Case Study: Versatile Applications of Tantalum Tubes in Chemical Manufacturing

Introduction

Chemical manufacturing often involves the use of various materials and equipment to handle and process chemicals safely and efficiently. Tantalum tubes are one such critical component used in the chemical industry. This article is going to discuss the importance of tantalum tubes in chemical manufacturing.

[1]

[1]

Figure 1. Chemical Processing

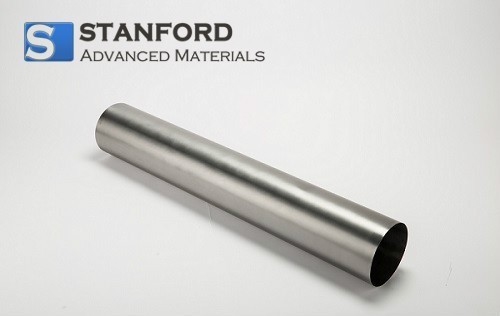

Understanding Tantalum Tubes

Tantalum Tubes are cylindrical structures made from tantalum metal, a rare and highly corrosion-resistant material. These tubes find a wide range of applications in chemical manufacturing and various other industries due to their outstanding corrosion resistance, heat resistance, purity, and compatibility with a wide range of chemicals.

Figure 2. Tantalum Tubes

Applications of Tantalum Tubes in Chemical Manufacturing

Tantalum tubes are highly sought-after in chemical manufacturing due to their exceptional resistance to corrosion and high-temperature environments. They find numerous applications in this industry, ensuring the safe handling and processing of corrosive chemicals and high-purity materials. Here are some key applications of tantalum tubes in chemical manufacturing:

1. Corrosion-Resistant Equipment: Tantalum tubes are commonly used in the construction of chemical process equipment such as heat exchangers, condensers, and reaction vessels. Tantalum's exceptional corrosion resistance makes it ideal for handling corrosive chemicals, acids, and high-temperature environments.

2. Petrochemical Industry: These tubes play a vital role in the petrochemical industry, where they are used in heat exchangers and piping systems for the production and refining of chemicals and petrochemicals. Tantalum's resistance to sulfuric acid, hydrochloric acid, and other aggressive substances is invaluable in these applications.

3. Electrolysis: Tantalum is often used as an electrode material in the production of chlorine gas and other chemicals via electrolysis. Ta tubes are utilized as electrode housings because they can withstand the harsh chemical reactions and high temperatures involved.

4. Pharmaceutical Manufacturing: They are used in pharmaceutical manufacturing for processes that involve aggressive chemicals or high-temperature reactions. They ensure the purity of pharmaceutical products and compliance with regulatory standards.

5. Semiconductor Industry: They are utilized in the semiconductor industry for applications like chemical vapor deposition (CVD) and atomic layer deposition (ALD). These tubes provide a chemically inert environment, necessary for precise semiconductor manufacturing.

Conclusion

Tantalum Tubes are invaluable components in chemical manufacturing due to their unique properties. They contribute to the safety, efficiency, and quality of chemical processes, including corrosion-resistant equipment, the petrochemical industry, electrolysis, pharmaceutical manufacturing, and the semiconductor industry. They will continue to be crucial in industries where handling corrosive substances and maintaining high-purity conditions are paramount.

Stanford Advanced Materials (SAM) offers Tantalum Tubes and Tantalum Pipes in stock at reasonable prices. A wide variety of tantalum products are also available on our website. Send us an inquiry if you are interested.

Reference:

[1] Winn, Z. (2021). Speeding up clinical trials by making drug production local [Photograph]. https://news.mit.edu/2021/snapdragon-drug-chemistry-0611