Multi-Leaf Collimators: A Comprehensive Guide with Cases

What is a Multi-Leaf Collimator?

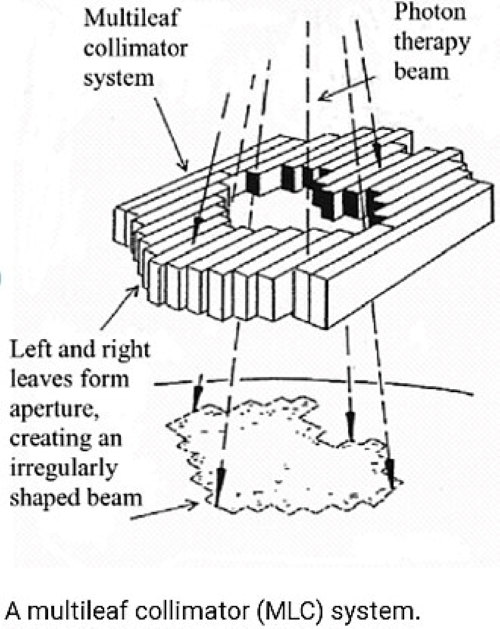

A Multi-Leaf Collimator (MLC) is an advanced device integrated into radiotherapy machines to shape and direct radiation beams with precision. Composed of numerous movable tungsten alloy leaves or shields, MLCs replace older methods, such as custom lead-based blocks, to achieve targeted radiation delivery.

The primary purpose of an MLC is to conform radiation beams to the shape of the tumor, minimizing exposure to surrounding healthy tissue. With its high-density construction and automated functionality, MLCs enable safer, more effective treatments.

How Multi-Leaf Collimators Work

[1]

[1]

An MLC consists of 20 to 80 tungsten alloy leaves, each independently movable and controlled by computer software. These leaves can slide in and out to shape the beam according to the tumor's geometry, creating a custom radiation field.

This automated process allows for:

- Dynamic shaping: Real-time adjustments during treatment.

- Intensity modulation: Varying radiation intensities across the field for more effective therapy.

- Healthy tissue protection: Shielding organs or tissues adjacent to the tumor.

Applications in Radiotherapy

MLCs are widely used in the treatment of cancers such as:

- Liver cancer: Protecting vital organs like the liver during therapy.

- Lung cancer: Shaping beams to bypass delicate tissues.

- Breast cancer: Shielding the heart and lungs from radiation exposure.

Their ability to create custom radiation fields makes them indispensable for advanced therapies like IMRT and Volumetric Modulated Arc Therapy (VMAT), where precision and control are paramount.

Transition from Cerrobend to Multi-Leaf Collimators

Traditionally, lead-based alloys like Cerrobend were used to create custom radiation blocks for beam shaping. These Cerrobend blocks were manually fabricated for each patient, requiring labor-intensive work and generating hazardous waste.

However, the transition to MLCs has largely eliminated the need for Cerrobend blocks, driven by:

- Advances in technology: MLCs provide dynamic beam shaping without manual intervention.

- Environmental concerns: Cerrobend production and disposal involve toxic materials.

- Operational efficiency: MLCs reduce preparation time, making treatment faster and more precise.

This shift represents a significant step forward for patient safety, environmental sustainability, and healthcare efficiency.

Case Study of Multi-Leaf Collimators (MLCs)

--Overview

Replacing Cerrobend blocks with tungsten alloy Multi-Leaf Collimators (MLCs) enhances radiation therapy precision while minimizing environmental and health impacts.

--Background

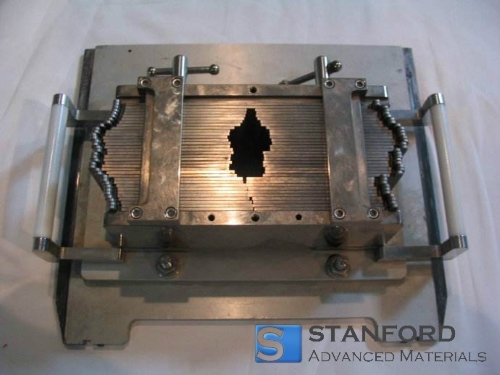

Historically, Cerrobend, a lead-based alloy, was widely used in radiation therapy for creating customized blocks to shape radiation beams. However, Cerrobend production generates hazardous waste and poses environmental challenges due to its toxicity. A healthcare professional approached Stanford Advanced Materials (SAM) for permission to use an image of Multi-Leaf Collimators (MLCs) to illustrate this transition in a presentation about waste management in hospitals. With advancements in technology, tungsten alloy MLCs have emerged as a safer and more sustainable alternative.

--Solution

SAM supported the educational initiative by providing the requested image and insights into tungsten alloy MLCs. Tungsten alloy, with a density between 17.0 g/cm³ and 18.6 g/cm³, offers superior radiation absorption, ensuring patient safety during treatment. Unlike Cerrobend, tungsten is non-toxic and non-polluting, making it an eco-friendly choice. Tungsten MLCs feature 20 to 80 computer-controlled, movable shields or leaves, allowing for the precise shaping of radiation fields. This capability reduces radiation exposure to healthy tissues and is particularly suited for treating liver, lung, and breast cancers.

--Result

The presentation effectively demonstrated the environmental and operational benefits of tungsten alloy MLCs over Cerrobend blocks. Healthcare professionals gained valuable insights into the advantages of MLCs, including:

- Enhanced safety: Shielding patients from unnecessary radiation exposure.

- Eco-friendliness: Eliminating hazardous waste associated with Cerrobend.

- Precision treatment: Generating arbitrarily shaped radiation fields with computer-controlled shields.

This initiative encouraged hospitals to transition to tungsten alloy MLCs, fostering safer and more sustainable cancer treatment practices while highlighting SAM’s role in promoting innovative, patient-centered technologies.

Materials for Multi-Leaf Collimators

The choice of materials is critical to the performance and safety of MLCs. Tungsten alloys are the gold standard due to their unique properties:

- High density: With a density between 17.0 g/cm³ and 18.6 g/cm³, tungsten alloy effectively absorbs radiation, minimizing leakage and ensuring patient safety.

- Non-toxicity: Unlike lead-based materials like Cerrobend, tungsten is non-toxic and eco-friendly, making it safer for both patients and medical staff.

- Durability: Tungsten alloys resist wear and corrosion, ensuring longevity and consistent performance in radiotherapy equipment.

Although other materials like depleted uranium and tantalum have been explored, tungsten alloys remain the preferred choice due to their balance of performance, safety, and sustainability.

Conclusion

Multi-Leaf Collimators are transforming cancer treatment by enabling precise, efficient, and environmentally sustainable radiation therapy. The transition from traditional Cerrobend blocks to tungsten alloy MLCs represents a significant leap forward in medical technology, improving patient outcomes and reducing environmental impact. For more advanced materials and related cases, please check Stanford Advanced Materials (SAM).

Reference:

[1] Multileaf collimator. (2024, May 16). In Wikipedia. https://en.wikipedia.org/wiki/Multileaf_collimator