Innovations in Optics: The Role of GGG, SGGG, and NGG Garnet Boules

1 Preface

The full-scale construction of 5G networks is bringing new opportunities to the optical fibre communications market. Optical fibre is the only material that provides the necessary high data transmission rates. While the demand for optical fibre is surging due to 5G networks, the demand for fibre optic isolators is also on the rise. Fibre optic isolators are used in combination with bait-doped fibre amplifiers to increase the maximum gain and reduce the noise index. In the rapid development of dense wavelength division multiplexing (DWDM) fibre optic communication, high-speed and high-capacity systems play a significant role. Optical isolators are especially important in this context.

Gadolinium Gallium Garnet (GGG), Scandium Gadolinium Gallium Garnet (SGGG) and Neodymium Gallium Garnet (NGG) are widely used in various magneto-optical devices due to their excellent magneto-optical properties and become a rising star in the field of optical materials.

Picture 1 Fibre optic

2 GGG

2.1 Introduction

Gadolinium Gallium Garnet (GGG, formula Gd3Ga5O12) is a garnet-like synthetic crystalline material that is usually colourless. It has a cubic crystal lattice, a density of 7.08 g/cm3, and a Mohs hardness of 6.5 and 7.5. As an important raw material for optical devices, GGG has some unique properties. It has a relatively high refractive index. At the same time, it has good transparency in the visible spectral range. This allows light to pass through and maintain its original optical properties. It is ideal for the preparation of optical devices such as high-refractive index lenses, optical components and laser devices. It also exhibits several nonlinear optical effects, such as the optical Kerr effect and the self-focusing effect. GGG has a relatively low thermal conductivity, and its excellent heat dissipation makes it ideal for use in optical devices as well as substrates. Most importantly, GGG has excellent magneto-optical properties, which are characterised by the Faraday spin effect. This property has led to a wide range of applications in magneto-optical devices, such as magneto-optical storage devices and magneto-optical deflectors.

Picture 2 Flaky GGG crystals

2.2 Characters

Transistors and integrated circuits are fabricated on the surface of a semiconductor sheet, which in this case is the substrate (chip). The semiconductor substrate plays a role not only in electrical properties but also in mechanical support.

As a substrate material, GGG has characteristics that are very suitable for substrate materials:

1. Structural match between substrate and epitaxial film: Epitaxial materials and substrate materials have the same or similar crystal structure, small lattice constant mismatch, good crystalline properties, and low defect density. The lattice constant and coefficient of thermal expansion of GGG single crystals are matched with YIG. Therefore, GGG single crystal is considered to be a suitable substrate material for YIG and YIG-like magneto-optical epitaxial films. These YIG and YIG-like materials have a wide range of applications in the field of optical isolators, optical waveguides and integrated optics.

2. Matching of thermal expansion coefficient between substrate and epitaxial film: Matching of thermal expansion coefficient is very important. The difference between epitaxial film and substrate material in thermal expansion coefficient is too large not only may make the epitaxial film quality decline, but also in the working process of the device, due to the heat caused by the damage of the device.

3. The chemical stability of the substrate and epitaxial film match: The substrate material should have good chemical stability, and protect the epitaxial film while maintaining its stability and non-decomposition during processing.

4. The ease of preparation and cost of materials: To be put into mass production, the preparation of the substrate material requires a simple process and as low a cost as possible.

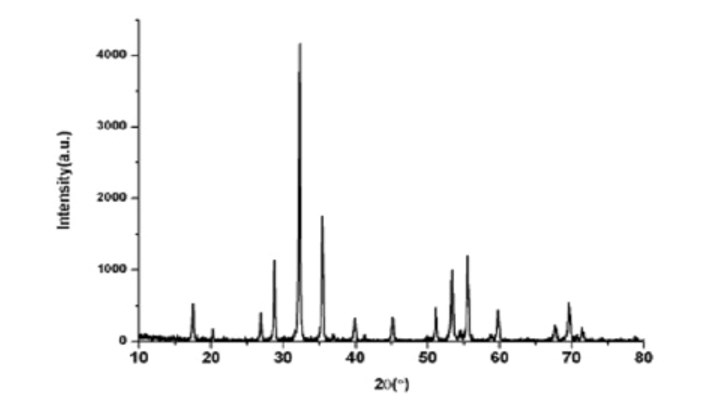

Picture 3 XRD pattern of GGG at 1000°C

2.3 Preparation

The vast majority of magnetic bubble memories are prepared on Gadolinium Gallium Garnet (GGG) substrates. These substrates serve not only as carriers but also as nuclei for epitaxial growth of magnetic storage layers. Any defect in the substrate structure will be reproduced in the epitaxial layer, so the substrate must be very uniform. Thus, the preparation process technology of GGG itself must be very perfect to ensure its quality. The most common method of preparation of GGGs is the tensile method, and two of the most important aspects of the tensile preparation process are the control of temperature and rate.

1. Temperature control: The temperature control of the melt is the key to the crystal growth process of the tensile method. The temperature distribution in the melt is required to maintain the melting point temperature at the solid-liquid interface, to ensure that the melt around the seed crystal has a certain degree of subcooling, and the rest of the melt remains superheated. In this way, it ensures that the melt does not produce other nuclei, atoms or molecules at the interface according to the structure of the seed crystal arranged into a single crystal. To maintain a certain degree of subcooling, the growth interface must constantly move towards lower temperatures away from the isothermal surface of the solidification point for the crystals to grow. In addition, the temperature of the melt is usually much higher than room temperature, to keep the melt at its proper temperature, but also by the heater must also have a continuous supply of heat.

2. Lifting rate: The rate of lifting determines the crystal growth rate and quality. With appropriate rotational speed, the melt can produce good mixing, and reduce the radial temperature gradient, to prevent the components of the purpose of overcooling. The general lifting rate is 6-15mm per hour.

In addition, due to the growth of the GGG material itself, foggy white particles are sometimes produced in the crystals, which affects optical use. The related technical reasons and improvement options are also being explored.

Picture 4 Sometimes foggy white spots appear in GGG crystals

2.4 Applications (in refrigeration)

Magnetic materials undergo a change in the direction of their magnetic moment in an applied magnetic field. This process is accompanied by a change in magnetic entropy, namely the entropy change caused by the reorientation of the magnetic moment in the external magnetic field. Heat exchange occurs when magnetic materials undergo magnetic entropy change in a magnetic field. By designing a magnetic refrigeration system, it is possible to cool down an object while absorbing heat. In the magnetic refrigeration industry, GGG has been successfully applied in the temperature region below 20K for market He II flow as well as helium-nitrogen liquefaction pre-stage refrigeration.

Picture 5 Columnar GGG crystals

3 SGGG&NGG

3.1 SGGG

Scandium Gadolinium Gallium Garnet (SGGG, formula Gd3Sc2Ga3O12) crystals are crystals obtained by substituting Sc3+ for part of Ga3+ in GGG crystals, which are similar in structure and appearance and are produced by the same method. GSGG has some advantages:

1. Similar to GGG, the high-quality coreless GSGG crystals are easy to grow and can avoid the defects of impurities and stress caused by the growth of small surfaces.

2. Sc-containing garnet has higher thermal conductivity and stable physicochemical properties, possesses higher heat dissipation efficiency, and effectively avoids problems caused by surface overheating.

Materials | GGG | SGGG |

Chemical Formula | Gd3Ga5O12 | Substituted GGG |

Lattice Constant | 12.383 Å | 12.497 Å |

Density(g/cm3) | 7.13 | 7.09 |

Melting Point(℃) | 1725 | 1730 |

Mohs Hardness | 8.0 | 7.5 |

Refractive Index | 1.954 at 1064nm | 1.954 at 1064nm |

Growth Method | Czochralski | Czochralski |

Table 1 Comparison of the properties of GGG and SGGG

3.2 NGG

Neodymium Gallium Garnet (NGG) crystals are crystals obtained by substituting Nd3+ for part of Ga3+ in GGG crystals. Its advantages are mainly reflected in:

1. The crystal is relatively easy to grow, and the crystal growth rate can reach 5 mm/h.

2. The crystal can be grown at a flat interface without stress concentration and with few impurities, making it easy to prepare large-size slats for high-power crystal applications.

3. Nd in Yttrium Aluminium Garnet (YAG) crystals has a partition coefficient of 0.1-0.2, while in GGG crystals the partition coefficient of Nd is higher up to 0.52, which is conducive to the preparation of high-concentration doped laser crystals, thus increasing the pump power [1].

4. Compared with the laser gain medium neodymium glass, Nd: GGG crystals have higher mechanical strength and higher thermal conductivity, which enables the cooling of the crystals in a shorter time.

5. The homomorphic substitution of Nd3+ for Gd3+ effectively avoids the luminescence fragmentation in the upper energy level of the Nd3+ laser [2].

6. The laser efficiency of Nd: GGG crystals is twice as high as that of neodymium glass, a commonly used high-power laser gain medium, and can be used as a laser working medium in short-range strategic laser weapons with a power of up to 100 kW [3,4].

Materials | GGG | SGGG | NGG |

Chemical Formula | Gd3Ga5O12 | Substituted GGG | Nd3Ga5O12 |

Lattice Constant | 12.383 Å | 12.497 Å | 12.509 Å |

Diameter | 1’’,2’’,3’’ or 4’’ | 1’’,2’’,3’’ or 4’’ | 1’’ or 2’’ |

Density(g/cm3) | 7.13 | 7.09 | ~7.4 |

Refractive Index | 1.954 at 1064nm | 1.954 at 1064nm | ~1.97 at 1064nm |

Orientation | (111) (110) (100) | (111) (110) (100) | (111) |

Table 2 Comparison of the properties of GGG, SGGG and NGG

4 Conclusion

GGG, SGGG and NGG are widely used in laser technology, optical devices, magnetic applications and other high-tech fields due to their superior optical properties. GGG, as the most widely researched and applied material, has been used in a variety of applications in the fields of laser resonance cavities, magneto-optical devices laser crystals, etc.; SGGG and NGG have superior aspects on their original properties and are waiting for more applications to be explored due to doping of scandium and neodymium with two kinds of rare earth elements. SGGG and NGG, due to the doping of two rare earth elements, scandium and neodymium, have superior aspects to the original properties of GGG and are waiting for more applications to be explored.

References

[1]ZIMIK K,CHAUHAN R R,KUMAR R,et a1.Study on the growth of Nd3+:Gd3Ga5O12(Nd: GGG) crystal by the czochralski technique under different gas flow rates and using different crucible sizes for flat interface growth[J].JournaI of CrystaI Growth,2013,363(3):76—79.