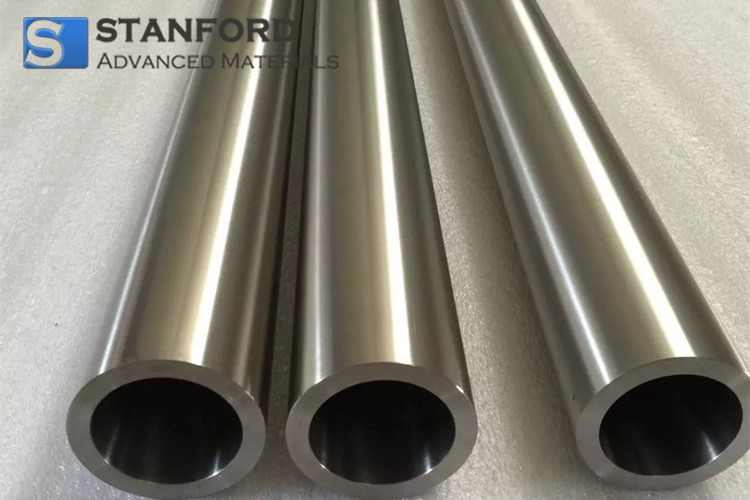

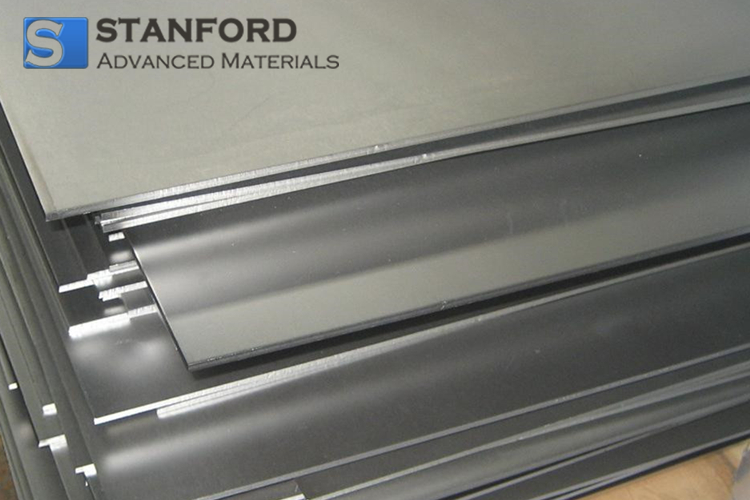

Titanium Tube Description

Titanium Tube (Ti Tube) is one of the common titanium products and has a superior strength-to-weight ratio and corrosion resistance. We generally divide titanium tubes into two types, one is called the seamless titanium tube, and the other is called the welded titanium tube.

Titanium tubes are light in weight, high in strength, and superior in mechanical properties. They are widely used in heat exchange equipment, such as tube and tube heat exchangers, coil heat exchangers, serpentine tube heat exchangers, condensers, evaporators, and conveying pipelines, etc.

Stanford Advanced Materials (SAM) is a trust-worthy supplier of high-quality Titanium Tube (Ti Tube) that has over two decades in the manufacture and sale of titanium products.

Titanium Tube Specifications

-Standard:ASTM B337, ASTM SB338, ASTM B861

-Materials: Gr.1, Gr.2, Gr.9

-Surface: Pickled or Polished

-Customization available upon request

Titanium Seamless Tube

-Outside Diameter:3.18mm-50.8mm

-Thickness: 0.6mm-1.66mm

-Length: up to 15000mm

Titanium Welded Tube

-Outside Diameter: 3.18mm-38.1mm

-Thickness: 0.5mm-50mm

-Length: up to 15000mm

Titanium Tube Production Methods

Titanium Seamless Tube: Extruded pipe blanks are cold-rolled and annealed.

Titanium Welded Tube: Made from titanium strip.

Titanium Tube Applications

1. Aerospace: Used in aircraft structures, engine components, and hydraulic systems due to their high strength-to-weight ratio and resistance to corrosion.

2. Medical: Employed in medical implants such as bone plates, dental implants, and surgical instruments due to their biocompatibility and corrosion resistance.

3. Chemical Processing: Utilized in chemical reactors, heat exchangers, and piping systems due to their resistance to corrosion by acids and chemicals.

4. Power Generation: Found in power plants for heat exchangers, condensers, and steam turbine components due to their high-temperature strength and corrosion resistance.

5. Oil and Gas Industry: Used in offshore drilling rigs, subsea pipelines, and refinery equipment due to their resistance to corrosion in harsh environments.

6. Automotive: Employed in exhaust systems, hydraulic lines, and suspension components for their lightweight nature and resistance to high temperatures and corrosion.

7. Sports and Recreation: Utilized in bicycle frames, golf club shafts, and marine equipment due to their lightweight and durable properties.

8. Architectural Design: Found in architectural structures such as handrails, support beams, and artistic installations for their aesthetic appeal and durability.

Titanium Tube Packaging & Shipping

Our Titanium Tubes are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

Specification

Titanium Tube Specifications

-Standard: ASTM B337, ASTM SB338, ASTM B861

-Materials: Gr.1, Gr.2, Gr.9

-Surface: Pickled or Polished

-Customization available upon request

Titanium Seamless Tube

-Outside Diameter:3.18mm-50.8mm

-Thickness: 0.6mm-1.66mm

-Length: up to 15000mm

Titanium Welded Tube

-Outside Diameter: 3.18mm-38.1mm

-Thickness: 0.5mm-50mm

-Length: up to 15000mm