from pain in the area of the incision, likely due to scar tissue accumulation.To this day, she suffers from a constant reminder of her procedure, the unnecessary pain of her scar tissue. It was this notion, that this pain was unnecessary, that spurred me to create a method of surgery that could prevent scar tissue before it began: a surgical method without an incision.

The solution to advance surgery would be a strategic application of drug delivery devices. Namely, a combination of porous silicon particles and a polymer. The advantages of this hybrid system become apparent when analyzing its components. The silicon particles can be adjusted to hold specific drug payloads, while the polymer would be utilized to prevent the particles from migrating to unintended areas. The allure to using such a method lies in the notion that it can be tailored to a specific patient's needs as well as being near non-invasive. For example, a patient suffers an ischemic stroke, in order to diffuse the clot, silicon particles loaded with t-PA can be guided through the bloodstream to the locus of the clot and act to disperse it. This proves particularly advantageous as it directs the potentially toxic t-PA to an isolated point and has the ability to be maximally effective in clearing the clot.

Given adequate funding, I would begin testing the capabilities of a hybrid polymer-porous silicon hybrid drug delivery system. The scaffold for the drug-loaded particles would be polycaprolactone (PCL), as this FDA-approved polymer has been shown to effectively encapsulate silicon nanoparticles [1]. Second, porous silicon particles would be produced via electrochemical etching [2], these particles have the unique ability to be finely tuned to load various drugs. The “tuning” can be accomplished by altering the porosity and size of particles, optimizing both features to adequately accommodate a chosen payload. Depending on the intended function of the hybrid particle polymer delivery system, the drug-loaded would vary. For instance, if I were focused on revascularizing tissue, I would load various forms of VEGF (each shown to have a different impact in vascularization) into the silicon particles. Once the porous silicon particles are loaded with the desired drug they could be incorporated into the PCL via spray nebulization: combining the two solutions and spraying out of an airbrush. [3] When shot out of the airbrush, the PCL will form oriented fibers that, when focused, form a patch. Said patch can be cut for size and deployed into the body via a trocar; henceforth reducing the impact of an incision to the impact of a large vaccine.

In order to perform more complex procedures, a cadre of particle and polymer combinations must be used: particles to perform and close incisions, promote healing, etc. Each would demand its own separate research process, however, when brought together the system would revolutionize medicine. After all, a surgical system administered through an injection would yield a process not only less susceptible to antibiotic-resistant infections, but also less susceptible to the accumulation of painful scar tissue.

The evolution of medicine is dependent on recognizing its pitfalls, no matter how small they may be to an observer. In the case of modern surgery, we have fallen into the rhythm of causing harm to patients in order to heal their ailments. Although this seems like a noble trade off, we must not forget the oath all physicians are sworn to: “primum non nocere,”do no harm. Thus, in order to serve patients in the best capacity, we must find a way to abandon the scalpel in favor of nano and micro invasive techniques. By embracing these techniques, we can push the boundaries of medicine further to truly embrace the maxim of do no harm.

Citations

[1]Zuidema, J. M., Dumont, C. M., Wang, J., Batchelor, W. M., Lu, Y.-S., Kang, J., Bertucci, A., Ziebarth, N. M., Shea, L. D., Sailor, M. J., Porous Silicon Nanoparticles Embedded in Poly(lactic-co-glycolic acid) Nanofiber Scaffolds Deliver Neurotrophic Payloads to Enhance Neuronal Growth. Adv. Funct. Mater. 2020, 30, 2002560. https://doi.org/10.1002/adfm.202002560

[2]Qin, Z., Joo, J., Gu, L. and Sailor, M.J. (2014), Size Control of Porous Silicon Nanoparticles by Electrochemical Perforation Etching. Part. Part. Syst. Charact., 31: 252-256. https://doi.org/10.1002/ppsc.201300244

[3]Zuidema, J. M., Kumeria, T., Kim, D., Kang, J., Wang, J., Hollett, G., Zhang, X., Roberts, D. S., Chan, N., Dowling, C., Blanco-Suarez, E., Allen, N. J., Tuszynski, M. H., Sailor, M. J., Adv. Mater. 2018, 30, 1706785. https://doi.org/10.1002/adma.201706785

Video - Alex Guerra