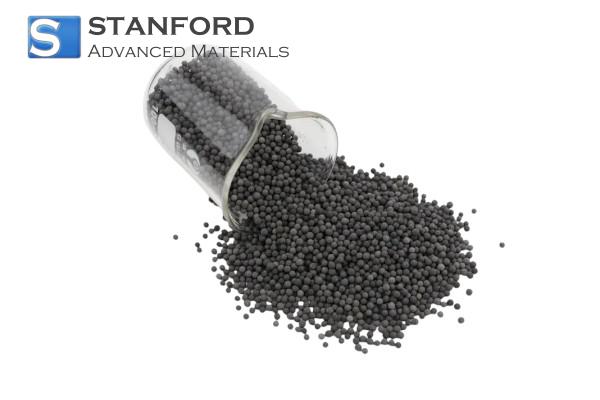

CY1874 Palladium on Carbon Catalyst (Pd/C)

| Catalog No. | CY1874 |

| Particle Size | 28-34 μm |

| Product Name | Palladium Catalyst |

| Metal Content | 48~65 m2/g |

| Purity | Pd 0.5%,1%,5%,10%,15%,20% |

Palladium on Carbon is a catalyst prepared by supporting metal palladium powder on activated carbon, and its main function is catalytic hydrogenation of unsaturated hydrocarbons or CO. Stanford Advanced Materials (SAM) offers Palladium on Carbon Catalyst suits for the production of pharmaceutical intermediates such as aniline and succinic acid. Feel free to contact us for custom product information.

Related products: Pt on Carbon Catalyst.

Palladium on Carbon Catalyst Description

Palladium on Carbon is a high-performance catalyst prepared by dispersing metal palladium powder onto activated carbon with a high surface area and optimal pore distribution. Primarily utilized for the catalytic hydrogenation of unsaturated hydrocarbons and carbon monoxide (CO), this catalyst offers exceptional hydrogenation reducibility and selectivity.

Key Features:

- High Purity Palladium: Our Palladium on Carbon Catalyst (Pd/C) is meticulously prepared with the highest purity palladium, ensuring exceptional catalytic performance in a wide range of chemical reactions.

- Versatile Catalytic Power: Leverage the unique catalytic capabilities of palladium for reactions including hydrogenation, dehydrogenation, oxidation, and more.

- Uniform Particle Size: Our finely engineered catalyst exhibits a consistent particle size distribution, ensuring dependable and reproducible results in your experiments.

- High Surface Area: The optimized surface area of our Pd/C catalyst promotes efficient reactant contact, leading to improved yields and faster reaction kinetics.

- Stability and Longevity: Engineered for long-term stability, our Pd/C catalyst resists degradation, delivering consistent performance throughout extended reactions.

- Customizable Options: We offer various loadings and formulations to cater to your specific requirements, enabling tailored solutions for your unique applications.

Palladium on Carbon Catalyst Specifications

|

Specific surface area (m2/g) |

≥930 |

|

Metal surface area (m2/g) |

48~65 |

|

Mean diameter of carrier (μm) |

28~34 |

|

Impurity (%) |

≤0.3 |

|

Grain intensity |

≥90 |

|

Water content (%) |

0.1 |

|

Main reaction yield (%) |

90-99 |

|

Ash content (m) |

≥5 |

Palladium carbon catalyst |

Palladium content (%) |

1.0±0.02 |

3.0±0.02 |

5.0±0.02 |

|

Index name |

Φ1.5~5.0 |

Φ1.5~5.0 |

Φ1.5~5.0 |

|

|

Abrasion rate (%) |

≤ 0.25 |

≤ 0.25 |

≤ 0.25 |

|

|

Bulk density (g/ml) |

≥ 0.65 |

≥ 0.65 |

≥ 0.65 |

|

|

Static water absorption (%) |

≥ 20.0 |

≥ 20.0 |

≥ 20.0 |

|

|

Static normal hexane absorption (%) |

≥ 12.0 |

≥ 12.0 |

≥ 12.0 |

|

|

Specific surface area (m2/g) |

≥ 100 |

≥ 100 |

≥ 100 |

|

|

Compressive strength point contact strength (N/grain) |

≥ 50 |

≥ 55 |

≥ 55 |

|

|

Variation coefficient of resistance to crushing |

≤ 0.3 |

≤ 0.3 |

≤ 0.3 |

|

|

Granularity (%) |

≥ 96 |

≥ 96 |

≥ 96 |

|

|

Water content of packed product (%) |

≤ 1.5 |

≤ 1.5 |

≤ 1.5 |

Palladium on Carbon Catalyst Applications

- Hydrogenation of alkynes to alkanes

- Aromatic aldehyde hydrogenation to alcohol

- Aromatic ketone hydrogenated carbonyl

- Hydrogenation of aromatic ketone to alcohol

- Aromatic ketone reduction to form hydrocarbons

- Production of pharmaceutical intermediates such as aniline and succinic acid

Palladium on Carbon Catalyst Packaging

Our Palladium on Carbon Catalyst within 25g is loaded into the glass bottle. We also offer customized packing. The product is tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Frequently Asked Questions (FAQ)

1. What are the main advantages of Palladium on Carbon Catalyst?

Palladium on Carbon Catalyst offers high catalytic activity and excellent selectivity, enabling efficient hydrogenation reactions with lower palladium usage. It is highly stable, reusable, and easy to recover and regenerate, ensuring long-term performance in industrial applications.

2. How should Palladium on Carbon Catalyst be stored and handled?

Store the catalyst in a cool, dry place away from direct sunlight and moisture. When handling, wear appropriate protective equipment such as gloves and safety goggles to prevent contact and inhalation. Ensure containers are sealed properly to avoid contamination and performance degradation.

3. What types of reactions is Palladium on Carbon Catalyst suitable for?

It is primarily used for the hydrogenation of unsaturated hydrocarbons and carbon monoxide. The catalyst performs well in petroleum refining, pharmaceuticals, electronics, flavors and fragrances, and dye manufacturing, efficiently converting various organic compounds to enhance product quality and production efficiency.

4. How many times can Palladium on Carbon Catalyst be reused?

With proper regeneration and maintenance, the catalyst can be reused multiple times. After each use, recover and clean the catalyst appropriately to maintain its activity and selectivity, extending its lifespan and reducing production costs.

5. How does Palladium on Carbon Catalyst compare to other palladium-based catalysts?

Compared to other palladium catalysts, Palladium on Carbon Catalyst has a higher surface area and better palladium dispersion, resulting in higher catalytic efficiency. It requires lower palladium loading, reducing overall costs, and offers superior stability and reusability.

6. Why Choose Our Pd/C Catalyst?

- Quality Assurance: We uphold stringent quality control standards to guarantee the purity and consistency of our Pd/C catalyst.

- Expert Support: Our team of experienced chemists and technical experts is ready to assist you with any questions or challenges you may encounter.

- Customization: Tailor-made solutions to meet your specific project requirements, ensuring optimal results.

- Competitive Pricing: We offer competitive pricing for top-quality Pd/C catalysts, making it accessible for research and industrial applications.

- Global Reach: We ship our products worldwide, ensuring that our catalyst reaches researchers and industries globally.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!