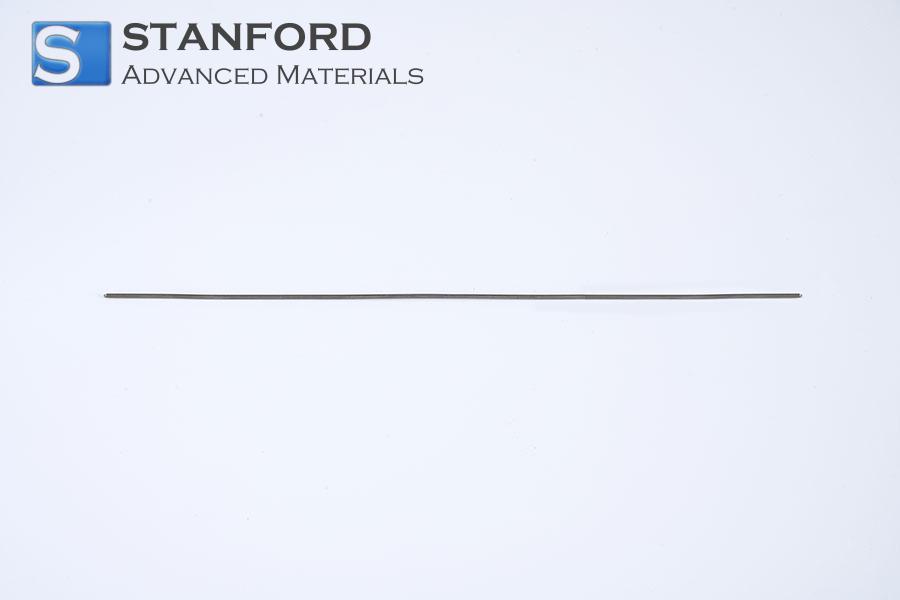

TM0157 Titanium Wire (Ti Wire)

| Catalog No. | TM0157 |

| Size | Customized |

| Material | C.P.Titanium Ti Alloys |

| Standard | ASTM B863 AWS A5.16 ASTM F136 ASTM F67 |

| Density | 4.5-4.51 g/cc |

| Surface | Pickled, Polished (Dia.>1.0mm) |

| MSDS/SDS |

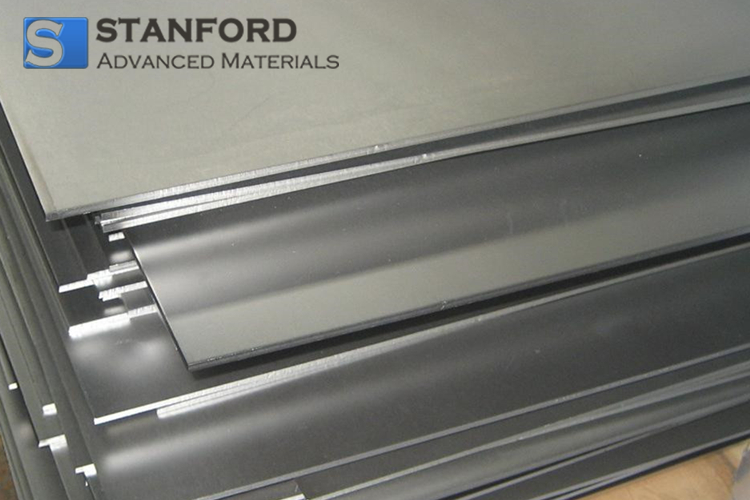

Titanium Wire, renowned for its versatility and durability, finds widespread applications in aerospace, medical, and industrial sectors. With excellent corrosion resistance and high strength-to-weight ratio, titanium wire is vital for crafting surgical implants, aircraft components, and chemical processing equipment.

Related products: Titanium plate, Titanium tube

Titanium Wire Description

Titanium Wire is celebrated for its exceptional properties, making it indispensable in various industries. Renowned for its remarkable strength, corrosion resistance, and lightweight nature, Titanium Wire finds extensive applications in aerospace, medical, and industrial sectors. Its high strength-to-weight ratio makes it ideal for aircraft components and surgical implants, ensuring reliability and durability. Additionally, Titanium Wire exhibits superb resistance to corrosion, making it suitable for chemical processing equipment and marine applications. With its versatility and reliability, titanium wire continues to be a preferred choice for demanding engineering challenges where strength, durability, and resistance to corrosion are paramount.

Titanium Wire Specification

|

Form |

Standard |

Grade |

Dia. (mm) |

Surface |

|

Straight Wire |

ASTM B863 |

Gr.1, Gr.2, Gr.3, Gr.4 |

1.0-5.0 |

Pickled, Polished, Customized |

|

Coiled Wire |

0.5-5.0 |

|||

|

Welding Wire |

AWS 5.16 |

ERTi-1, ERTi-2, ERTi-5, ERTi-9 |

0.5-5.0 |

Chemical Composition

|

Element |

N |

C |

H |

Fe |

O |

Residuals |

Ti |

|

Grade 1 |

0.03 |

0.08 |

0.01 |

0.2 |

0.18 |

0.4 |

Bal. |

|

Grade 2 |

0.03 |

0.08 |

0.015 |

0.25 |

0.25 |

0.4 |

Bal. |

|

Grade 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

0.4 |

Bal. |

|

Grade 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

0.4 |

Bal. |

Titanium Wire Production

Our titanium wire is drawn from forged rods. SAM operates a strict quality control process using ASTM grades of titanium to ensure no contamination.

Titanium Wire Applications

1. Aerospace: Essential for aircraft components such as fasteners, springs, and electrical connectors due to its high strength-to-weight ratio and resistance to corrosion.

2. Medical: Used in surgical implants like bone screws, dental wires, and cardiovascular stents due to its biocompatibility and resistance to bodily fluids.

3. Chemical Processing: Employed equipment for handling corrosive chemicals and acids, such as valves, fittings, and mesh screens, due to their corrosion resistance.

4. Electronics: Utilized in electronic devices for wire bonding, connectors, and antennas due to its conductivity and resistance to corrosion.

5. Jewelry: Found in high-end jewelry for its hypoallergenic properties, durability, and ability to be colored through anodizing.

6. Art and Design: Used by artists and designers for sculptural works and architectural installations due to its malleability and aesthetic appeal.

7. Automotive: Employed in automotive applications such as exhaust systems, springs, and suspension components for their lightweight and high strength.

8. Sports and Recreation: Utilized in sports equipment such as bicycle frames, fishing rods, and golf club shafts for its lightweight and durable properties.

Titanium Wire Packaging And Shipping

Stanford Advanced Materials is a leading titanium wire supplier. Our titanium wires are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

Related articles:

CP Titanium – Commercially Pure Titanium (1)

CP Titanium – Commercially Pure Titanium (2)

Titanium Used in the Aerospace Industry

Medical Grade Titanium Materials - Indispensable to the Medical Industry

Application of Titanium in Watch

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!