Precious Metal Crucible: Types and Applications

Introduction

Precious metal crucibles are essential tools in various high-temperature applications due to their superior resistance to heat and chemical corrosion. Here’s an overview of the types and applications of precious metal crucibles:

Types of Precious Metal Crucibles

1. Platinum Crucibles

Platinum crucibles are known for their high melting point of 1,768°C, making them suitable for high-temperature applications. They exhibit excellent resistance to oxidation and corrosion and are non-reactive with most materials.

These properties make platinum crucibles indispensable in chemical analysis, glass manufacturing, the semiconductor industry, and high-purity metal synthesis.

Related reading: Precious vs. Refractory: An Exploration of Metal Crucibles

2. Gold Crucibles

Gold crucibles, with a melting point of 1,064°C, offer excellent corrosion resistance and good thermal conductivity.

They are non-reactive with most chemicals, which makes them ideal for the preparation of fluorides and for fusions requiring low to moderate temperatures.

3. Silver Crucibles

Silver crucibles, which melt at 961.8°C, are prized for their good thermal conductivity and excellent chemical resistance, particularly to fluorine and its compounds.

They are employed in the preparation of samples for analysis involving fluorine compounds and in specific chemical reactions where their moderate melting point is advantageous.

4. Palladium Crucibles

Palladium crucibles have a high melting point of 1,554.9°C and offer excellent resistance to oxidation and corrosion.

They are relatively inert chemically, making them suitable for specialized chemical processes, catalytic research, and some high-temperature fusions.

5. Rhodium Crucibles

Rhodium crucibles boast a very high melting point of 1,964°C and provide excellent resistance to oxidation and corrosion.

They are very stable at high temperatures and are often used in conjunction with platinum in high-temperature applications, particularly in the glass industry and for certain chemical syntheses.

6. Iridium Crucibles

Iridium crucibles, with an extremely high melting point of 2,446°C, are known for their superior resistance to corrosion and oxidation.

They are very hard and brittle, making them suitable for extremely high-temperature applications and specialized high-purity chemical processes.

Applications of Precious Metal Crucibles

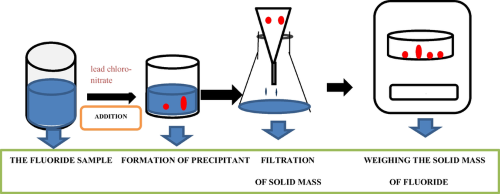

--Analytical Chemistry

Precious metal crucibles are essential tools in laboratories for precise and accurate chemical analysis, particularly in processes requiring high temperatures and resistance to contamination. Here are some common uses of precious metal crucibles in analytical chemistry:

- Precious metal crucibles are used to determine the amount of a substance by measuring its mass. They withstand high temperatures required to drive off volatile substances, leaving behind the analyte for precise weighing.

[1]

[1]

2. Fusion Processes

- In sample preparation, fusion with fluxes (e.g., lithium borate) requires crucibles that can handle high temperatures and corrosive conditions. Platinum crucibles are often used for fusing geological and mineral samples.

3. Ashing

- Ashing involves the decomposition of organic materials at high temperatures to analyze the remaining inorganic content. Precious metal crucibles ensure no reaction with the ash, preserving the integrity of the residue.

4. Chemical Digestion

- For breaking down complex matrices into simpler components, chemical digestion is performed in precious metal crucibles that resist attack from strong acids and oxidizing agents, facilitating subsequent analysis.

5. Thermal Analysis

- Techniques like thermogravimetric analysis (TGA) and differential thermal analysis (DTA) require crucibles that can handle rapid heating and cooling cycles without compromising the sample or the analysis.

6. Catalyst Preparation and Testing

- Precious metal crucibles are used to prepare and test catalysts, especially when studying reactions at high temperatures. Their inertness ensures that the crucible does not affect the catalytic properties being measured.

--Glass Manufacturing

In glass manufacturing, precious metal crucibles are useful for producing high-purity glass and optical fibers, where resistance to high temperatures and chemical corrosion is crucial. Their unique properties ensure the integrity and quality of the glass throughout various stages of production.

1. Melting and Refining

- Precious metal crucibles are used to melt raw materials and refine the glass by removing impurities. Their high melting points and inertness ensure that the crucible material does not mix with the glass, maintaining the integrity of the melt.

2. Specialty Glass Production

- For producing specialty glasses, such as borosilicate, lead glass, and high-purity silica glass, crucibles made of platinum or platinum alloys are essential. These glasses require precise control over the melting process to achieve specific optical and physical properties.

3. Optical Fiber Manufacturing

- In the production of optical fibers, maintaining the purity of the glass is crucial. Platinum crucibles are used to melt the preform materials because they do not introduce impurities and can withstand the high temperatures needed for fiber drawing.

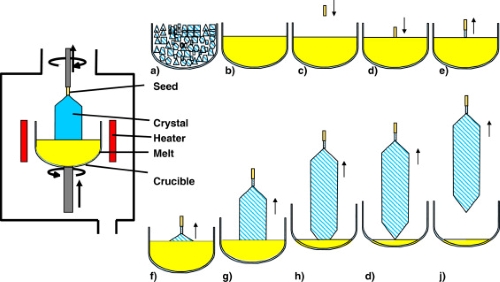

--Semiconductor Industry

These crucibles also find uses in the semiconductor industry, particularly in processes that require high-purity environments and the growth of single crystals. They are essential for maintaining the integrity and purity of semiconductor materials.

1. Crystal Growth

- Crucibles made of platinum and platinum alloys are essential in the Czochralski process, used to grow single crystal silicon, germanium, and other semiconductor crystals. The high melting point and chemical inertness of platinum prevent contamination during crystal growth, ensuring high-purity crystals.

[2]

[2]

2. Doping Processes

- In semiconductor doping, where impurities are intentionally introduced to modify electrical properties, precious metal crucibles are used to melt and mix the materials without introducing additional contaminants.

3. Epitaxial Growth

- During epitaxial layer growth, where layers of semiconductor materials are deposited on a substrate, precious metal crucibles ensure the purity of the source materials and maintain the quality of the epitaxial layers.

4. Oxidation and Annealing

- High-temperature processes like oxidation and annealing, used to modify the properties of semiconductor wafers, benefit from the use of platinum crucibles due to their ability to withstand high temperatures and corrosive environments.

--Other Common Uses

Beyond the semiconductor industry, precious metal crucibles find critical applications in several other high-temperature and high-purity processes.

1. High-Purity Metal Synthesis: Precious metal crucibles are essential for the production and refinement of high-purity metals, ensuring no contamination during high-temperature processes.

2. Catalytic Research: These crucibles are used in the study and development of catalysts, particularly in reactions that involve high temperatures and harsh chemical environments.

3. Thermal Analysis: Precious metal crucibles are employed in differential thermal analysis (DTA) and thermogravimetric analysis (TGA), where materials are studied under controlled temperature conditions.

Conclusion

In summary, with high melting points, chemical inertness, and resistance to corrosion, precious metal crucibles are vital in analytical chemistry, glass manufacturing, semiconductor processing, or high-purity metal synthesis. The choice of crucible type depends on the specific requirements of each application, highlighting the versatility and importance of these tools in advanced material processing and research. For more precious metal products and quality crucibles, please check Stanford Advanced Materials (SAM).

Reference:

[1] Khatkar, Rahul & Nagpal, Suman. (2023). Conventional and advanced detection approaches of fluoride in water: a review. Environmental Monitoring and Assessment. 195. 10.1007/s10661-022-10888-x.

[2] J. Friedrich, Methods for Bulk Growth of Inorganic Crystals: Crystal Growth, Reference Module in Materials Science and Materials Engineering, Elsevier, 2016, https://www.sciencedirect.com/science/article/pii/B9780128035818010109