- Products

- Categories

- Blog

- Podcast

- Application

- Document

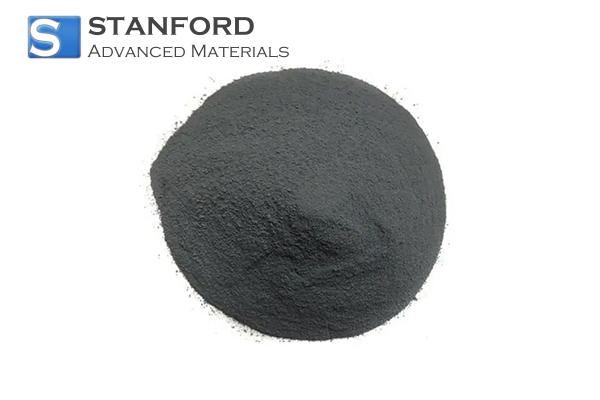

SN3982 SnAg3.0Cu0.5 Tin-based Alloy Solder Powder

| Catalog No. | SN3982 |

| Compositions | Sn/Ag/Cu |

| Appearance | Grey powder |

SnAg3.0Cu0.5 Tin-based Alloy Solder Powder has better wetting and spread ability. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality SnAg3.0Cu0.5 Tin-based Alloy Solder Powder.

Related products: SnCu0.7 Tin-based Alloy Solder Powder, SnAg0.3Cu0.7 Tin-based Alloy Solder Powder, SnAg1.0Cu0.5 Tin-based Alloy Solder Powder, SnSb5 Tin-based Alloy Solder Powder

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!