TA0009 Tantalum Crucible (Ta Crucible)

| Catalog No. | TA0009 |

| Material | R05200 R05400 |

| Size | 10-500mm OD x 10-600mm L |

| Standard | ASTM B708 |

| Purity | ≥99.95% |

| Density | 16.6 g/cc |

| Surface | Finish turning, Polishing |

| MSDS/SDS |

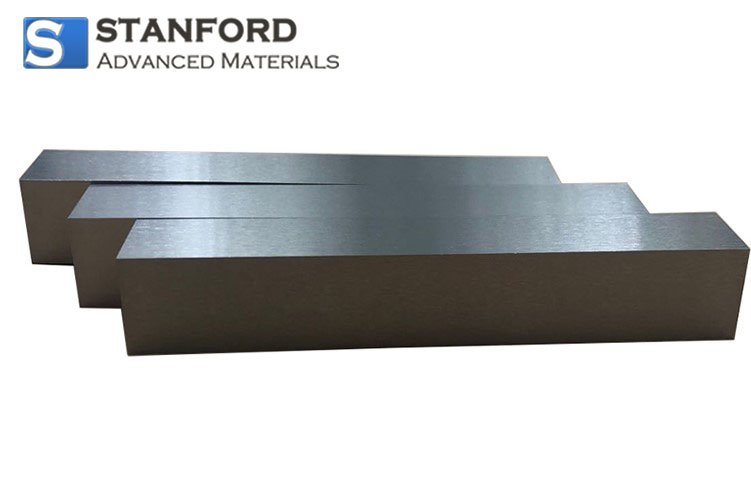

Tantalum crucibles of a variety of dimensions can be bought at Stanford Advanced Materials (SAM). SAM is a trusted-worthy supplier of various tantalum products. Custom tailoring is available upon request.

Other tantalum products: tantalum tube/tantalum pipe, tantalum wire, tantalum foil/tantalum strip, tantalum sheet/tantalum plate, etc.

Tantalum Crucible Description

Tantalum Crucible is a high-temperature-resistant container made of tantalum metal. It is mainly used to hold materials in high-temperature furnaces for melting, sintering, evaporation, and other process operations at high temperatures. Tantalum Crucible has the properties of high melting point, high hardness, low coefficient of thermal expansion good corrosion resistance, etc. The crucible's high melting point and hardness make it suitable for handling a wide range of materials, including refractory materials that require high-temperature processing. It can maintain stable performance at high temperatures and has good corrosion resistance to various acids, alkalis and salts, ensuring the purity and safety of the materials it processes. Its superior performance and durability make it a valuable addition to any high-temperature workflow.

Stanford Advanced Materials (SAM) is a trust-worthy supplier of tantalum crucibles, that has over two decades of experience in the manufacture and sale of tantalum crucibles and other tantalum products.

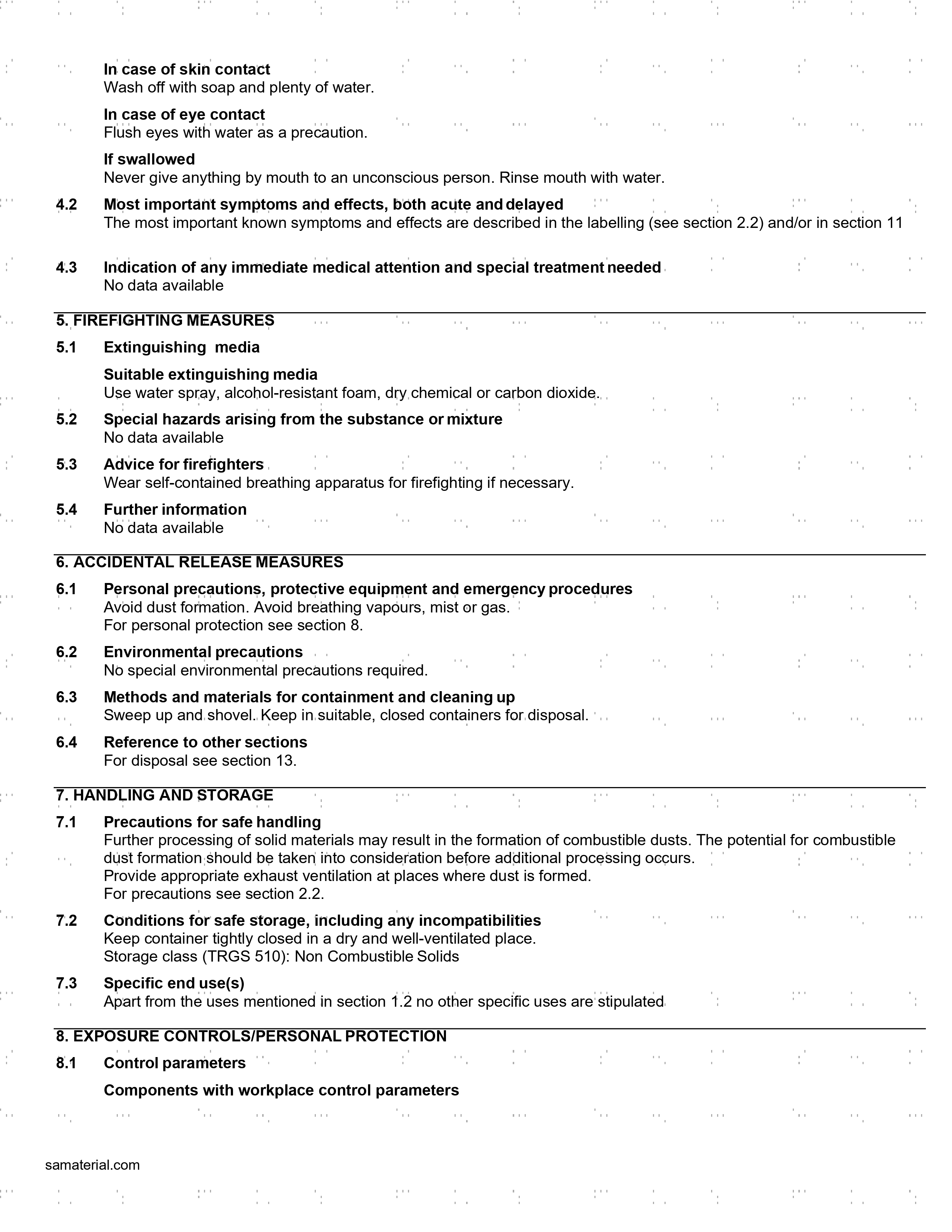

Tantalum Crucible Specifications

| Item Ce | CAP (mL) | OD (mm) |

ID (mm) |

DPT (mm) |

Tolerances |

| TA00891000 | 1000 | 127 | 125.5 | 89 | OD: ±10 % ID: ±10 % DPT: ±10 % |

| TA00450100 | 100 | 59 | 58 | 45 | |

| TA00410075 | 75 | 51 | 50 | 41 | |

| TA00410055 | 55 | 47 | 46 | 41 | |

| TA00340045 | 45 | 46 | 45 | 34 | |

| TA00290035 | 35 | 46 | 45 | 29 | |

| TA00220025 | 25 | 45 | 44 | 22 | |

| TA00290020 | 20 | 33 | 32 | 29 | |

| TA00220015 | 15 | 33 | 32 | 22 | |

| TA00220010 | 10 | 27 | 26 | 22 | |

| TA00180005 | 5 | 21 | 20 | 18 |

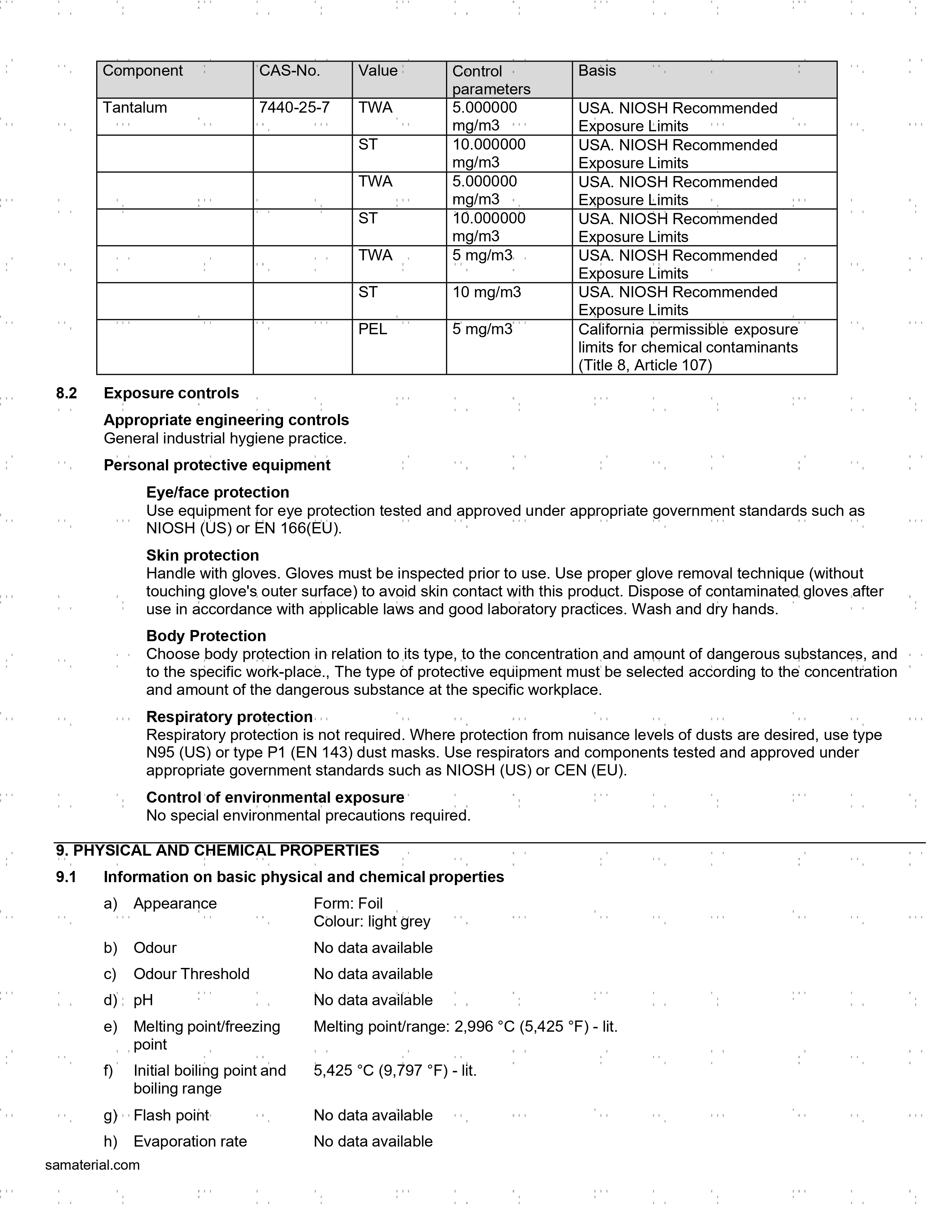

Tantalum Straight Wall Crucibles Specifications

| Diameter (mm) |

Wall Thickness (mm) |

Length (mm) |

| 30 ~ 50 | 2 ~ 10 | 30 ~ 500 |

| 50 ~ 100 | 3 ~ 15 | |

| 100 ~ 150 | 3 ~ 15 | |

| 150 ~ 200 | 5 ~ 20 | |

| 200 ~ 300 | 8 ~ 20 | |

| 300 ~ 400 | 8 ~ 30 | |

| 400 ~ 450 | 8 ~ 30 | |

| 450 ~ 500 | 8 ~ 30 |

The following crucibles are standard crucibles available at Stanford Advanced Materials. Other custom sizes can also be supplied on request.

The crucible product code is composed as follows:

Abbreviations and code:

C conical shaped crucibles

D double wall crucibles

Ø lip

|

|

|

Code: Ta 5-30 |

Code: Ta 10-18 |

|

|

|

Code: Ta 10-32 |

|

Tantalum Crucible Applications

1. High-temperature melting: In high-temperature furnaces, Tantalum Crucibles are used to contain metal or alloy materials for processes such as melting, remelting or purification. Due to their high melting point and excellent corrosion resistance, Tantalum Crucibles ensure material purity and safety.

2. Sintering and heat treatment: Tantalum Crucibles are used to heat and maintain the required temperature of the material during sintering and heat treatment processes. Due to their high hardness and low coefficient of thermal expansion, Tantalum Crucibles can withstand high temperatures and rapid temperature rises, ensuring homogeneous heating of the material and sintering quality.

3. Chemical Reaction Vessels: In chemical reactions, Tantalum Crucibles can be used as corrosion-resistant and high-temperature-resistant containers for a variety of acids, alkalis, salts and other chemical reagents and reaction materials. Due to its excellent corrosion resistance, Tantalum Crucible can ensure the smooth progress of chemical reactions.

4. Application in special fields: In addition to the above applications, Tantalum Crucible also has some applications in special fields, such as high-temperature nuclear fuel treatment in the nuclear industry, high-temperature alloy melting in the aerospace field, etc. In these fields, tantalum crucibles are used to contain various chemical reagents and reaction materials, such as acids and alkalis. In these areas, the high-temperature stability and corrosion resistance of Tantalum Crucibles make them the ideal choice.

Tantalum Crucible Packaging

Our tantalum crucibles are carefully handled to prevent damage during storage and transportation.

Material Safety Data Sheet (MSDS) for your reference!

Tantalum Crucible (Ta Crucible) FAQs

1 Why is Tantalum used to make Crucibles?

Tantalum is known for its exceptional resistance to corrosion, particularly in strong acids, alkalis, and high-temperature environments. It also has a high melting point of 3,020°C, making it an ideal material for crucibles that need to withstand extreme heat and chemical exposure without deteriorating.

2. How does a Tantalum Crucible perform in high temperatures?

Tantalum Crucibles can withstand extremely high temperatures, making them ideal for use in high-temperature applications such as metal melting, smelting, and material processing. They maintain their integrity at temperatures far exceeding the capabilities of most other crucible materials.

3. Is a Tantalum Crucible chemically resistant?

Yes, Tantalum Crucibles are highly resistant to chemical corrosion, even in aggressive environments. They can handle corrosive substances such as acids (including sulfuric and hydrochloric acids) and alkalis, making them suitable for chemical processing, laboratory experiments, and high-precision manufacturing.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!