Antimony Doped Tin Oxide (ATO) Evaporation Materials Description

Antimony Doped Tin Oxide (ATO) Evaporation Materials are at the forefront of innovations in transparent conductive coatings. By combining tin oxide with antimony, these materials offer unique electrical and optical properties, making them an ideal choice for various applications in thin-film deposition.

Key Features:

-

Transparent Conductivity: ATO combines high transparency with excellent electrical conductivity, making it a preferred material for transparent conductive coatings in applications like solar cells and displays.

-

Uniform Deposition: Our ATO Evaporation Materials are designed for consistent and uniform deposition, ensuring the quality and performance of the coated films.

-

Optical Enhancement: The addition of antimony enhances the optical properties of tin oxide, contributing to improved light transmission and reduced reflectance.

-

Customizable: Tailor the properties of your thin films by choosing ATO Evaporation Materials with specific antimony doping levels, allowing for customization based on your application requirements.

Antimony Doped Tin Oxide (ATO) Evaporation Materials Specifications

| Property |

Value |

| Chemical Composition |

SnO2:Sb |

| Doping Level |

Customizable |

| Purity |

99.99% |

| Melting Point |

1,720°C |

| Density |

6.9 g/cm³ |

| Optical Transmission |

> 80% at 550 nm |

| Electrical Conductivity |

~ 10-20 Ω/square |

| Crystal Structure |

Tetragonal |

Antimony Doped Tin Oxide (ATO) Evaporation Materials Applications

-

Solar Cells: ATO coatings contribute to the efficiency of solar cells by providing a transparent conductive layer.

-

Displays: Transparent conductive coatings are essential in the manufacturing of touchscreens, LCDs, and other display technologies.

-

Smart Windows: ATO-coated windows enable the control of light transmission, finding applications in energy-efficient smart windows.

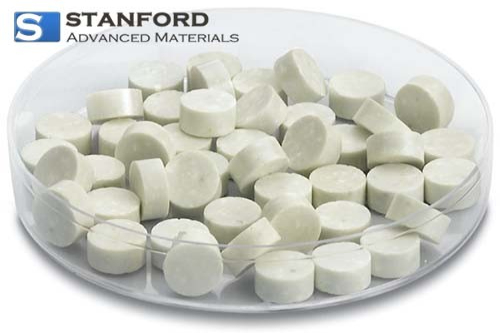

Antimony Doped Tin Oxide (ATO) Evaporation Materials Packing

Our ATO Evaporation Materials are meticulously packed to ensure their integrity during transportation and storage. The standard packing includes vacuum-sealed plastic bags within a protective outer case.

Why Choose Our Antimony Doped Tin Oxide (ATO) Evaporation Materials?

-

Quality Assurance: Rigorous quality control processes ensure that our products meet the highest industry standards.

-

Customization: We offer customizable doping levels to meet the specific requirements of your applications.

-

Expert Support: Our team of experts is ready to assist you, providing technical guidance and support.

For inquiries, customization, or to place an order, please contact us. Explore the possibilities with Antimony Doped Tin Oxide (ATO) Evaporation Materials.