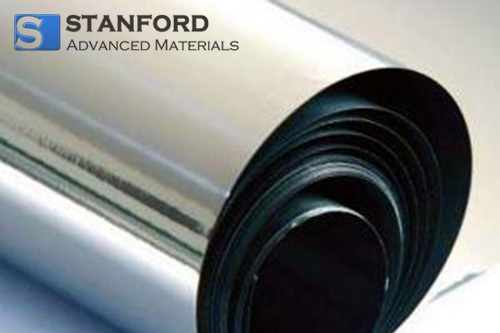

TA0002 Tantalum Foil, Tantalum Strip

| Catalog No. | TA0002 |

| Material | R05200 R05400 |

| Standard | ASTM B708-98 |

| Purity | ≥99.9% or 99.95% |

Stanford Advanced Materials (SAM) offers Tantalum Foils and Strips with a focus on high purity and competitive pricing. Backed by extensive expertise, our products meet stringent standards, ensuring a blend of precision and affordability. Explore our range for reliable sourcing of Tantalum materials, reflecting our commitment to quality and cost-effectiveness.

Related products: Tantalum Tungsten Disc, Ta Sheet/Ta Plate, Ta Tube/Ta Pipe, Ta Capillary, Ta Wire, and Ta Bar/Ta Rod.

Tantalum Foil & Tantalum Strip Description

Tantalum Foils and Strips, available at Stanford Advanced Materials (SAM), exhibit exceptional properties essential for various industrial applications. Renowned for their high melting point, superior corrosion resistance, and excellent conductivity, these materials are indispensable in fields such as electronics, aerospace, and chemical processing. The foils and strips, crafted with precision, boast high purity levels and offer optimal performance under challenging conditions. SAM's commitment to quality ensures that these Tantalum products meet stringent standards, providing customers with reliable solutions for their specific requirements. Explore the versatility and reliability of Tantalum Foils and Strips at SAM for cutting-edge applications.

Tantalum Foil & Tantalum Strip Specification

Condition: Annealed

|

Product Name |

Thickness (mm) |

Width (mm) |

Length (mm) |

Material |

Standard |

Purity |

|

Tantalum Foil |

0.03-0.07 |

30-200 |

>50 |

UNS R05200, UNS R05400 |

ASTM B708-98 |

≥99.9% or 99.95% |

|

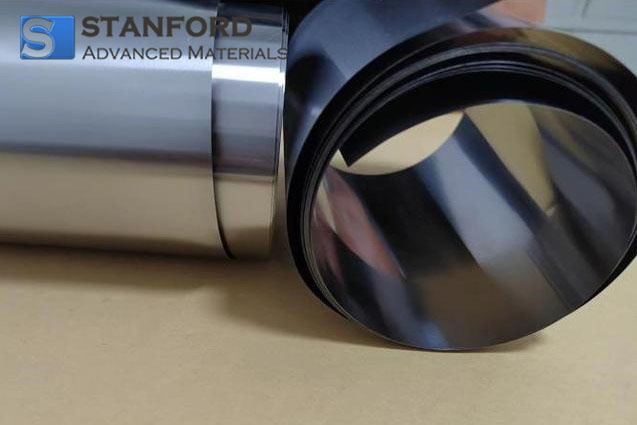

Tantalum Strip |

0.03 |

1-1.5 |

Up to 50000 |

UNS R05200, UNS R05400 |

ASTM B708-98 |

≥99.9% or 99.95% |

If you require tantalum in thicknesses greater than those shown here, see tantalum sheet.

Chemical Composition

|

Element |

R05200 (%,Max) |

R05400 (%,Max) |

|

C |

0.01 |

0.01 |

|

O |

0.015 |

0.03 |

|

N |

0.01 |

0.01 |

|

H |

0.0015 |

0.0015 |

|

Fe |

0.01 |

0.01 |

|

Mo |

0.02 |

0.02 |

|

Nb |

0.1 |

0.1 |

|

Ni |

0.01 |

0.01 |

|

Si |

0.005 |

0.005 |

|

Ti |

0.01 |

0.01 |

|

W |

0.05 |

0.05 |

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Foil & Tantalum Strip Applications

1. Electronics: Tantalum foils are widely employed in the production of capacitors for electronic devices. Their high capacitance and stability make them ideal for use in mobile phones, computers, and other electronic components.

2. Aerospace: Tantalum's high melting point and corrosion resistance make it suitable for aerospace applications. It is utilized in manufacturing parts for aircraft engines, rockets, and other high-temperature and harsh environment components.

3. Chemical Processing: Tantalum's excellent corrosion resistance makes it valuable in the chemical industry. It is used to fabricate equipment such as reaction vessels, heat exchangers, and pipes for handling corrosive substances.

4. Medical Devices: Tantalum is employed in certain medical devices, including implants and instruments, due to its biocompatibility and resistance to bodily fluids.

5. Nuclear Applications: Tantalum's ability to withstand radiation makes it suitable for use in nuclear reactors and related applications.

Tantalum Foil & Tantalum Strip Packaging

Our tantalum foil and tantalum strip are carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Material Safety Data Sheet (MSDS) for your reference!

FAQs

- Tantalum Foil & Tantalum Strip FAQs:

1 What are the properties of Tantalum foil? Tantalum foil has excellent corrosion resistance, especially to strong acids like sulfuric acid and hydrochloric acid. It also boasts a high melting point of 3,017°C, making it ideal for high-temperature applications. Tantalum is non-reactive, durable, and maintains its form under extreme conditions.

2 How thick is Tantalum foil? Tantalum foil can come in a wide range of thicknesses, typically ranging from 0.001 inches to 0.125 inches (0.025 mm to 3.175 mm). Custom thicknesses can be manufactured to meet specific industry requirements.

3 How is Tantalum foil produced? Tantalum foil is typically produced by rolling or drawing the metal into thin sheets. The process often starts with a slab or ingot of tantalum metal, which is heated and then passed through rollers or drawing dies to achieve the desired thickness.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!