Nano Aluminum Oxide for Coating Description

Nano Aluminum Oxide for Coating features anti-scratch, high wear resistance, and excellent resistance performance. After it is added to the paint, a superfine, uniform, and hard network structure is formed on the surface of the paint to protect the underlying polymer paint layer from damage. The scratch performance is 3 times better than that of the original paint. The coating added by Nano Al2O3 for Coating greatly improves the wear resistance, which is 2 to 4 times higher than that of the traditional ones.

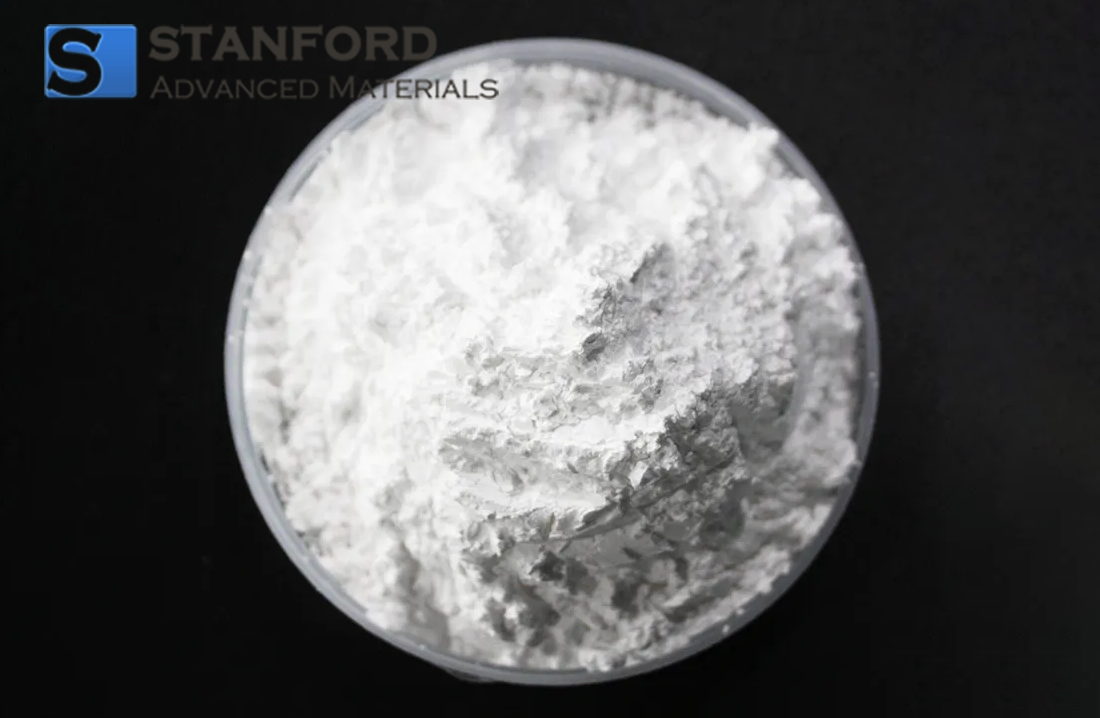

Nano Aluminum Oxide for Coating Specification

|

Grade

|

R30

|

R30A

|

|

Average Particle Size

|

30 nm

|

30 nm

|

|

Specific Surface Area (m2/g)

|

80-120

|

80-120

|

|

Form

|

White powder

|

White powder

|

|

Purity

|

99.99%

|

99.99%

|

|

Surface properties

|

Hydrophilic

|

Lipophilic

|

Nano Aluminum Oxide for Coating Applications

Nano Aluminum Oxide for Coating is mainly used in automotive coatings and furniture coatings.

- Protective Coatings: Utilized as a key component in protective coatings for surfaces exposed to harsh environments, Nano Aluminum Oxide provides enhanced durability, corrosion resistance, and wear protection.

- Abrasion Resistance: Incorporated into coatings for machinery, tools, and equipment surfaces, Nano Aluminum Oxide reinforces abrasion resistance, extending the lifespan and performance of these components.

- Optical Coatings: In optical applications, Nano Aluminum Oxide is used in coatings for lenses, mirrors, and other optical devices, providing improved scratch resistance and optical clarity.

- Anti-Reflective Coatings: Its nanostructure makes it suitable for anti-reflective coatings on glass surfaces, reducing glare and improving optical performance.

- Thermal Barrier Coatings: Nano Aluminum Oxide finds application in thermal barrier coatings, providing insulation and heat resistance to components in high-temperature environments.

Nano Aluminum Oxide for Coating Packaging

Our Nano Aluminum Oxide for Coating is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Nano Aluminum Oxide for Coating FAQs

Q1: What are the key properties of nano aluminum oxide for coatings?

A: Key properties include high hardness, chemical inertness, high thermal stability, excellent wear resistance, and the ability to form smooth, uniform coatings.

Q2: What factors should be considered when selecting nano aluminum oxide for coating applications?

A: Factors to consider include the particle size, purity of the nano aluminum oxide, compatibility with the substrate material, the desired thickness of the coating, and the specific application requirements such as hardness, transparency, or thermal resistance.

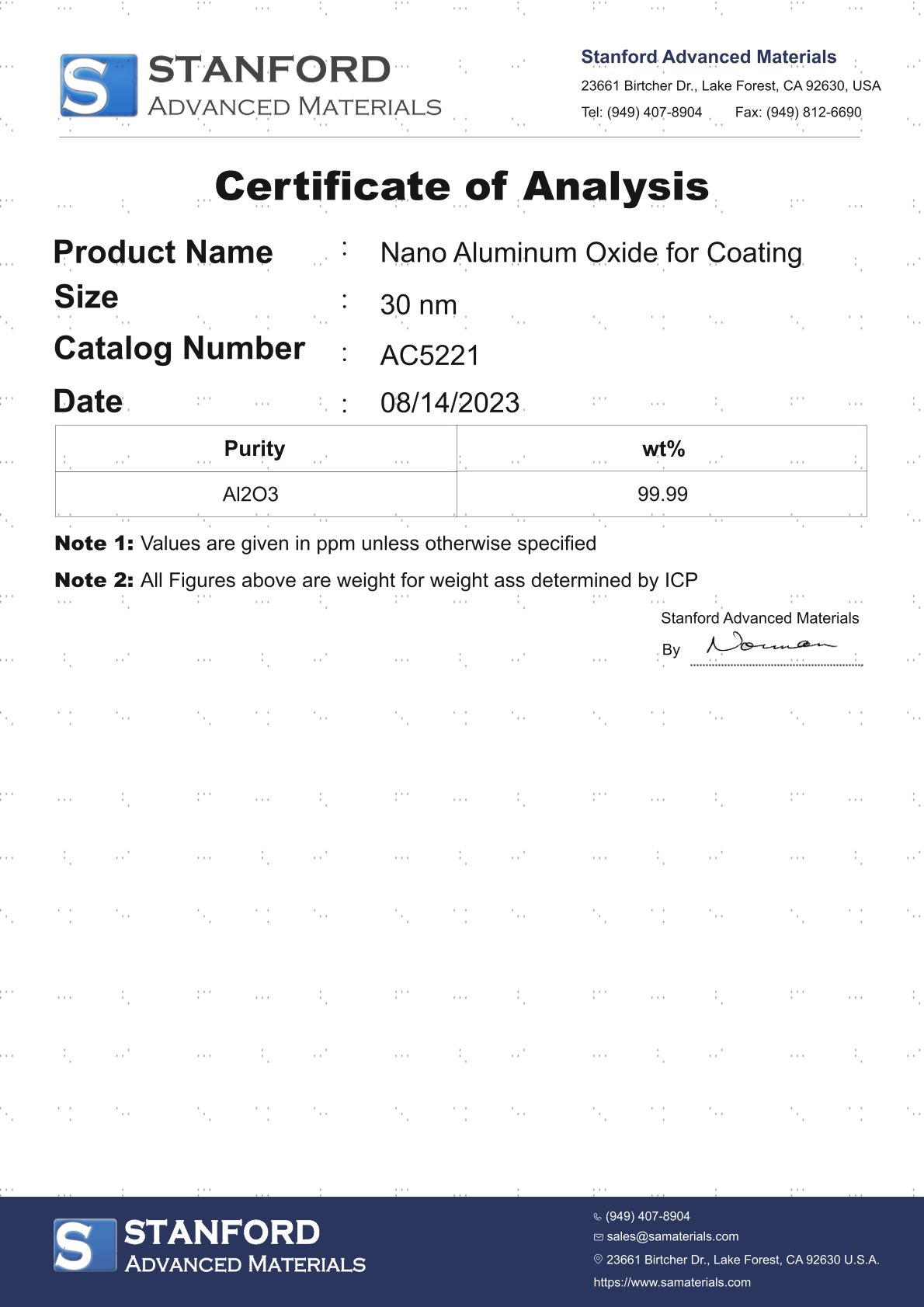

Q3: How is the quality of nano aluminum oxide for coatings verified?

A: Quality is verified using techniques such as particle size analysis (e.g., laser diffraction), chemical composition analysis, scanning electron microscopy (SEM) for morphological examination, and adhesion and durability testing of the coatings.