- Products

- Categories

- Blog

- Podcast

- Application

- Document

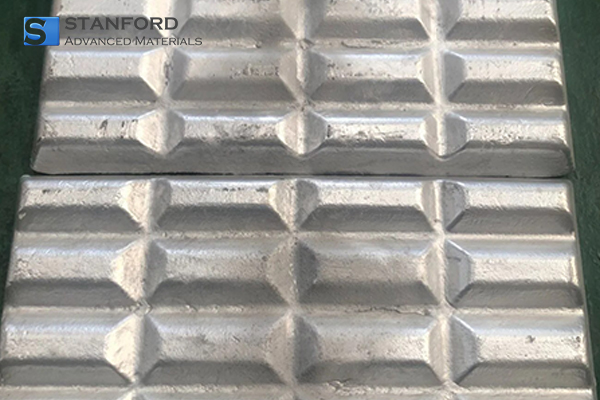

TA4355 Spherical TaNb Alloy (Ta40Nb) Powder

| Catalog No. | TA4355 |

| Compositions | Ta, Nb |

| Shape | Spherical Powder |

| Purity | 99.5% |

| Size | 15-45μm |

Spherical TaNb Alloy (Ta40Nb) Powder has long been known to be the most corrosive resistant metal for use in hot acidic environments like hydrochloric, sulfuric, nitric, formic, and acetic acid. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Spherical TaNb Alloy (Ta40Nb) Powder.

Related products: Spherical TaW Powder (TA2.5W), Spherical TaW Powder (TA7.5W), Spherical TaW Powder (TA10W)

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!