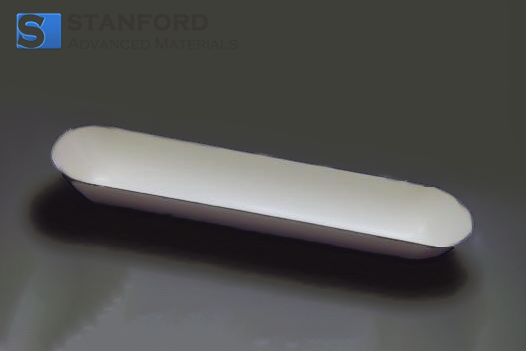

Pyrolytic Boron Nitride (PBN) Boat Description

Pyrolytic Boron Nitride (PBN) Boats are highly specialized containers known for their exceptional thermal and chemical properties. PBN is synthesized through chemical vapor deposition, resulting in a material with excellent thermal conductivity and high-temperature stability, capable of withstanding temperatures up to 2000°C in inert atmospheres. PBN is chemically inert, resistant to most acids and alkalis, and does not react with molten metals, making it ideal for use in high-purity environments. Additionally, it exhibits outstanding electrical insulation properties and low outgassing, ensuring minimal contamination in sensitive processes. These characteristics make PBN boats particularly suitable for use in crystal growth, semiconductor manufacturing, and high-temperature material processing applications.

Pyrolytic Boron Nitride (PBN) Boat Specification

Normal Size:

|

Length

|

Height

|

Thickness

|

|

2”-20”

|

0.5”-2”

|

0.035”-0.08”

|

For specific sizes, please contact us.

Physical Parameters of Pyrolytic Boron Nitride (PBN) Boat

|

Material

|

PBN

|

|

Bulk Density

|

2.0-2.19g/cm3

|

|

Wall thickness

|

<2mm

|

|

Max. Working Temperature

|

2400℃

|

|

Volume Resistivity (Ω·cm)

|

3.11*1011

|

|

Thermal Conductivity (W/M·k)

|

43-60

|

|

Tensile Strength (N/mm2)

|

153.86 (parallel)

|

|

Bending Strength (N/mm2)

|

243.63 (parallel)

|

|

Dielectric Strength (RT) (KV/mm)

|

56

|

Pyrolytic Boron Nitride (PBN) Boat Applications

1. Semiconductor Industry: Used in the fabrication and processing of semiconductor wafers, particularly in high-temperature and high-purity environments.

2. Crystal Growth: Ideal for the growth of high-purity crystals, such as gallium arsenide (GaAs) and other compound semiconductors, due to their non-reactive nature and thermal stability.

3. Material Processing: Employed in the evaporation and deposition of metals and compounds, ensuring minimal contamination and high purity of the processed materials.

4. High-Temperature Furnaces: Used as containers and supports in high-temperature furnaces and reactors, benefiting from their thermal stability and resistance to chemical attack.

5. Chemical Processing: Suitable for handling corrosive chemicals and molten metals, providing durability and longevity in harsh chemical environments.

6. Research and Development: Utilized in various R&D applications where high-purity and high-temperature conditions are essential, including the development of new materials and processes.

7. Aerospace: Used in the production of high-temperature components and coatings for aerospace applications, leveraging their thermal and chemical stability.

Pyrolytic Boron Nitride (PBN) Boat Packaging

Our Pyrolytic Boron Nitride (PBN) Boat is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Pyrolytic Boron Nitride (PBN) Boat FAQs

Q1: What is a Pyrolytic Boron Nitride (PBN) Boat?

A Pyrolytic Boron Nitride (PBN) Boat is a high-performance ceramic vessel or container made from pyrolytic boron nitride, often used in high-temperature applications. These boats are primarily used to hold materials during processes like chemical vapor deposition (CVD), sintering, and other high-temperature reactions, as they offer superior thermal and chemical stability.

Q2: What is the advantage of using Pyrolytic Boron Nitride (PBN) Boat?

Superior Thermal and Chemical Stability: Unlike traditional materials like quartz or graphite, Pyrolytic Boron Nitride (PBN) Boat can withstand higher temperatures and is more chemically stable, especially in reactive atmospheres.

Non-contaminating: Pyrolytic Boron Nitride (PBN) Boat is non-reactive and does not contaminate the material being processed, which is essential in semiconductor and advanced materials industries where purity is critical.

Low Thermal Expansion: Pyrolytic Boron Nitride (PBN) Boat has low thermal expansion, which ensures dimensional stability during temperature fluctuations, reducing the risk of warping or cracking.

Q3: What are the size and shape options for PBN Boats?

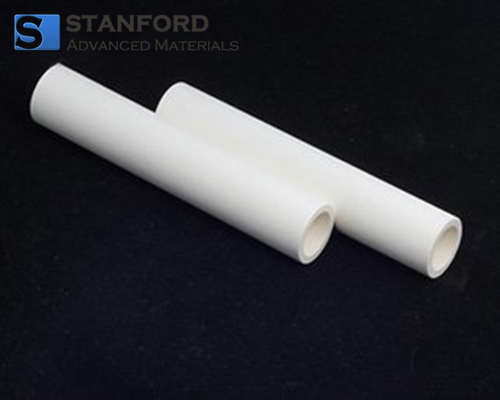

PBN boats come in various sizes and shapes, and many suppliers offer custom solutions tailored to specific applications. Common shapes include:

Flat-bottomed boats: Ideal for processes like sintering or wafer handling.

Vessels and crucibles: Used for chemical reactions or material synthesis.

Custom-designed shapes: Tailored to meet specific process or material handling requirements.

The size of the boat depends on the intended use, and manufacturers often offer options from small laboratory-scale boats to large-scale industrial versions.

Related articles:

Pyrolytic Boron Nitride: layered structure and simple quality assurance

Boron Nitride ceramic: A bullet proof material

How Stanford Advanced Materials Provided Customized Boron Nitride Refractory Devices

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano