- Products

- Categories

- Blog

- Podcast

- Application

- Document

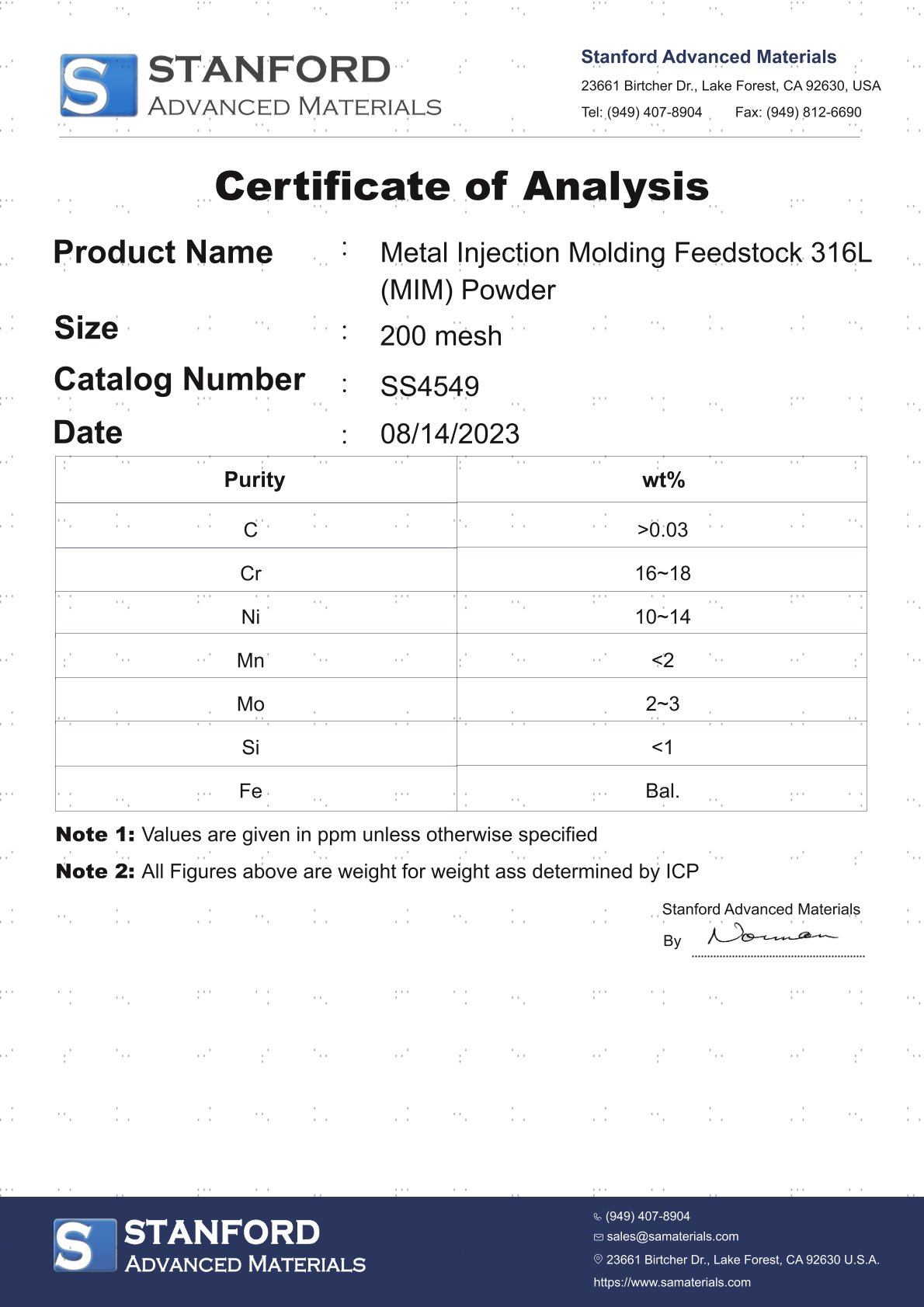

SS4549 Metal Injection Molding Feedstock 316L (MIM) Powder

| Catalog No. | SS4549 |

| Material | 316L |

| MFI (g/10min) | ≥600 |

| Sintered density (g/cm3) | ≥7.8 |

Metal Injection Molding Feedstock 316L (MIM) is used directly as raw material pellets for injection molding for the production of 316L austenitic stainless steel sintered parts. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Metal Injection Molding Feedstock 316L (MIM).

Related products: Metal Injection Molding Feedstock 17-4PH (MIM), Metal Injection Molding Feedstock 304L (MIM), Metal Injection Molding Feedstock 420 (MIM)

LATEST RECOMMENDED

.jpg)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!