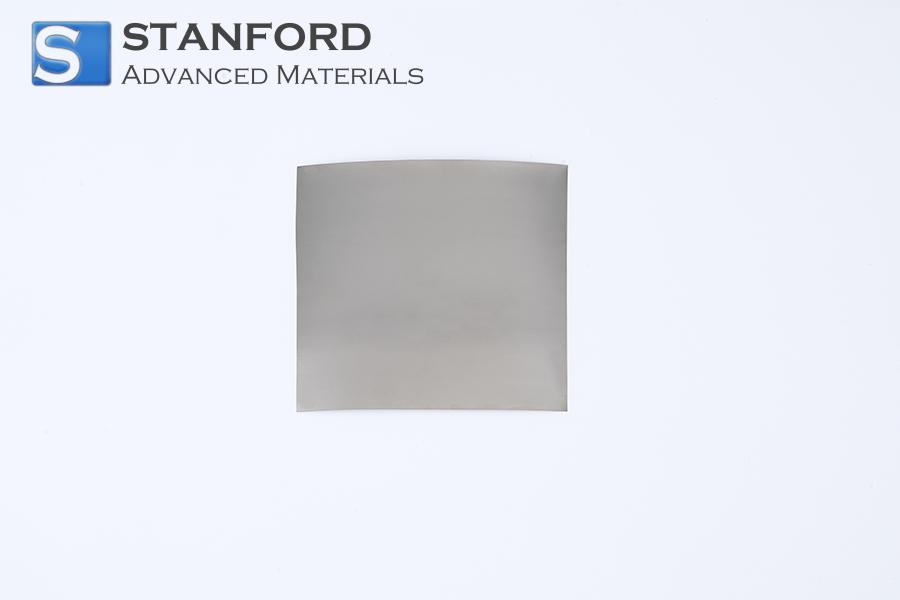

TA0007 Tantalum Disc (Ta Disc)

| Catalog No. | TA0007 |

| Standard | ASTM B708-2001 |

| Size | Diameter: 1" -10"; Thickness: 0.04" - 10" |

| Material | R05200; R05400 |

| Purity | ≥99.95% or 99.99% |

| MSDS/SDS |

At Stanford Advanced Materials (SAM), we offer a wide range of competitively priced, high-quality Tantalum Discs in various sizes. Our commitment to delivering exceptional performance is reflected in our precision-engineered discs. Explore our offerings for a reliable combination of quality and affordability.

Related products: Tantalum Tungsten Disc, Ta Foil/Ta Strip, Ta Sheet/Ta Plate, Ta Tube/Ta Pipe, Ta Capillary, Ta Wire, and Ta Bar/Ta Rod.

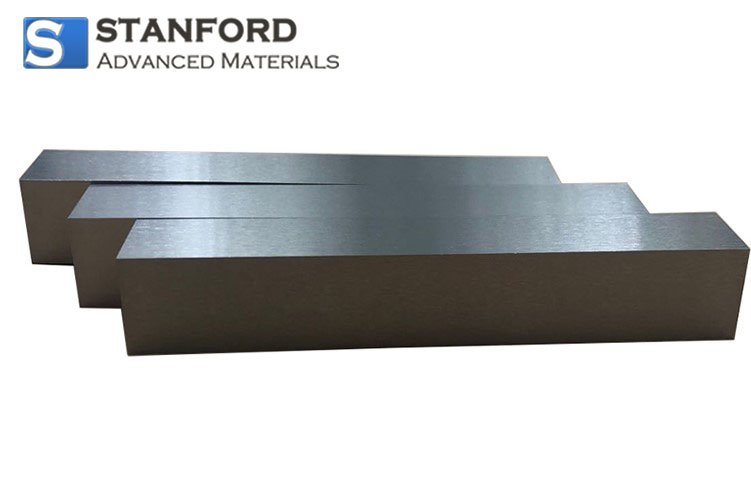

Tantalum Disc Description

Tantalum (Ta) is a dark blue-gray metal that is very heavy, ductile, and hard and has high corrosion resistance. Tantalum is especially resistant to chemicals at temperatures below 150 °C and can only be dissolved with hydrofluoric acid. It has the fourth-highest melting point of all metals and is able to form extremely thin and protective oxide layers for high-quality capacitors, making it an excellent material for discs.

Tantalum Disc is made of tantalum metal. As a leading manufacturer and supplier of tantalum metal and other tantalum products across the world, Stanford Advanced Materials (SAM) offers customers high-quality Tantalum Discs at very competitive prices.

Tantalum Disc Specifications

|

Condition |

Annealed |

|

Diameter |

1" -10" |

|

Thickness |

0.04" - 10" |

|

Material |

R05200; R05400 |

|

Standard |

ASTM B708-2001 |

|

Purity |

≥99.95% or 99.99% |

Stanford Advanced Materials supplies various kinds of Tantalum discs. Customization is available at your request.

Chemical Composition

|

Element |

R05200 (%,Max) |

R05400 (%,Max) |

|

C |

0.01 |

0.01 |

|

O |

0.015 |

0.03 |

|

N |

0.01 |

0.01 |

|

H |

0.0015 |

0.0015 |

|

Fe |

0.01 |

0.01 |

|

Mo |

0.02 |

0.02 |

|

Nb |

0.1 |

0.1 |

|

Ni |

0.01 |

0.01 |

|

Si |

0.005 |

0.005 |

|

Ti |

0.01 |

0.01 |

|

W |

0.05 |

0.05 |

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

In addition to high-quality tantalum discs, SAM also provides Tantalum Sputtering Target whose purity can be up to 99.95%,99.99%, and 99.999%.

Tantalum Disc Applications

Tantalum, a versatile material, finds extensive applications across diverse industries, showcasing its indispensability. In laboratory settings, it plays a crucial role, contributing to the precision and reliability of scientific experiments and analyses. Furthermore, tantalum serves as a notable substitute for platinum, offering a cost-effective yet high-performance alternative in various applications. Its utilization extends to the realm of manufacturing superalloys and electron-beam melting, contributing to the production of advanced materials and technologies. Tantalum's significance is further underscored in metallurgical, machinery processing, glass, and ceramic industries, where its unique properties enhance the efficiency and quality of various processes.

Tantalum Disc Packaging

Our tantalum disc is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Material Safety Data Sheet (MSDS) for your reference!

Tantalum Disc FAQs

1 Why is Tantalum Disc used instead of other materials?

Tantalum Disc offers exceptional resistance to corrosion, even in aggressive environments like sulfuric acid or chlorine. Its high melting point of 3,020°C makes it ideal for high-temperature applications. Furthermore, it is biocompatible, making it suitable for medical implants such as pacemakers or surgical tools.

2. How is Tantalum Disc manufactured?

Tantalum Discs are produced by cutting or stamping high-purity tantalum metal into circular shapes. They can also be manufactured through casting or other precision manufacturing methods to meet specific size and thickness requirements.

3 Can Tantalum Discs be customized?

Yes, Tantalum Discs can be customized in terms of size, thickness, and purity to meet specific industrial or scientific requirements. Custom discs can be produced for a wide range of applications, from medical implants to aerospace components.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!