TA0001 Tantalum Ingot (Ta Ingot)

| Catalog No. | TA0001 |

| Size | Diameter 70-195 mm Length <=1600 mm |

| Material | R05200 R05400 |

| CAS Number | 7440-25-7 |

| Standard | ASTM B364-92 |

| Purity | >=99.9% or 99.95% |

| MSDS/SDS |

High-quality Tantalum Ingot (Ta Ingot) is on sale at Stanford Advanced Materials (SAM). As a leading global tantalum products supplier, SAM provides customers with high-quality tantalum ingots at a very competitive price. We can also offer custom tantalum products per your specs.

Related products: Tantalum Foil, Tantalum Sheet, Tantalum Tube, Tantalum Capillary, Tantalum Wire, Tantalum Bar.

Tantalum Ingot Description

Tantalum Ingot (Ta Ingot) of high quality is available at Stanford Advanced Materials (SAM). Tantalum Ingot is made of Tantalum (Ta), which is a dark blue-gray metal that is very heavy, ductile, and hard and has high corrosion resistance. Tantalum is especially resistant to chemicals at temperatures below 150 °C and can only be dissolved with hydrofluoric acid. It has a high melting point and is able to form extremely thin and protective oxide layers.

As a leading tantalum products supplier across the world, Stanford Advanced Materials offers customers high-quality Tantalum Ingots at a very competitive price.

Tantalum Ingot Specifications

|

Size |

Diameter (mm) 70-195; |

|

Length (mm) |

<=1600 |

|

Material |

R05200, R05400 |

|

Standard |

ASTM B364-92 |

|

Purity |

>=99.9% or 99.95% |

We can tailor-made tantalum ingot to fit your specific requirements.

Chemical Composition

|

Element |

R05200 (%,Max) |

R05400 (%,Max) |

|

C |

0.01 |

0.01 |

|

O |

0.015 |

0.03 |

|

N |

0.01 |

0.01 |

|

H |

0.0015 |

0.0015 |

|

Fe |

0.01 |

0.01 |

|

Mo |

0.02 |

0.02 |

|

Nb |

0.1 |

0.1 |

|

Ni |

0.01 |

0.01 |

|

Si |

0.005 |

0.005 |

|

Ti |

0.01 |

0.01 |

|

W |

0.05 |

0.05 |

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum tungsten alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum niobium alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Ingot Applications

1. Laboratory Equipment: Tantalum heating elements are extensively utilized in laboratory settings, providing precise and controlled heating for a wide range of experiments, tests, and research applications.

2. Substitute for Platinum: Tantalum serves as an effective substitute for platinum in various applications due to its high melting point, corrosion resistance, and cost-effectiveness, making it a preferred choice in certain industrial processes.

3. Superalloys and Electron-Beam Melting: Tantalum is integral in producing superalloys, enhancing their strength and corrosion resistance. It is also employed in electron-beam melting processes, contributing to the creation of high-performance materials.

4. Metallurgical, Machinery, Glass, and Ceramic Industries: Tantalum finds application in diverse industries, including metallurgy, machinery processing, glass, and ceramics, where its unique properties contribute to the manufacturing of durable and reliable components.

5. Superalloy Additive: Tantalum acts as a crucial additive in nickel-based superalloys, improving their overall performance in high-stress and high-temperature environments, making them suitable for applications in aerospace and other demanding industries.

6. Sputtering Targets: Tantalum is employed in the production of sputtering targets, playing a key role in thin-film deposition processes used in the semiconductor industry and other applications requiring precise material deposition.

Tantalum Ingot Packaging

Our tantalum ingots are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

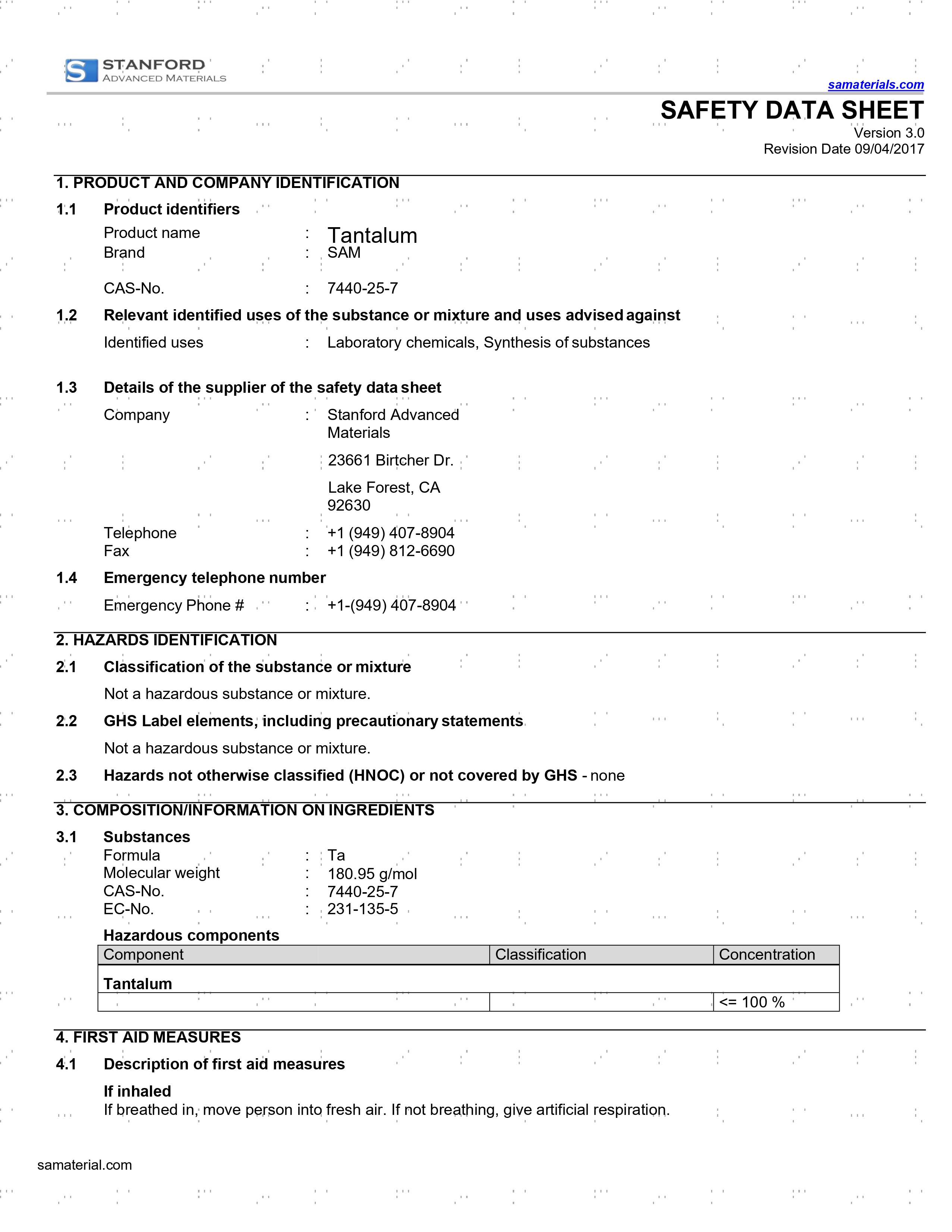

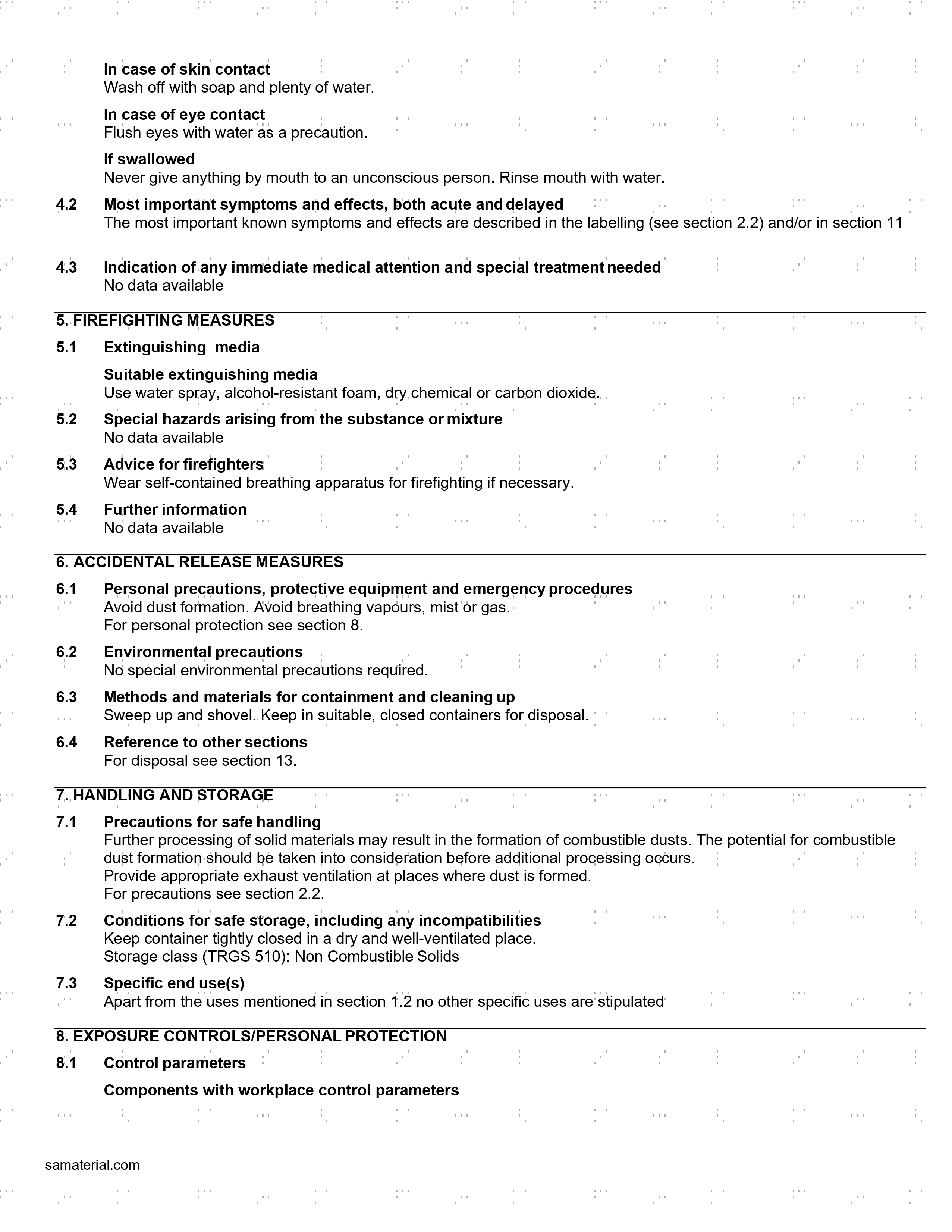

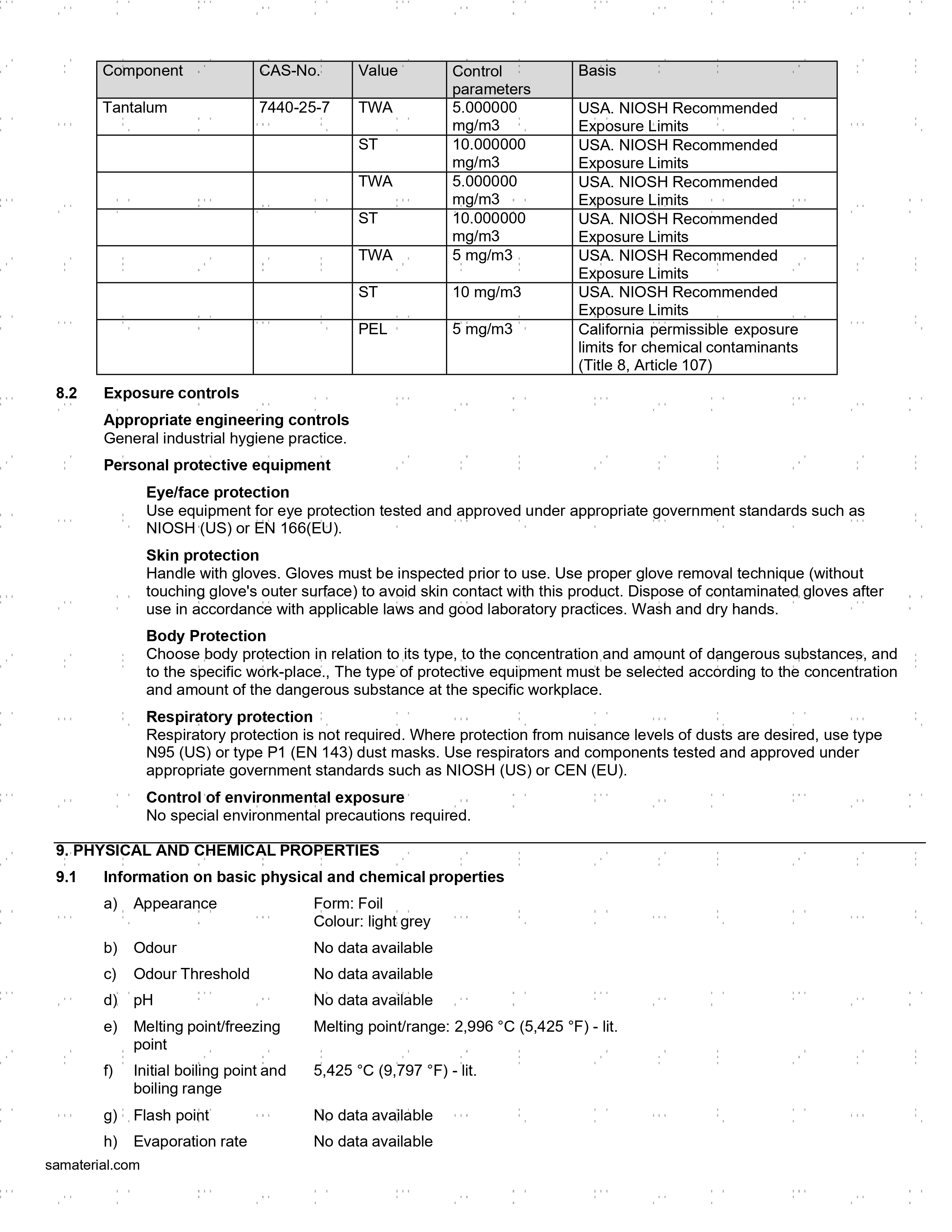

Material Safety Data Sheet (MSDS) for your reference!

Tantalum Ingot (Ta Ingot) FAQs

1.How is Tantalum Ingot produced?

Tantalum Ingots are produced through a refining process that includes ore extraction, reduction, and vacuum melting to achieve high purity and optimal material properties.

2. Why is Tantalum preferred for electronic components?

Tantalum has excellent electrical conductivity and stability, making it ideal for manufacturing capacitors and high-performance electronic components.

3. Is Tantalum Ingot corrosion-resistant?

Yes, tantalum is highly resistant to corrosion, even in strong acids such as hydrochloric acid and sulfuric acid, making it suitable for chemical processing equipment.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!