- Products

- Categories

- Blog

- Podcast

- Application

- Document

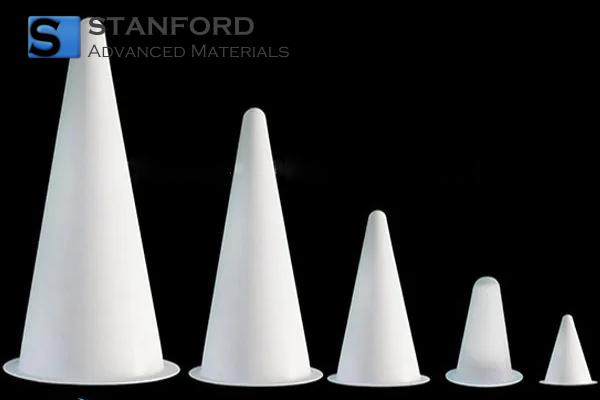

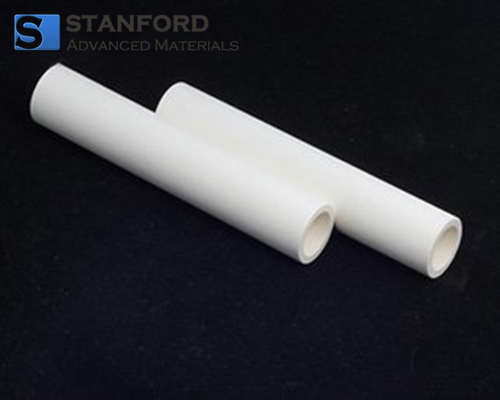

PBN4686 Pyrolytic Boron Nitride Crucible (MBE Type)

| Catalog No. | PBN4686 |

| Material | PBN |

| Purity | >99.99% |

| Density | 1.95-2.20 g/cm3 |

| Size | Customized |

Pyrolytic Boron Nitride Crucible (MBE Type) is a specialized container designed for use in Molecular Beam Epitaxy (MBE) systems. Stanford Advanced Materials (SAM) offers Pyrolytic Boron Nitride Crucible renowned for exceptional quality, all at highly competitive prices.

Related products: PBN Crucibles, PBN LEC Crucible, PBN VGF Crucible, PBN OLED Crucible

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!