Description

Tin (Sn) Evaporation Materials possess a distinct set of properties that render them highly suitable for a wide range of applications. These materials exhibit excellent thermal stability, enabling them to maintain their structural integrity even under high-temperature conditions. This characteristic is crucial for evaporation processes, where materials are often exposed to significant heat.

Furthermore, Tin Evaporation Materials demonstrate high evaporation rates, which is essential for efficient and controlled deposition of thin films. This allows for precise and uniform coating on various substrates, crucial for achieving desired optical, electrical, or mechanical properties.

Additionally, Tin Evaporation Materials possess good electrical conductivity, making them suitable for applications where electrical performance is a key requirement. Their ability to form smooth and adherent films also contributes to their effectiveness in electronic devices.

Moreover, Tin Evaporation Materials are known for their excellent corrosion resistance. This property enables them to withstand harsh environmental conditions, ensuring the durability and longevity of coatings.

Specification

|

Material

|

Tin

|

|

Atomic Weight

|

118.71

|

|

Color/Appearance

|

Silvery Lustrous Gray, Metallic

|

|

Thermal Conductivity

|

66.6 W/m.K

|

|

Melting Point (°C)

|

232

|

|

Coefficient of Thermal Expansion

|

22 x 10-6/K

|

|

Theoretical Density (g/cc)

|

7.28

|

|

Z Ratio

|

0.724

|

|

Temp. (°C) for Given Vap. Press. (Torr)

|

10^-8: 682 10^-6: 807 10^-4: 997

|

Applications

1. Thin-Film Coatings: Tin Evaporation Materials are commonly used in the deposition of thin films on various substrates. These films can enhance the surface properties of materials, such as reflectivity, conductivity, and corrosion resistance. They find applications in electronics, photovoltaics, and optical coatings, among others.

2. Electronics: Tin Evaporation Materials are essential in the production of electronic components and devices. Their excellent electrical conductivity and ability to form smooth films make them suitable for use in integrated circuits, semiconductors, and thin-film transistors.

3. Solar Cells: Tin-based evaporation materials play a crucial role in the manufacturing of solar cells. Thin films of Tin can be deposited on photovoltaic materials to enhance their light absorption and conversion efficiency, thus improving the performance of solar cells.

4. Optical Coatings: Tin Evaporation Materials are also used in the production of optical coatings. These coatings can improve the optical properties of glass or plastic substrates, such as transmittance, reflectivity, and anti-reflection. They are widely used in eyewear, camera lenses, and other optical devices.

5. Packaging and Corrosion Protection: Tin Evaporation Materials can be used to create protective coatings on metals, alloys, and other materials to enhance their corrosion resistance. This is particularly important in the packaging industry, where Tin coatings can provide a durable barrier against moisture and oxidation, protecting the integrity of packaged goods.

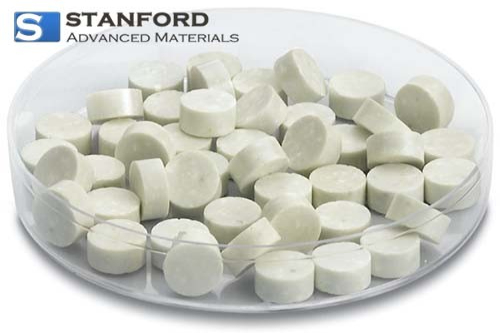

Packaging:

Our evaporation materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.