- Products

- Categories

- Blog

- Podcast

- Application

- Document

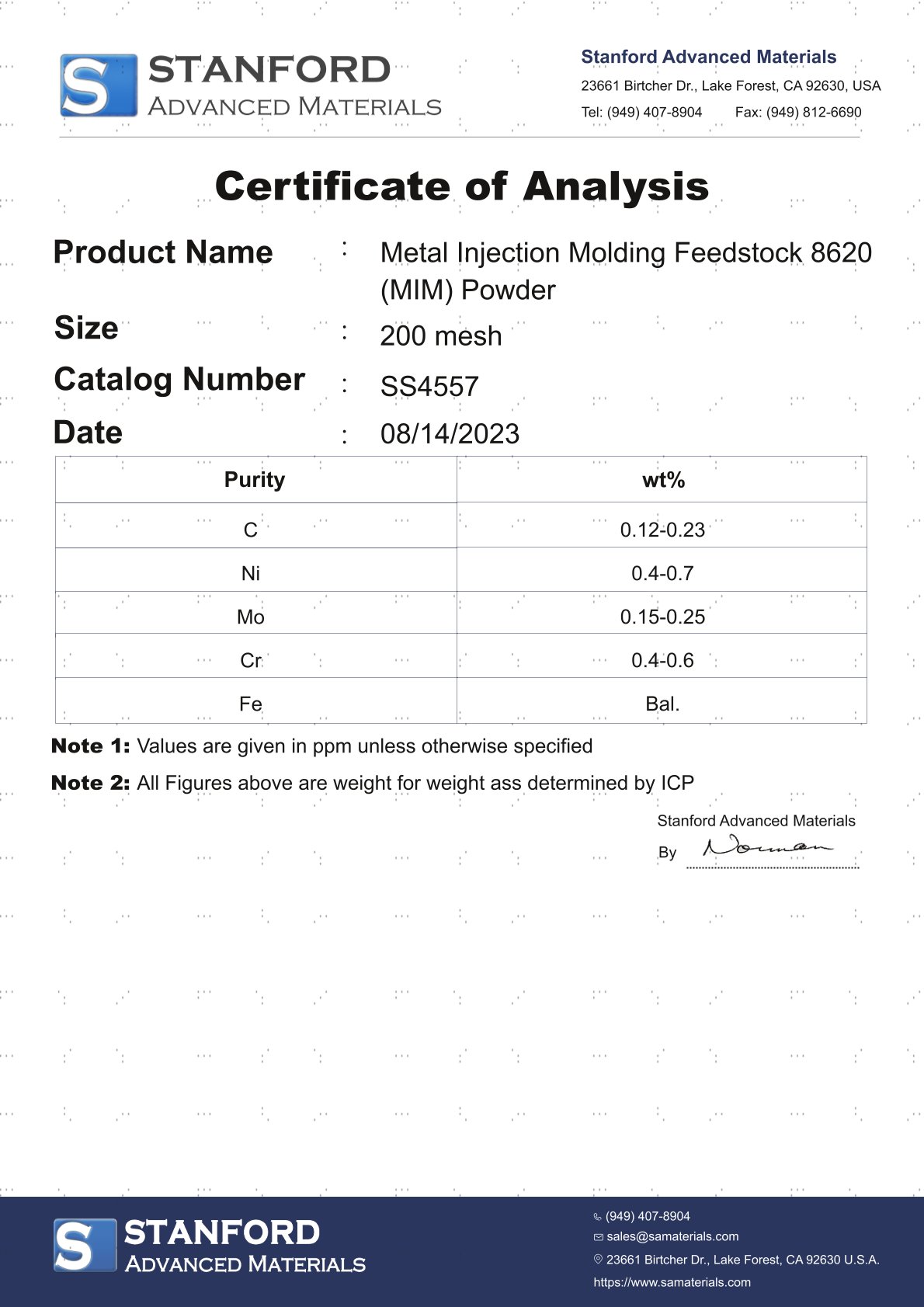

SS4557 Metal Injection Molding Feedstock 8620 (MIM) Powder

| Catalog No. | SS4557 |

| Material | 8620 |

| MFI (g/10min) | ≥600 |

| Sintered density (g/cm3) | ≥7.45 |

Metal Injection Molding Feedstock 8620 (MIM) is manufactured by mixing fine metal powder with waxes and polymers to create the foundation for what will become the MIM part. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Metal Injection Molding Feedstock 8620 (MIM).

Related products: Metal Injection Molding Feedstock 316L (MIM), Metal Injection Molding Feedstock 304L (MIM), Metal Injection Molding Feedstock 420 (MIM)

LATEST RECOMMENDED

.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!