The List of Support Materials for Palladium Catalysts

Palladium catalysts are essential in many chemical reactions, particularly in hydrogenation, oxidation, and carbon-carbon bond formation. The effectiveness of palladium catalysts is significantly influenced by the choice of support material. The support not only provides a large surface area for palladium dispersion but also affects the catalyst’s stability, activity, and selectivity.

Below are the key support materials used in palladium catalysis, each offering unique advantages for different applications:

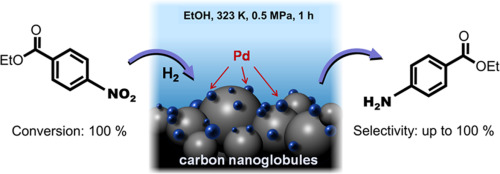

[1]

[1]

Fig. 1 Carbon-based Palladium Catalysts

1. Carbon-based Supports

- Activated Carbon (Pd/C): As one of the most common support materials, activated carbon provides a high surface area for palladium dispersion. Pd/C is particularly effective in hydrogenation reactions and fine chemical synthesis. The high porosity and stability of carbon contribute to the catalyst's reusability.

- Carbon Nanotubes (Pd/CNT): Carbon nanotubes offer an even greater surface area and excellent conductivity compared to activated carbon. They are often used in advanced applications like fuel cells and sensors due to their high thermal and chemical stability.

2. Alumina (Al2O3)

- Palladium on Alumina (Pd/Al2O3): Alumina is a widely used support due to its high thermal stability and ability to withstand high-temperature reactions. Pd/Al2O3 is commonly used in catalytic reforming and dehydrogenation processes, where high-temperature resistance is crucial.

- Gamma-Alumina: This form of alumina is known for its high surface area and tunable acidic properties, which can be tailored for specific reactions, such as selective oxidation or hydrogenation.

3. Silica (SiO2)

- Palladium on Silica (Pd/SiO2): Silica offers a high surface area and is often used in reactions requiring a neutral support. Pd/SiO2 is particularly effective in reactions like hydrogenation and dehydrogenation of organic compounds. Silica’s stability and low acidity make it suitable for processes where acidic support interactions are undesirable.

4. Zeolites

- Palladium on Zeolites (Pd/Zeolite): Zeolites, with their highly ordered porous structure, provide unique catalytic properties due to their acid-base characteristics and shape selectivity. Pd/zeolite catalysts are often used in reactions like selective hydrogenation and hydrocracking, where size and shape of the pores can direct the catalytic activity.

- Hierarchical Zeolites: These zeolites have both micropores and mesopores, offering improved accessibility for larger molecules and better stability, particularly in reactions like selective oxidation.

5. Metal Oxides

- Palladium on Titanium Dioxide (Pd/TiO2): Titanium dioxide is a stable and versatile support material. Pd/TiO2 is used in reactions like hydrogenation and oxidation, where the titania support plays a role in electron transfer and photocatalysis, particularly under UV light.

- Palladium on Zirconia (Pd/ZrO2): Zirconia is used for its high stability at high temperatures. Pd/ZrO2 is effective in reactions such as selective hydrogenation and oxidation, where both palladium's catalytic properties and zirconia’s thermal stability are essential.

6. Magnesia (MgO)

- Palladium on Magnesia (Pd/MgO): Magnesium oxide supports palladium in reactions where both basic and thermal properties are important. Pd/MgO catalysts are particularly useful in catalytic hydrogenation and reforming processes.

7. Graphene

- Palladium on Graphene (Pd/Graphene): Graphene, with its high surface area, electrical conductivity, and mechanical strength, is increasingly being used as a support for palladium. Pd/graphene catalysts are highly effective in hydrogenation and fuel cell applications, offering enhanced electronic properties and activity.

8. Polymeric Supports

- Palladium on Polymers (Pd/Polymer): Polymers such as polystyrene or polyethylene can be used to support palladium in specialized reactions, often in liquid-phase catalysis. These supports can offer unique selectivity and stability in catalytic processes involving organic solvents.

9. Metal Supports

- Palladium on Gold (Pd/Au): In some cases, gold is used as a support for palladium due to its unique electronic properties. Pd/Au catalysts are particularly effective in certain types of oxidation and hydrogenation reactions, where the gold surface enhances palladium’s activity.

- Palladium on Copper (Pd/Cu): Copper supports palladium in reactions that require a balance of oxidation and reduction properties. Pd/Cu catalysts are often used in processes such as hydrogenation and selective oxidation.

Palladium-Based Catalysts on Various Supports

Support Material | Examples | Key Properties | Applications |

Carbon-Based Supports | Pd/C, Pd/CNT | High surface area, stability, conductivity (CNT), porosity | Hydrogenation, fine chemical synthesis, fuel cells, sensors |

Alumina (Al2O3) | Pd/Al2O3, Gamma-Alumina | High thermal stability, tunable acidic properties | Catalytic reforming, dehydrogenation, selective oxidation |

Silica (SiO2) | Pd/SiO2 | Neutral support, stability, low acidity | Hydrogenation, dehydrogenation of organic compounds |

Zeolites | Pd/Zeolite, Hierarchical Zeolites | Ordered porous structure, acid-base characteristics, shape selectivity | Selective hydrogenation, hydrocracking, selective oxidation |

Metal Oxides | Pd/TiO2, Pd/ZrO2 | Stability, electron transfer (TiO2), high-temperature stability (ZrO2) | Hydrogenation, oxidation, photocatalysis |

Magnesia (MgO) | Pd/MgO | Basic properties, thermal stability | Hydrogenation, reforming processes |

Graphene | Pd/Graphene | High surface area, electrical conductivity, mechanical strength | Hydrogenation, fuel cells |

Polymeric Supports | Pd/Polymer | Selectivity, stability in organic solvents | Liquid-phase catalysis |

Metal Supports | Pd/Au, Pd/Cu | Unique electronic properties (Au), balanced redox properties (Cu) | Oxidation, hydrogenation, selective oxidation |

This table highlights the diverse support materials used for palladium-based catalysts, their distinctive properties, and their respective application areas. For more information, please check Stanford Advanced Materials (SAM).

Conclusion

The choice of support material for palladium catalysts plays a critical role in determining the catalyst's effectiveness, stability, and selectivity in various reactions. By optimizing the interaction between palladium and its support, researchers and engineers can enhance reaction efficiency and expand the scope of palladium catalysis in modern chemical processes.

Reference:

[1] Roman M. Mironenko, Olga B. Belskaya, Tatiana I. Gulyaeva, Mikhail V. Trenikhin, Vladimir A. Likholobov, Palladium nanoparticles supported on carbon nanoglobules as efficient catalysts for obtaining benzocaine via selective hydrogenation of ethyl 4-nitrobenzoate, Catalysis Communications, Volume 114, 2018, Pages 46-50, ISSN 1566-7367, https://doi.org/10.1016/j.catcom.2018.06.002.