Tungsten-Rhenium Alloy: A Comprehensive Guide

Introduction

Tungsten-Rhenium (W-Re) alloys are high-performance materials combining the exceptional properties of tungsten (W) and rhenium (Re). These alloys are renowned for their remarkable high-temperature stability, mechanical strength, and resistance to harsh environments. This comprehensive guide briefs the properties, production processes, applications, and future potential of Tungsten-Rhenium alloys.

Properties of Tungsten-Rhenium Alloys

Tungsten-Rhenium (W-Re) alloys are distinguished by their exceptional properties, which combine the strengths of tungsten and rhenium.

- High Melting Point: Tungsten has a melting point of approximately 3422°C, one of the highest among metals. Rhenium’s melting point is also exceptionally high at around 3180°C. The resulting alloy maintains a high melting point, making it suitable for applications involving extreme temperatures.

- Mechanical Strength and Ductility: While tungsten is known for its strength, it can be quite brittle. The addition of rhenium significantly enhances the ductility of the alloy, reducing brittleness and improving its mechanical performance under stress.

- Thermal Stability: Tungsten-Rhenium alloys maintain their structural integrity and strength at high temperatures, which is critical for applications in high-temperature environments such as aerospace and industrial processes.

- Corrosion and Oxidation Resistance: The alloys exhibit excellent resistance to corrosion and oxidation, even at elevated temperatures. This makes them ideal for use in chemically aggressive environments.

- Electrical Conductivity: The alloy’s electrical conductivity is superior to that of pure tungsten, making it valuable in electronic and electrical applications.

Production Processes

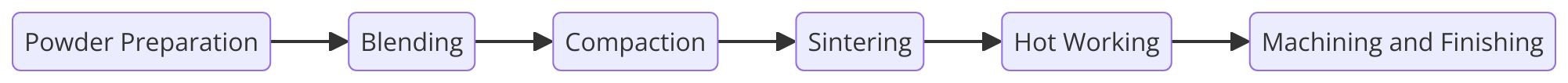

The production of Tungsten-Rhenium alloys typically involves powder metallurgy techniques. Here are the key steps in the process:

- Powder Preparation: High-purity tungsten and rhenium powders are prepared. These powders must be fine and uniform to ensure the quality of the final alloy.

- Blending: The tungsten and rhenium powders are thoroughly blended in specific ratios, typically ranging from 3% to 26% rhenium by weight, depending on the desired properties of the final alloy.

- Compaction: The blended powder is then compacted into a desired shape using high pressure. This step helps in achieving the necessary density and uniformity.

- Sintering: The compacted powder is sintered at high temperatures in a controlled atmosphere. Sintering helps in bonding the particles together and enhances the mechanical properties of the alloy.

- Hot Working: Post-sintering, the material may undergo hot working processes such as forging or rolling to further refine its microstructure and mechanical properties.

- Machining and Finishing: The sintered and worked alloy is then machined and finished to the required specifications for its intended application.

Applications of Tungsten-Rhenium Alloys

The unique combination of properties offered by Tungsten-Rhenium alloys makes them suitable for a wide range of applications across various industries:

1. Aerospace and Defense: These alloys are extensively used in aerospace and defense sectors for components that must withstand extreme temperatures and mechanical stress. Applications include rocket nozzles, thruster components, and thermocouples used in propulsion systems.

2. Electronics: Tungsten-Rhenium alloys are used in thermocouples, which measure high temperatures in industrial processes. They are also employed in electrical contacts, filaments, and X-ray tubes due to their superior electrical conductivity and thermal stability.

3. Medical Devices: In the medical field, Tungsten-Rhenium alloys are used for radiation shielding, collimators, and high-density applications in medical imaging and therapeutic devices.

4. Industrial Processes: The alloys are ideal for high-temperature furnaces, hot zone components, and other industrial equipment subjected to extreme conditions. They are also used in the glass and metalworking industries for tooling and dies.

5. Nuclear Applications: Due to their excellent resistance to radiation and high temperatures, Tungsten-Rhenium alloys are utilized in nuclear reactors, radiation shielding, and other nuclear technologies.

Future Potential and Developments

The ongoing advancements in material science and engineering are paving the way for new and enhanced applications of Tungsten-Rhenium alloys. Research is focused on optimizing the properties of these alloys to meet the ever-increasing demands of modern technology and industry. Areas of potential development include:

- Enhanced Alloy Compositions: Researchers are exploring new compositions and processing techniques to further improve the mechanical properties, thermal stability, and corrosion resistance of Tungsten-Rhenium alloys.

- Additive Manufacturing: The application of additive manufacturing (3D printing) techniques to Tungsten-Rhenium alloys is a promising area. This could enable the production of complex geometries and customized components with high precision and minimal waste.

- Advanced Coatings: The development of advanced coatings and surface treatments could further enhance the performance of Tungsten-Rhenium components in harsh environments.

- Nanostructured Alloys: The incorporation of nanotechnology to create nanostructured Tungsten-Rhenium alloys could lead to materials with superior properties, including increased strength and enhanced thermal and electrical performance.

Conclusion

Tungsten-Rhenium alloys represent a remarkable class of materials with unique properties that make them indispensable in high-temperature, high-stress, and corrosive environments. Their applications span across critical industries such as aerospace, electronics, medical devices, and nuclear technology. As research and development continue to advance, Tungsten-Rhenium alloys are poised to play an even more significant role in the future of material science and engineering, driving innovation and enabling new technological breakthroughs.

Stanford Advanced Materials (SAM) boasts extensive expertise in the manufacturing and supply of high-quality Tungsten Rhenium Alloy Products. With years of experience in the industry, SAM guarantees that customers receive reliable Tungsten Rhenium Alloy Products tailored to meet diverse and demanding applications. Send us an inquiry if you are interested.