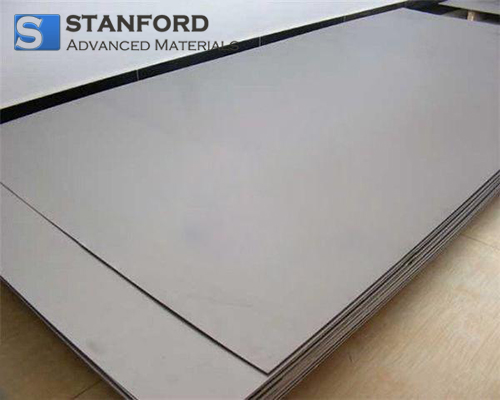

TM3415 Medical Grade Titanium Plate

| Catalog No. | TM3415 |

| Material | Ti |

| Size | W 100-1000mm, T 0.3-4.5mm, L 200-1500mm |

| Purity | 99.9% |

Stanford Advanced Materials (SAM) manufactures a range of Medical Grade Titanium Plates, in standard sizes and in square, rectangular or circular shapes. Custom Titanium products are also available according to your requirements.

Related products: Medical Grade Titanium Alloy Plate, Medical Grade Titanium Rod, Medical Grade Titanium Tube, Medical Grade Titanium Foil, Medical Grade Titanium Wire

Medical Grade Titanium Plate Description

Medical Grade Titanium Plate has been used for decades in the pharmaceutical industry, surgical instruments, human implants and other fields in the US and the world, and has achieved great success. Medical Grade Titanium Plate is used in medical devices, prostheses or adjuvant therapeutic devices, characterized by an elastic modulus close to that of natural bone.

Medical Grade Titanium Plate Specifications

Physical Properties:

|

Physical Properties |

Tensile Strength |

yield Strength |

Elongation |

Section Shrinkage |

|

Unit |

Mpa |

Mpa |

% |

% |

|

Ti-G1 |

240 |

170 |

25 |

30 |

|

Ti-G2 |

345 |

275 |

20 |

30 |

Chemical Composition:

|

Type |

Chemical Composition (wt%) |

|||||

|

N≤ |

C≤ |

H≤ |

Fe≤ |

O≤ |

Others≤ |

|

|

Ti-G1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

0.40 |

|

Ti-G2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

0.40 |

Benefits of Medical Titanium:

-Strong

-Lightweight

-Corrosion Resistant

-Cost-efficient

-Non-toxic

-Biocompatible (non-toxic AND not rejected by the body)

-Long-lasting

-Non-ferromagnetic

-Osseointegrated (the joining of bone with artificial implant)

-Long range availability

-Flexibility and elasticity rivals that of human bone

Medical Grade Titanium Plate Applications

Medical Grade Titanium Plates are used in surgery, which includes:

-Orthopedic pins and screws

-Orthopedic cables

-Ligature clips

-Surgical staples

-Springs

-Orthodontic appliances

-In joint replacements

-Cryogenic vessels

-Bone fixation devices

Medical Grade Titanium Plate Packaging

Our Medical Grade Titanium Plates are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!