Thermocouple Wire Explained: Principle, Parts, Types, and Selection

What Is Thermocouple Wire?

Thermocouple wire is a temperature sensor made by connecting two dissimilar metals. When these metals are heated or cooled, they generate a small voltage, known as the thermoelectric effect, which is directly related to the temperature difference between the two junctions. This voltage can then be measured and converted into a temperature reading.

Thermocouple wires are widely used in industrial, scientific, and commercial applications where precise temperature monitoring is crucial. They are especially popular in processes that require high temperature control, such as in furnaces, ovens, and engines. Different types of thermocouples are used depending on the temperature range and the specific needs of the application—a topic we'll explore in more detail later.

Working Principle of Thermocouple Wire

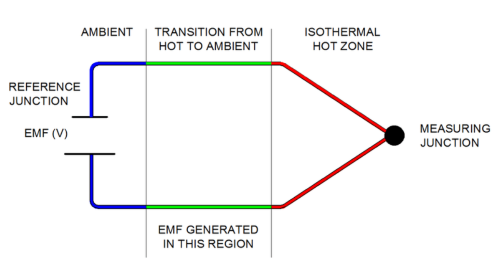

The basic principle behind thermocouple wire operation is the Seebeck effect, a phenomenon where a voltage is generated when two dissimilar metals are joined together at two junctions that are exposed to different temperatures. This process can be broken down into four key steps, from the creation of junctions to the final temperature reading, as outlined below:

- Hot and Cold Junctions: One junction of the thermocouple wire is placed at the point of measurement (the hot junction), and the other end is placed at a reference temperature (the cold junction or "reference junction").

- Voltage Generation: As the two dissimilar metals are subjected to temperature differences, a small voltage is generated at the junction. This voltage is directly related to the temperature difference between the two ends of the wire.

- Voltage Measurement: This voltage is then measured by a device (e.g., a voltmeter or thermocouple meter), and based on this voltage, the temperature of the hot junction is calculated.

- Output: The generated voltage varies depending on the types of metals used, and this is used to determine the temperature at the hot junction.

[1]

[1]

Further reading: Positive or Negative? A Beginner's Guide to Thermocouple Wire Identification

Thermocouple Wire Parts Explained

A typical thermocouple wire consists of several key components:

- Conductive Wires: The wires themselves are made from two different metals that are chosen for their thermoelectric properties. Common materials include:

- Copper (for Type T thermocouples)

- Nickel-Chromium and Nickel-Aluminum (for Type K thermocouples)

- Platinum and Rhodium (for Type R, S, and B thermocouples)

- Junctions: There are two junctions in a thermocouple circuit:

- Hot Junction: The measuring end where the temperature is being sensed.

- Cold Junction (or Reference Junction): The end of the thermocouple that is kept at a known reference temperature.

- Insulation: To protect the wires and prevent short circuits, thermocouple wires are often insulated with materials such as fiberglass, Teflon, or ceramic coatings. The insulation also ensures accurate readings by preventing the wires from coming into contact with each other.

- Protective Sheathing: Some thermocouple wires are enclosed in a protective sheath made of materials like stainless steel to guard against physical damage and chemical exposure, ensuring the wire remains intact in harsh environments.

Thermocouple Types

Thermocouple wires are specifically designed to match the type of thermocouple they are used with, as each type corresponds to a unique combination of metals and temperature ranges. Some of the most common types include:

- Type K (Chromel-Alumel): This is the most widely used thermocouple type, known for its versatility and reliability. It has a wide temperature range, typically from -270°C to 1372°C, and is commonly used in industrial applications.

- Type J (Iron-Constantan): Type J thermocouples are suitable for temperatures from -40°C to 750°C and are commonly used in general-purpose temperature measurement.

- Type T (Copper-Constantan): These are ideal for low-temperature measurements, with a range from -200°C to 350°C. They are often used in cryogenics and food processing industries.

- Type R (Platinum-Rhodium): Type R thermocouples are used for high-temperature measurements, typically between 0°C to 1600°C. They are highly accurate and are typically used in scientific applications.

- Type S (Platinum-Rhodium): Similar to Type R but with different proportions of platinum and rhodium. They are used for high-precision measurements in laboratories.

- Type B (Platinum-Rhodium): Known for measuring very high temperatures, with a range up to 1700°C. Type B is commonly used in high-temperature industrial applications, such as furnace monitoring.

- Type E (Chromel-Constantan): With a high output, Type E thermocouples are useful for low-temperature measurements, and their range extends from -200°C to 900°C.

- Type N (Nicrosil-Nisil): This thermocouple type has improved stability and resistance to oxidation, making it suitable for high-precision industrial applications. Its temperature range is -200°C to 1300°C.

How to Select Thermocouple Wire

When purchasing thermocouple wire, it is important to select the right type for your specific application. Whether you are working in industrial, research, or laboratory settings, choosing high-quality thermocouple wire ensures accuracy and longevity in temperature measurements.

- Temperature Range: Ensure that the thermocouple wire you purchase has the appropriate temperature range for your specific needs.

- Material: Choose a thermocouple wire made of materials suited for the environment in which it will be used. For instance, for high-temperature environments, choose a Type K or Type S thermocouple.

- Insulation and Sheathing: Depending on the conditions (e.g., exposure to chemicals, high humidity, or extreme temperatures), choose the appropriate insulation and protective sheathing.

- Accuracy: Ensure that the wire is rated for the level of precision required for your application.

By carefully selecting thermocouple wires that meet your application’s specific requirements, you can ensure reliable and accurate temperature measurements in any environment. Stanford Advanced Materials (SAM) provides a comprehensive selection of premium thermocouple wires, including Platinum-Rhodium (Pt-Rh), Type J, Type K, and Tungsten-Rhenium Alloy Thermocouple Wires. For detailed information on our thermocouple wire offerings and specifications, please reach out to explore our full product catalog.

Reference:

[1] Litteaur, Raymond. (2018). In Situ Verification Techniques for Multipoint Thermocouples in Pressure Vessels. 10.13140/RG.2.2.20703.30885.