Vanadium Aluminum (V/Al) Evaporation Materials Description

Embark on a journey into the realm of advanced thin-film technology with Vanadium Aluminum (V/Al) Evaporation Materials. This unique alloy seamlessly combines the distinctive properties of vanadium and aluminum, unlocking a new paradigm in thin-film deposition. Crafted for precision and versatility, these evaporation materials redefine possibilities in thin-film applications.

Key Features

-

Synergistic Alloy - V/Al materials harness the complementary properties of vanadium and aluminum, creating a synergistic alloy for enhanced thin-film performance.

-

Elevated Melting Points - Enjoy the benefits of heightened melting points contributed by both vanadium (1910°C) and aluminum (660.3°C), ensuring stability and durability in the thin-film deposition process.

-

Thermal Stability - The alloy's composition imparts exceptional thermal stability, a critical attribute for applications exposed to high temperatures.

-

Versatile Applications - V/Al materials find applications across diverse industries, from electronics to optics, owing to their adaptable properties.

Vanadium Aluminum Evaporation Materials Specifications

| Property |

Value |

| Composition |

Vanadium/Aluminum (V/Al) |

| Purity |

99.9% |

| Melting Point |

Vanadium: 1910°C, Aluminum: 660.3°C |

| Density |

Vanadium: 6.11 g/cm³, Aluminum: 2.70 g/cm³ |

| Thermal Conductivity |

Vanadium: 30.7 W/m·K, Aluminum: 237 W/m·K |

| Coefficient of Expansion |

Vanadium: 8.4 × 10⁻⁶/K, Aluminum: 23.1 × 10⁻⁶/K |

Vanadium Aluminum Evaporation Materials Applications

-

Electronics - V/Al materials play a pivotal role in the fabrication of advanced electronic devices, contributing to semiconductor manufacturing through thin-film technology.

-

Optical Coatings - The versatility of V/Al materials makes them suitable for optical coatings, ensuring optimal performance in various optical applications.

-

Solar Cells - Applied in the thin-film deposition of materials for solar cells, V/Al materials contribute to the advancement of solar energy technology.

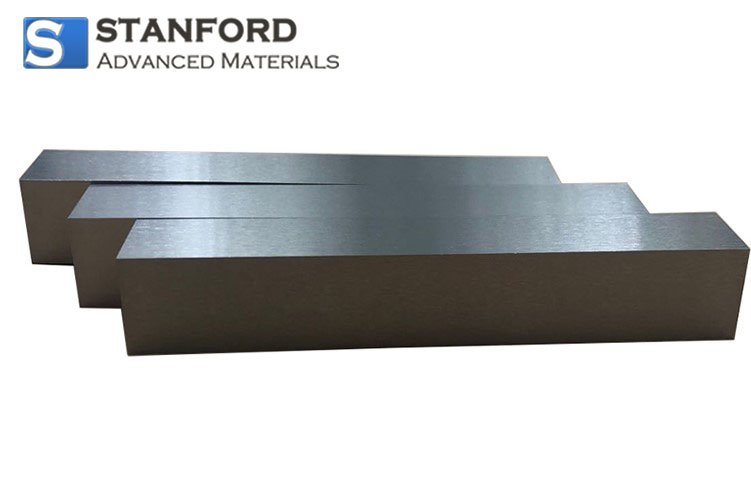

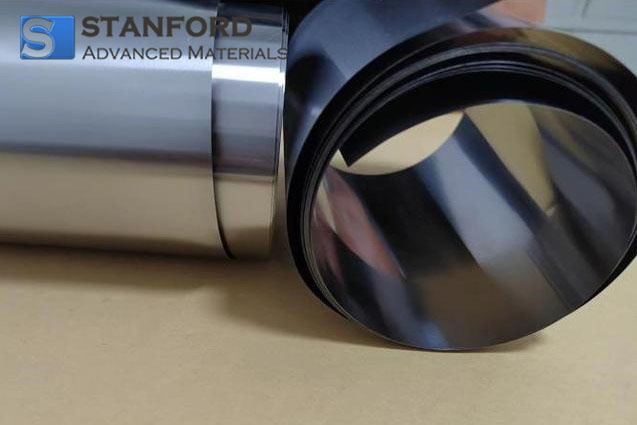

Vanadium Aluminum Evaporation Materials Packing

Our Vanadium Aluminum (V/Al) Evaporation Materials undergo meticulous packaging to ensure their integrity during transportation and storage. The materials are hermetically sealed in vacuum packaging and further enclosed in protective outer packaging.

Why Choose Our Vanadium Aluminum Evaporation Materials?

-

High Purity - Exhibiting exceptional purity, our V/Al materials meet the stringent requirements of thin-film deposition processes.

-

Customization - Tailor the composition and form of V/Al materials to meet the specific needs of your thin-film deposition projects, ensuring flexibility for diverse applications.

-

Technical Excellence - Backed by technical expertise, our V/Al evaporation materials deliver reliable performance, contributing to the success of your thin-film endeavors.

Embark on the future of thin-film technology with Vanadium Aluminum (V/Al) Evaporation Materials. For inquiries, customizations, or to place an order, please contact us.