PC0155 Cast Titanium Alloy (Cast Ti Alloy)

| Catalog No. | PC0155 |

| Size | Manufactured per drawing |

| Density | 4.5-4.51 g/cc |

| Material | C.P. Titanium Ti-6Al-4V |

| MSDS/SDS |

Discover Cast Titanium Alloys on the Stanford Advanced Materials platform, offering high-strength, lightweight solutions for aerospace, medical, and industrial applications.

Related products: Titanium Fitting, Titanium Flange

Cast Titanium Alloy (Cast Ti Alloy) Description

Cast Titanium alloy has equal ultimate strength as cast steel alloy but has many other superior characteristics.

- The density of only 4.5, much lower compared with 7.8 for steel;

- Heat resistance up to 400°C/500°C;

- Higher corrosion resistance;

- Bio-compatibility (no rejection by the human body)

Titanium alloys are melted in vacuum skull furnaces and can be cast to many designations of pumps, valve impellers, artificial joints, and machines of other shapes. X-ray inspections are applied in all casting processes by good manufacturing practices. Stanford Advanced Materials can produce custom Titanium precision castings according to your drawings and specifications.

Cast Titanium Alloy Specification

|

Size |

Manufactured per drawing |

|

Density |

4.5-4.51 g/cc |

|

Yield Strength |

800-1000MPa |

|

Tensile Strength |

1000-1200MPa |

|

Hardness |

200-400HBW |

|

Material |

C.P. Titanium Ti-6Al-4V |

Introduction of Casting Methods

Machined graphite mold casting

This method can simplify molding and effectively control metallurgical quality. Thicker and larger size castings can be precisely made by this method.

Ceramic mold investment casting

This method produces more precise castings, with details such as logos cast. Large-sized and complex shape parts can be well cast using this method.

For further information, please feel free to contact our experts!

Cast Titanium Alloy Applications

1. Aerospace: Used in aircraft components like engine parts, landing gear, and structural elements due to their high strength-to-weight ratio and resistance to corrosion.

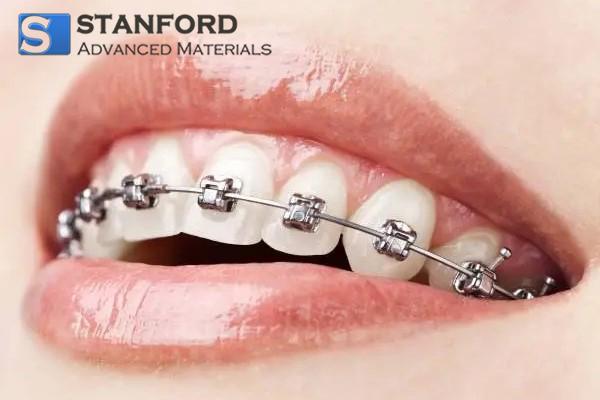

2. Medical: Employed in the manufacturing of medical implants such as hip and knee replacements, bone plates, and dental implants due to their biocompatibility and corrosion resistance.

3. Automotive: Utilized in automotive components like exhaust systems, valve components, and suspension parts for their lightweight properties and durability.

4. Industrial: Used in various industrial equipment and machinery components requiring high strength, corrosion resistance, and heat resistance.

5. Marine: Applied in marine applications such as boat propellers, shafts, and valves due to their resistance to corrosion in saltwater environments.

6. Sporting Goods: Integrated into sporting equipment like bicycle frames, golf clubs, and racing car components for their lightweight and high-performance properties.

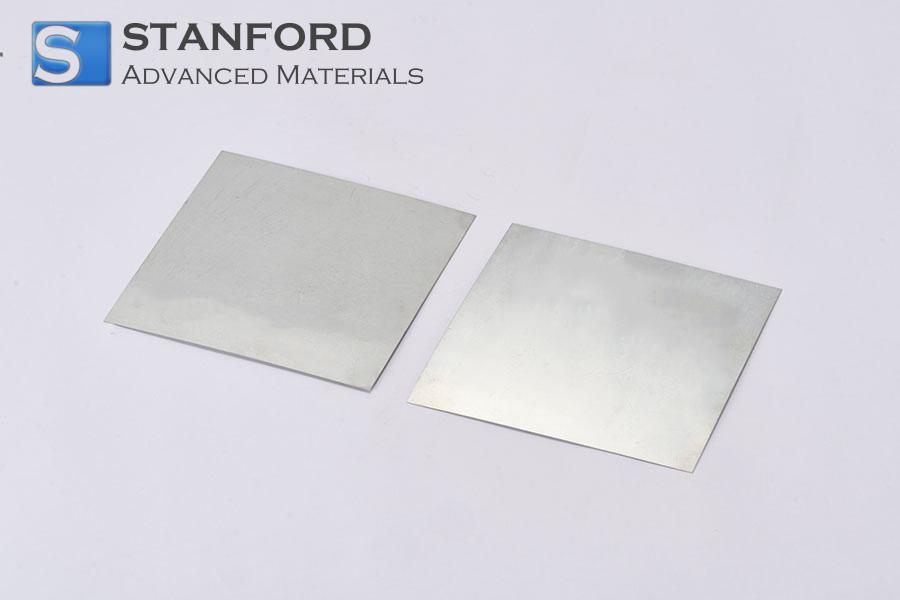

Packaging of SAM Cast Titanium Alloy

Our cast Ti alloys are tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!